Preparation method of boehmite

A boehmite and hydrolysis technology, which is applied in the preparation of alumina/hydroxide, chemical instruments and methods, and aluminum compounds, etc., can solve the problem of irregular powder particle morphology, low initial thermal decomposition temperature, primary particle Large particle size and other problems, to achieve the effect of good crystallization performance, good working conditions and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] If 1kg of cubic blocky boehmite powder is prepared, the proportions of the ingredients in the preparation formula are as follows:

[0031] The aluminum hydroxide powder obtained by the direct hydrolysis method of 1 kg of aluminum, 2.5 liters of water, the specific preparation process is as follows:

[0032] In the first step, add 1kg of aluminum hydroxide powder into a 4-liter hydrothermal reaction kettle, add 2.5 liters of water, and stir evenly.

[0033] In the second step, heat the reactor to 140° C., and heat-treat for 12 hours under stirring conditions.

[0034] The third step is to cool down to room temperature naturally under reduced pressure, and filter through a filter cloth to form a filter cake.

[0035] In the fourth step, the filter cake is beaten and spray-dried to obtain aluminum hydroxide powder.

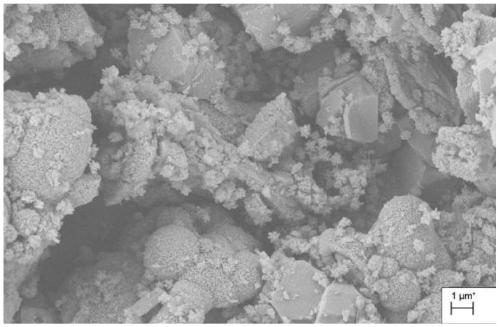

[0036] In the 5th step, the aluminum hydroxide obtained is weighed and packed (see image 3 , Figure 4 ).

Embodiment 2

[0038] If 1kg of flake-shaped aluminum hydroxide powder is prepared, the proportions of ingredients in the preparation formula are as follows:

[0039] The aluminum hydroxide powder obtained by 1kg kind of method, 2.5 liters of Virahol, the specific preparation process is as follows:

[0040] In the first step, add 1 kg of aluminum hydroxide powder into a 4 liter hydrothermal reaction kettle, add 2.5 liters of isopropanol, and stir evenly.

[0041] In the second step, heat the reactor to 140° C., and heat-treat for 12 hours under stirring conditions.

[0042] The third step is to cool down to room temperature naturally under reduced pressure, and filter through a filter cloth to form a filter cake.

[0043] In the fourth step, the filter cake is beaten and spray-dried to obtain aluminum hydroxide powder.

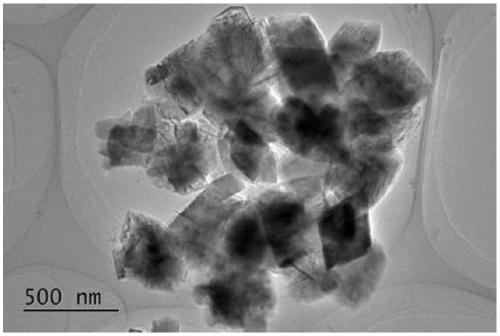

[0044] In the 5th step, the aluminum hydroxide obtained is weighed and packed (see Figure 5 ).

Embodiment 3

[0046] If 1kg of flake-shaped aluminum hydroxide powder is prepared, the proportions of ingredients in the preparation formula are as follows:

[0047] The aluminum hydroxide powder obtained by 1kg kind of method, 0.5 liters of isopropanol, 2 liters of water, the specific preparation process is as follows:

[0048] In the first step, 1 kg of aluminum hydroxide powder is added to a 4-liter hydrothermal reaction kettle, and 2.5 liters of isopropanol and water mixture are added, and stirred evenly.

[0049] In the second step, heat the reactor to 140° C., and heat-treat for 12 hours under stirring conditions.

[0050] The third step is to cool down to room temperature naturally under reduced pressure, and filter through a filter cloth to form a filter cake.

[0051] In the fourth step, the filter cake is beaten and spray-dried to obtain aluminum hydroxide powder.

[0052] The fifth step is to weigh and pack the obtained aluminum hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com