Livestock and poultry feed production technology for granulating powder at low temperature after conditioning and baking process of powder

A livestock and poultry feed, tempering technology, applied in feed, food forming, food science, etc., can solve the problems of heat-sensitive feed additive activity loss, affecting feed digestion and absorption rate, affecting feed safety, etc., to overcome heat-sensitive groups Severe loss of points, reduction of equipment configuration costs, improvement of digestibility and utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

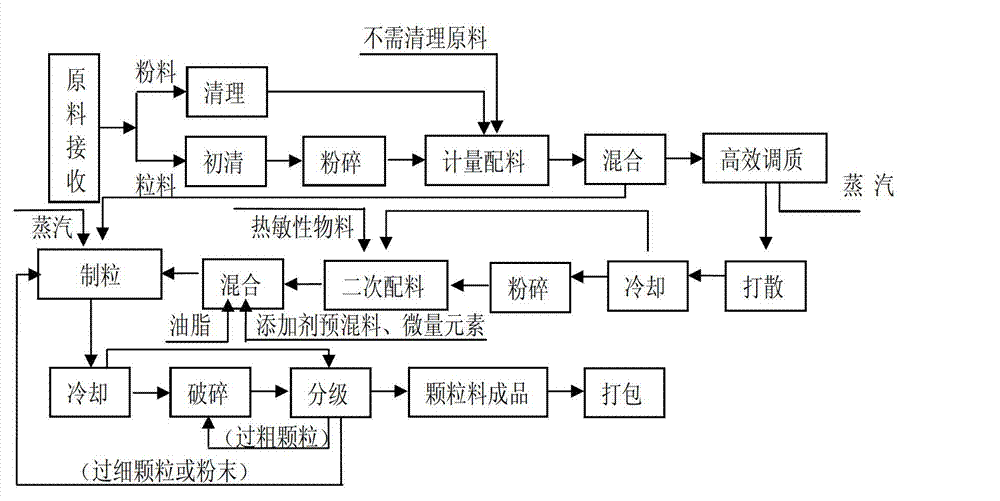

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Production of high-grade livestock and poultry pellets and mature powdered feed by low-temperature granulation process after powder conditioning and aging

[0041] (1) Raw material receiving and cleaning

[0042] The pellets (such as corn and soybean meal) are unloaded into the feeding pit, and after being cleaned and screened by the cylinder to remove large impurities, they enter the permanent magnetic cylinder to remove iron impurities, and then enter the bin to be crushed. For the powdery materials that do not need to be crushed, they enter the powder cleaning sieve and the permanent magnetic cylinder through the discharge pit, remove the large and iron impurities in the powdery raw materials, and then enter the batching bin.

[0043] (2) Crushing of raw materials

[0044] The impurity-cleaned pellets enter different pulverizers for crushing, and the pulverized materials are conveyed by screw conveyors respectively, enter their own dedicated bucket elevato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com