Automatic proportioning type cement hopper

An automatic batching and cement technology, which is applied to cement mixing devices, unloading devices, and raw material supply devices for sale, etc., can solve the problems of clogging hoppers, prone to errors, and excessive feeding preset values, so as to avoid leakage and reduce work. amount of effect

Inactive Publication Date: 2018-07-24

苏州相城埭辰科技产业发展有限公司

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there is a hopper that can be weighed. A weighing sensor and a weighing controller connected to it are installed on the hopper. The material in the hopper enters the next link after continuous weighing. After the weight reaches the requirement, the weighing sensor Send a signal to the weighing controller, and the weighing controller controls the feeding mechanism to stop feeding, which takes a certain amount of time to respond, so it often causes the actual feeding to exceed the preset value, so errors are prone to occur

[0003] Secondly, in the mixing process of cement production, because the semi-finished cement is very viscous, when the hopper is mixed and falls, it is easy to arch or block the hopper, so that the subsequent cement cannot fall along the hopper

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

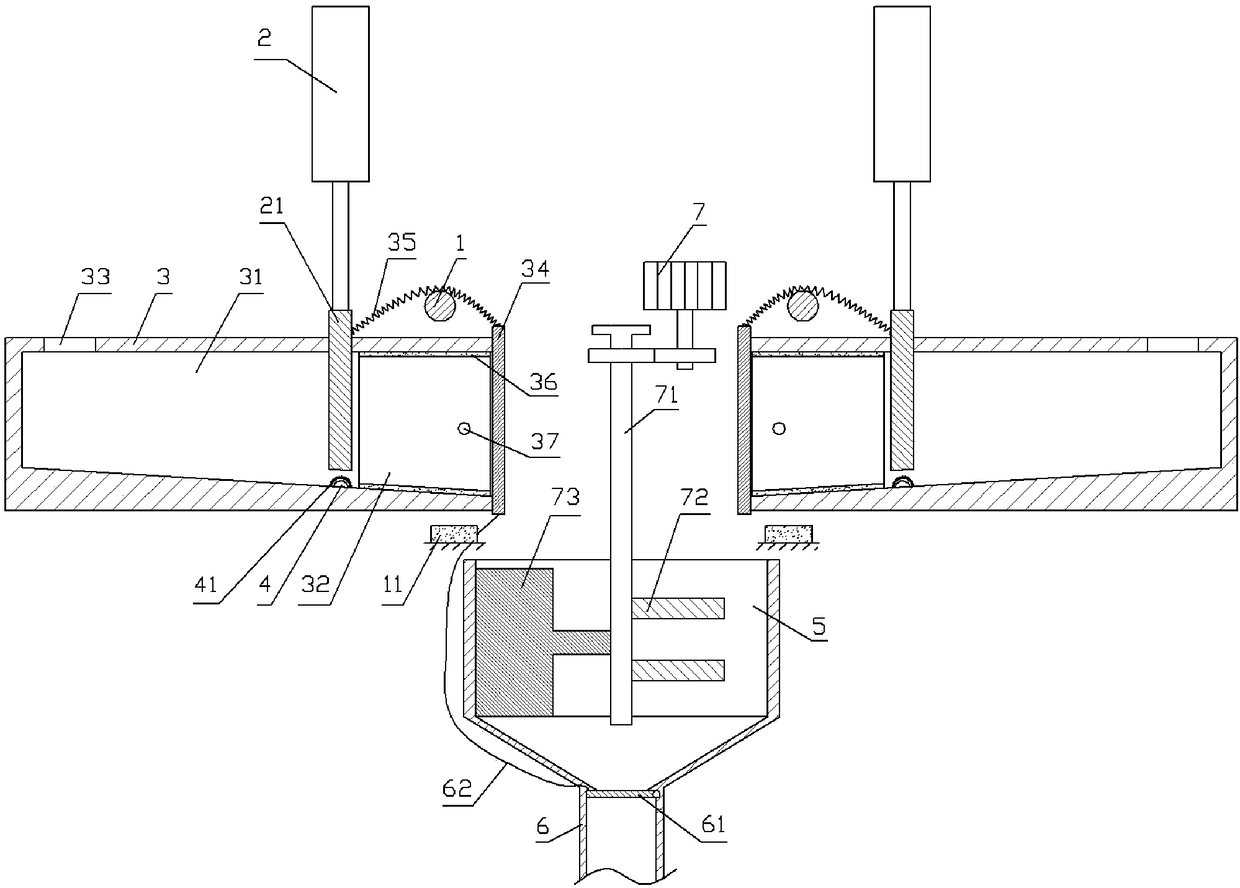

The invention relates to the field of buildings and in particular discloses an automatic proportioning type cement hopper. The automatic proportioning type cement hopper comprises a rack, a stirring mechanism, a feeding hopper and a proportioning mechanism, wherein the feeding holler comprises a feeding part and a discharging pipe; a sealing plate is hinged to the upper part of the discharging pipe; a pull rope is fixed on the sealing plate; the stirring mechanism comprises a motor, a stirring shaft and stirring blades; one end of the stirring shaft and the stirring blades are arranged in thefeeding part; the proportioning mechanism comprises an extension spring, a separating plate, a hydraulic jacking device, an electromagnet, a proportioning box and a baffle plate; the pull rope is fixedly arranged on the baffle plate; the proportioning box is divided into a proportioning cabin and a feeding cabin by the separating plate; two ends of the extension spring are fixedly arranged on thebaffle plate and the separating plate respectively; the bottom of the proportioning box is an inclined surface; the electromagnet can adsorb the baffle plate; a switch is arranged on an inner wall ofthe proportioning box; the separating plate can press the switch; an airbag is fixedly arranged at the bottom of the proportioning cabin; an air inlet is formed in the airbag; a feeding opening is formed in a lateral wall of the feeding cabin. By adopting the automatic proportioning type cement hopper provided by the invention, the quantity of entered raw materials can be controlled.

Description

technical field [0001] The invention relates to the construction field, in particular to a cement hopper. Background technique [0002] In the field of construction, cement hoppers are widely used, and cement hoppers are mainly used in the production process of cement. At present, there is a hopper that can be weighed. A weighing sensor and a weighing controller connected to it are installed on the hopper. The material in the hopper enters the next link after continuous weighing. After the weight reaches the requirement, the weighing sensor Send a signal to the weighing controller, and the weighing controller controls the feeding mechanism to stop feeding, which takes a certain amount of time to respond, so it often causes the actual feeding to exceed the preset value, so errors are prone to occur. [0003] Secondly, during the mixing process of cement production, because the semi-finished cement is very viscous, when the hopper is mixed and falls, it is easy to arch or blo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B28C7/14B28C7/06B28C7/16B28C5/16

CPCB28C5/16B28C7/067B28C7/14B28C7/16

Inventor 廖成涛

Owner 苏州相城埭辰科技产业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com