Continuous mixing system for preparing impervious soil and control method

A preparation system and soil material technology, which is applied to clay preparation devices, mixing operation control, mixing plants, etc., can solve the problems of large mixing sites, difficult quality control, and affecting the strength of filling construction, etc., to save equipment and site costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

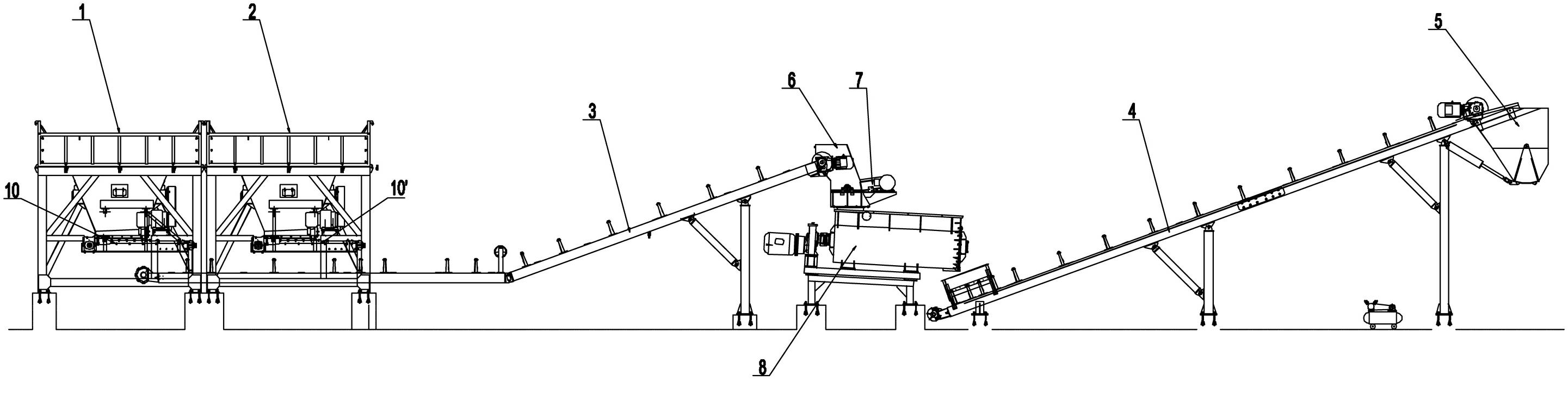

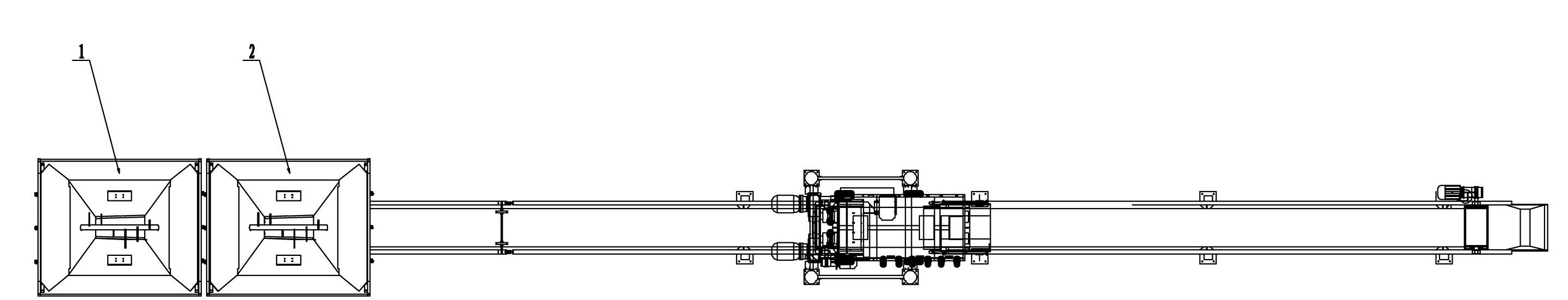

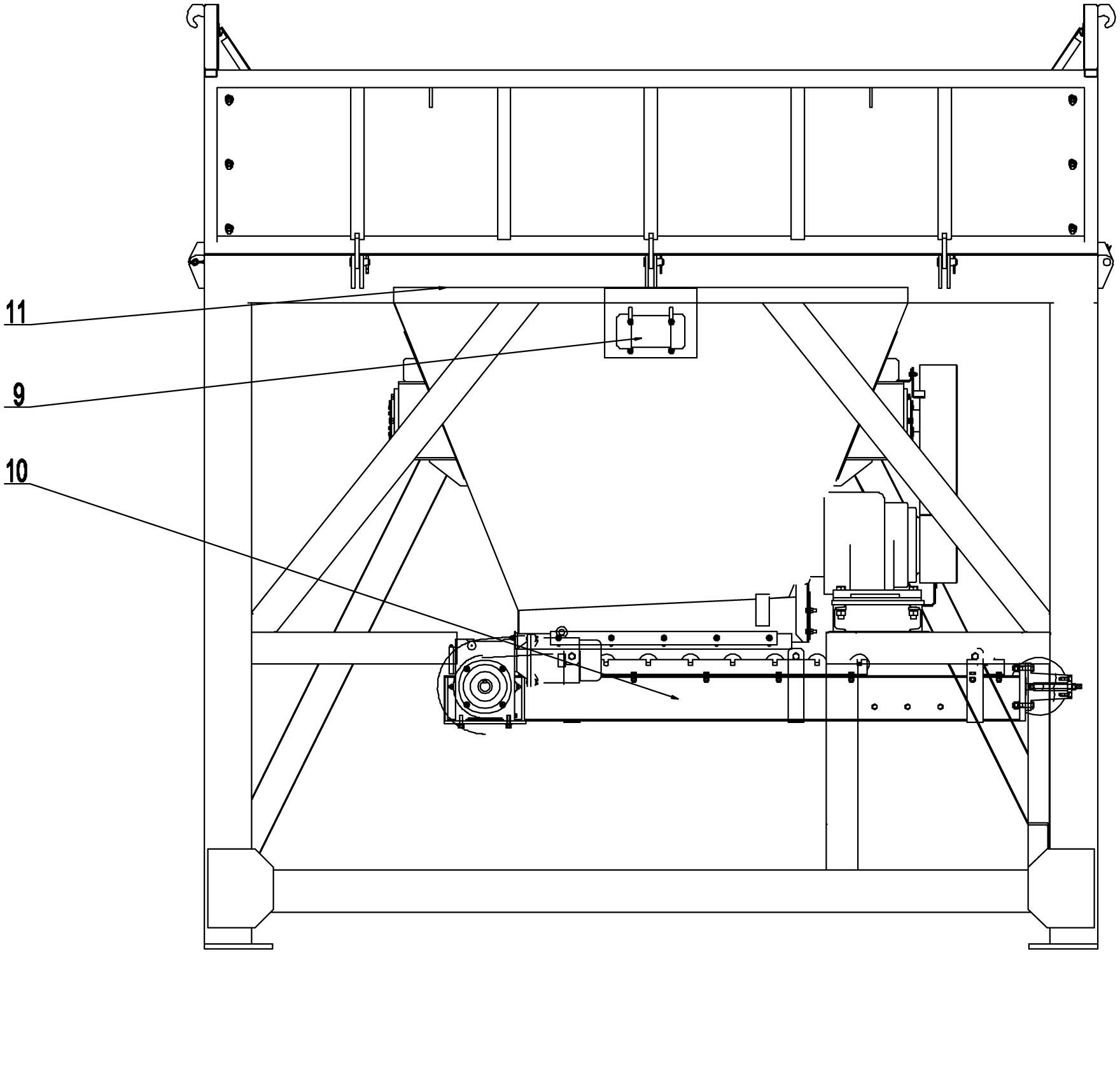

[0031] Such as figure 1 , figure 2 Among them, a continuous stirring and anti-seepage soil material mixing preparation system, the clay hopper 1 and the gravel hopper 2 are provided with an aggregate batching belt conveyor 3, the aggregate batching belt conveyor 3 is connected with the metering hopper 6, and the metering hopper 6 is provided with There is a continuous mixer 8, the discharge port of the continuous mixer 8 is provided with a lifting discharge belt conveyor 4, and the lifting discharge belt conveyor 4 is connected with the discharge hopper 5, and the continuous mixer 8 is also provided with a water supply device 7.

[0032] The metering hopper 6 is provided with a pressure sensor. The pressure sensor can provide a signal to the main control device, such as PLC or industrial computer, to obtain the weight of the material in the weighing hopper 6, so as to supply water according to the weight.

[0033] The continuous mixer 8 is a twin-shaft forced continuous mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com