Admixture production system and admixture production process

A production system and admixture technology, applied in the field of admixture production system and admixture production process, can solve the problems of uneven quality of superfine admixtures, and achieve high production efficiency, improved quality, and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

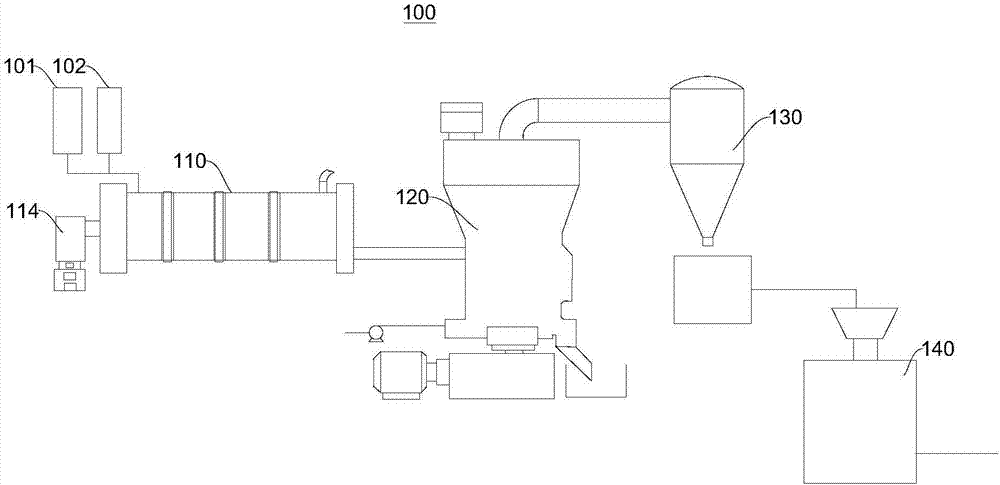

[0031] figure 1 For the structural schematic diagram of the admixture production system 100 provided by the embodiment of the present invention, please refer to figure 1 , this embodiment provides an admixture production system 100 . The admixture production system 100 includes a drying mechanism 110 , a grinding mechanism 120 , and a sorting mechanism 130 connected in sequence. The outlet 121 of grinding mechanism 120 (see Figure 5 ) communicates with the sorting mechanism 130, the outlet 121 is equipped with a door 122, and the door 122 is slidingly connected with the housing 123 of the grinding mechanism 120 to adjust the size of the outlet 121.

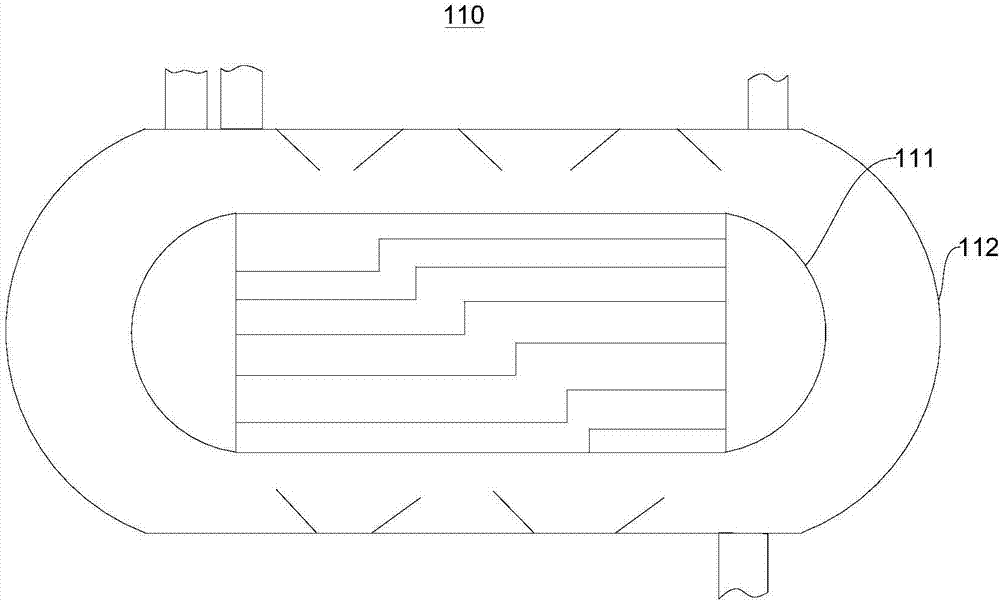

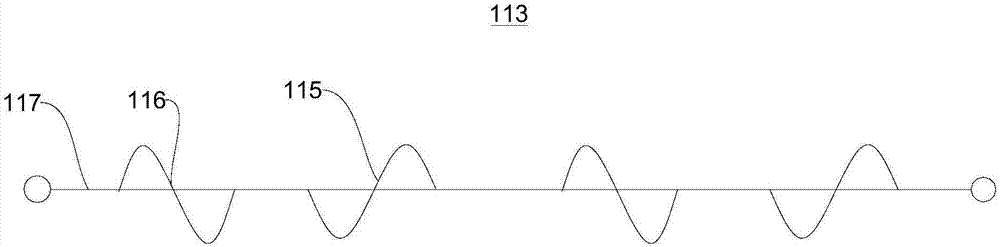

[0032] specifically, figure 2 For the schematic structural diagram of the drying mechanism 110 provided by the embodiment of the present invention, please refer to figure 2 . In this embodiment, the drying mechanism 110 includes an inner cylinder 111 , an outer cylinder 112 , a turning device 113 , and a power device 114 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com