Waste concrete on-site reproduction machine for road deck and operation method of waste concrete on-site reproduction machine

A waste concrete and recycling machine technology, applied in the removal of solid waste and other directions, can solve the problems of low utilization rate of old materials, affecting driving safety, stability and comfort, destroying the coordination between the road and the surrounding environment, etc., to achieve work efficiency. High, good crushing effect, high degree of mechanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

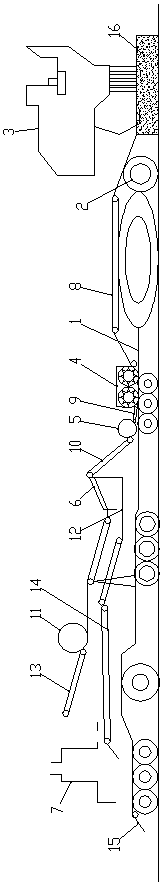

[0026] Such as figure 1 As shown, the waste and old concrete recycling machine for road surface layer of the present invention includes a vehicle frame 1, which can be a multi-joint connection type vehicle frame, so as to facilitate road turning and easy assembly. A power locomotive is provided at the front end, a number of wheels 2 are provided at the bottom of the frame 1, and a primary crushing device 3, a secondary crushing device 4, a cement mortar removal device 5, a fine vibrating screen 6, and a set Material collection system and stirring device 7, the material output port of the primary crushing device 3 is connected with the material input port of the secondary crushing device 4 through the first belt conveyor 8, and the material output port of the secondary crushing device 4 is conveyed by the second belt The machine 9 is connected with the material input port of the cement mortar removal device 5, the material output port of the cement mortar removal device 5 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com