Automatic material blending device

A technology for automatic batching and feeding, which is used in food science and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

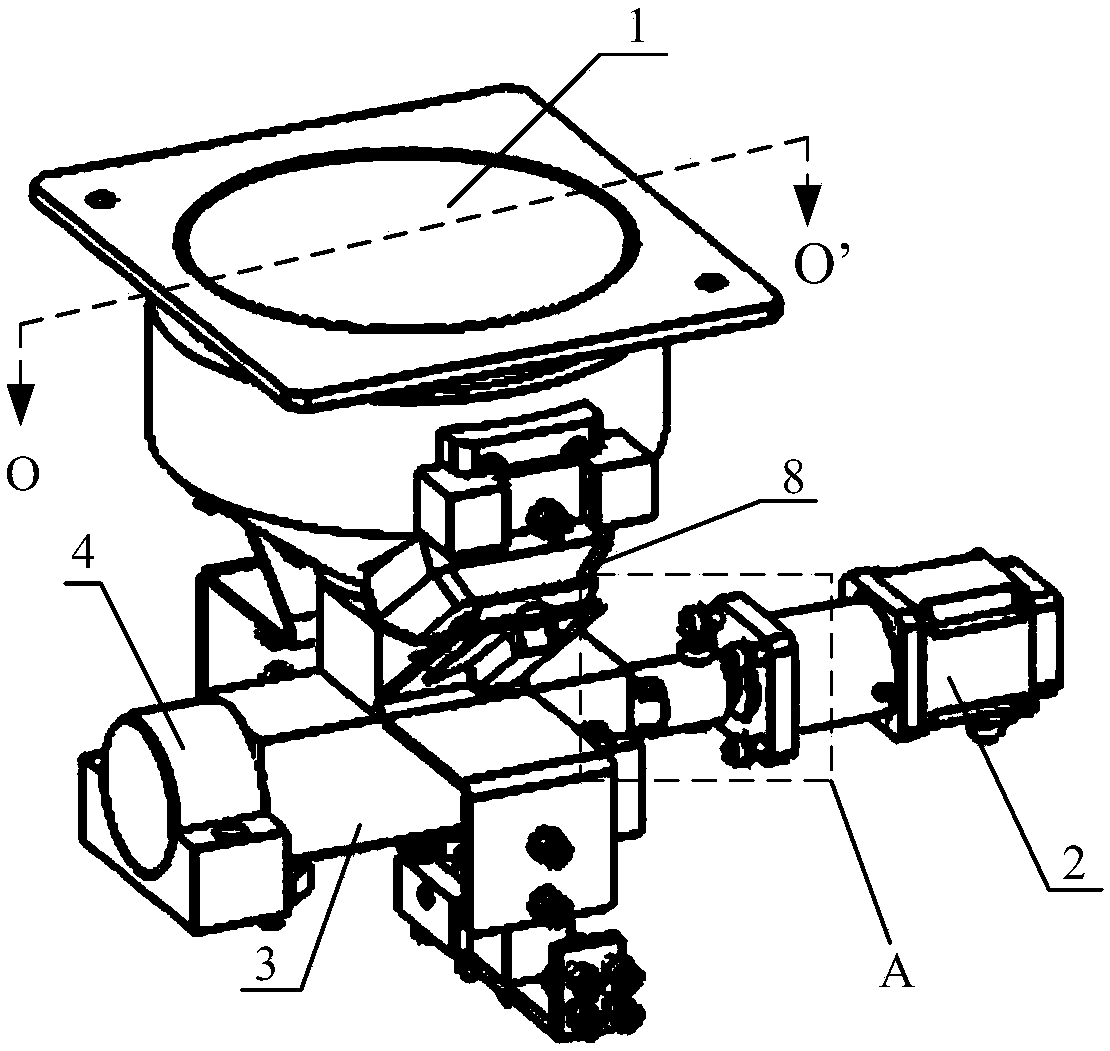

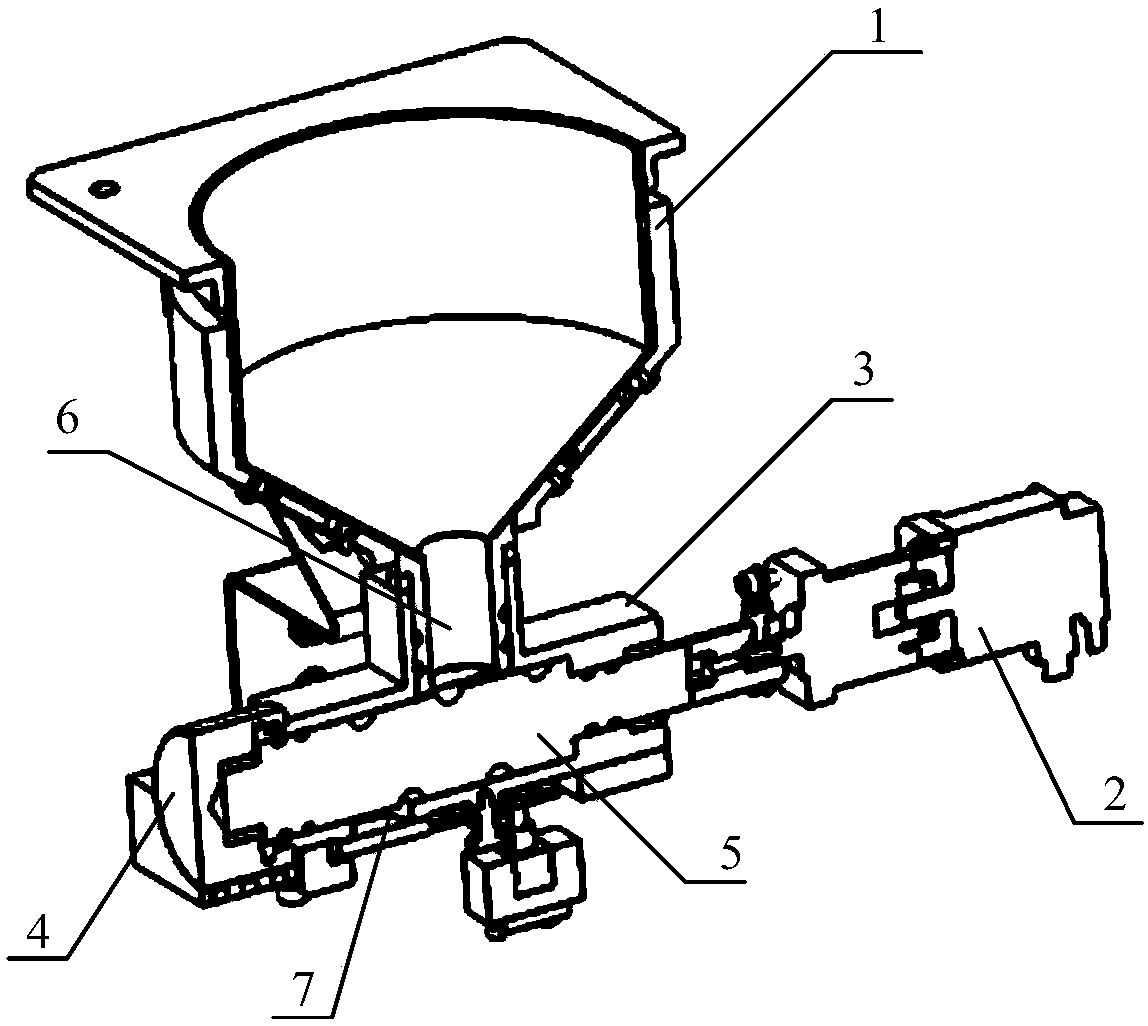

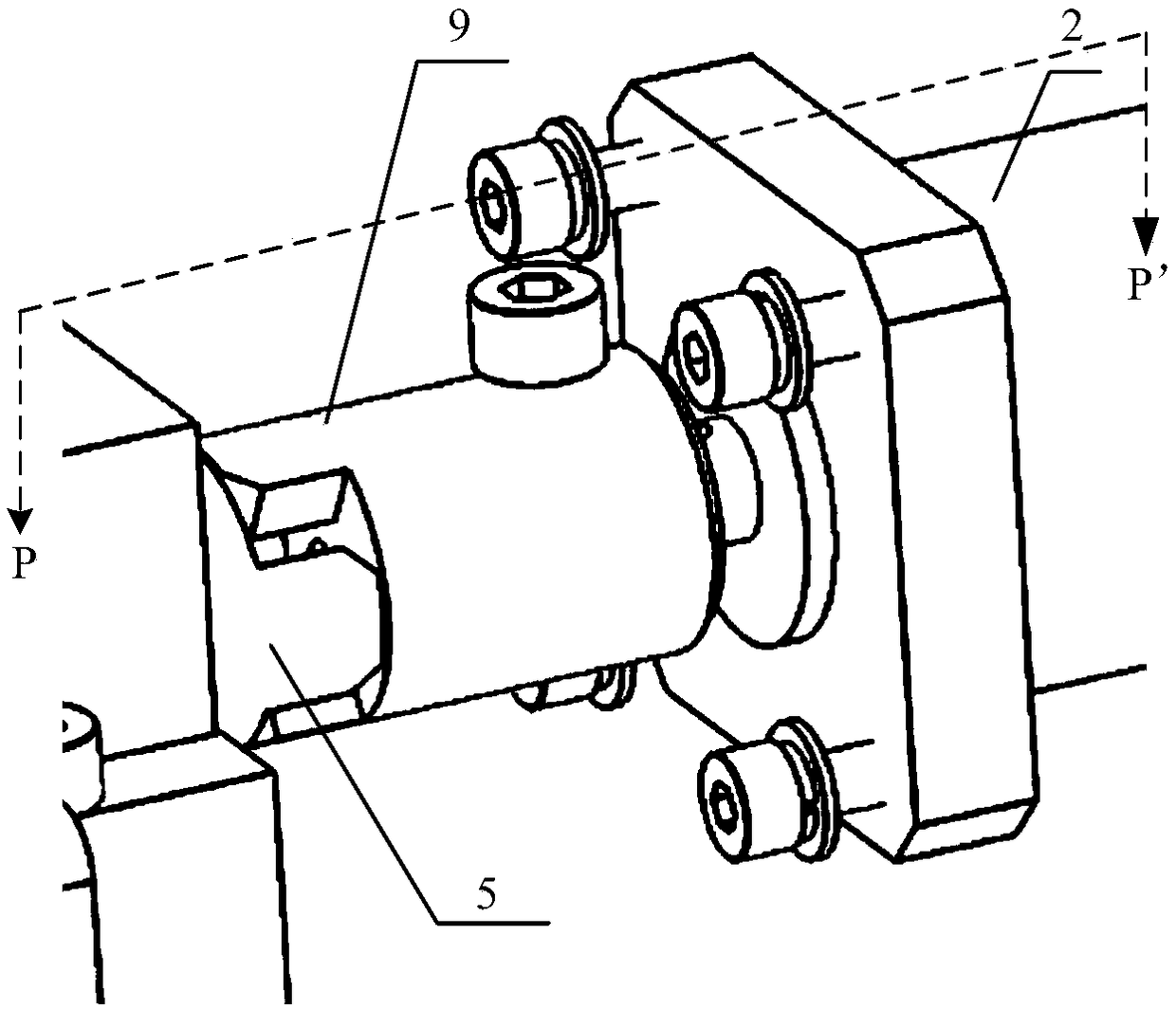

[0030] The automatic batching device of the embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] The embodiment of the present invention provides an automatic batching device, such as figure 1 with figure 2 As shown, the automatic batching device includes a material storage tank 1, a controller, and a material delivery mechanism located below the material storage tank 1; wherein, the material delivery mechanism includes a drive motor 2 and a material delivery tube 3, and the delivery tube 3 is sleeved There is a screw 5, which is connected with the rotating shaft of the driving motor 2, and the screw thread of the screw 5 is in clearance fit with the inner wall of the feeding tube 3; Feeding port 6, on the side wall of the feeding cylinder 3, a lower discharging port 7 is provided on the side away from the driving motor 2, and a base for placing a material receiving container is arranged below the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com