High-temperature alloy machining tool and application thereof

A technology for superalloys and machining tools, applied in the field of material processing, can solve the problems of easy chipping and reduce the toughness of the matrix, and achieve excellent metallurgical properties, obvious effects, and the effect of promoting technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

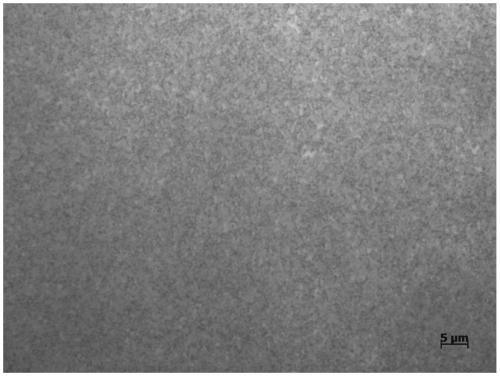

Embodiment 1

[0046] Example 1 A superalloy cutting tool produced according to an exemplary embodiment of the present invention, the substrate has a composition of 11.5% by weight of Co, 0.85% by weight of Cr, 87% by weight of WC, 0.6% by weight of Rare metal, the balance is other unavoidable impurity components, in this embodiment, the rare metal element is a mixture of La and Tb with a mass percentage of 1:2. Substrates from which cutting tools are subsequently fabricated are produced by conventional grinding of powders, pressing green compacts and sintering. The microstructure of the sintered substrate was studied, and the average intercept length of the tungsten carbide phase was measured to be 0.50 μm. The mechanical / mechanical properties of the substrate were tested, and the following parameters were measured: coercive force 206Oe, bending strength 4582MPa, Fracture toughness 18.6MPam 1 / 2 .

Embodiment 2

[0048] Example 2 A superalloy cutting tool manufactured according to an exemplary embodiment of the present invention has a substrate with a composition of 12.8% by weight of Co, 0.95% by weight of Cr, 1.5% by weight of rare metals, and the balance is WC and other unavoidable impurity components, in this embodiment, the rare metal elements are Re and Dy with a mass percentage of 1:3. Substrates from which cutting tools are subsequently fabricated are produced by conventional grinding of powders, pressing green compacts and sintering. The microstructure of the sintered substrate was studied, and the average intercept length of the tungsten carbide phase was measured to be 0.56 μm. The mechanical / mechanical properties of the substrate were tested, and the following parameters were measured: coercive force 212Oe, bending strength 4986MPa, Fracture toughness 19.1MPam 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com