Method for preparing silicon dioxide-coated magnetic microspheres

A technology of magnetic microspheres and silicon dioxide, applied in the direction of silicon dioxide, silicon oxide, magnetic materials, etc., can solve problems such as long reaction time, and achieve the effects of simple operation process, high magnetic content, surface modification and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

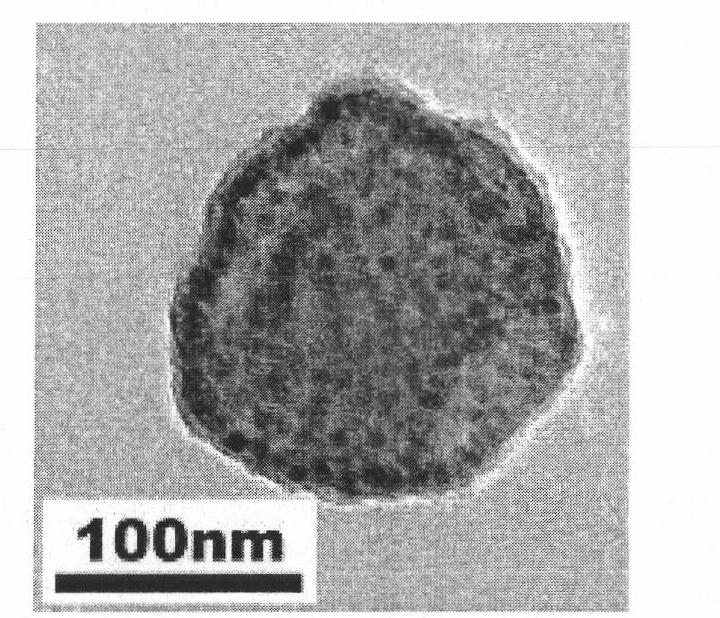

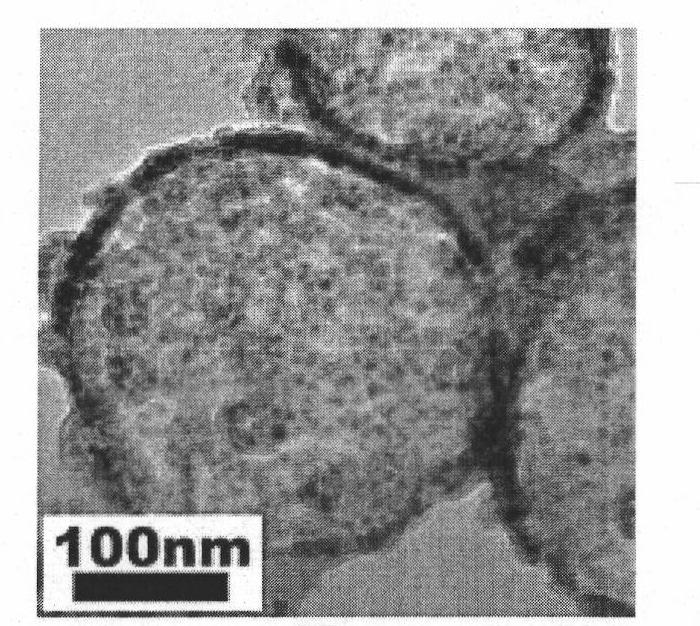

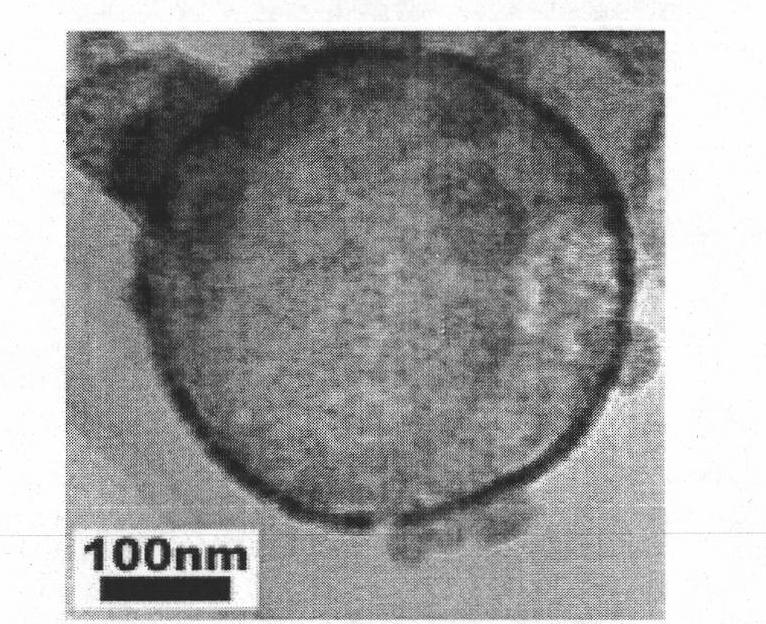

Image

Examples

Embodiment 1

[0029] 1. Take 0.811g of ferric chloride and 4.5625g of sodium oleate, disperse them in a mixed solution containing 35mL of n-hexane, 15mL of deionized water and 20mL of absolute ethanol, and stir at 70°C for 4h. Wash with deionized water three times, separate and collect the oil-soluble solution in the upper layer, and dry in an oven for 24 hours to obtain iron oleate, which is set aside.

[0030] 2. Take 5mmol iron oleate and 3.24mL oleic acid, disperse in 30mL 1-octadecene solution, in N 2 Under a protective atmosphere, the temperature was raised to 320° C., and the reaction was carried out for 30 minutes. That is, the oil-soluble ferroferric oxide magnetic nanoparticles are obtained. After the reaction is completed, the reaction product is cooled to room temperature, precipitated with absolute ethanol, and centrifuged several times, and finally dispersed in n-hexane to obtain an oil-soluble magnetic particle dispersion. The concentration of ferric iron tetroxide magnetic...

Embodiment 2

[0034] 1. Take 0.811g of ferric chloride and 4.5625g of sodium oleate, disperse them in a mixed solution containing 35mL of n-hexane, 15mL of deionized water and 20mL of absolute ethanol, and stir at 70°C for 4h. Wash with deionized water three times, separate and collect the oil-soluble solution in the upper layer, and dry in an oven for 24 hours to obtain iron oleate, which is set aside.

[0035] 2. Take 5mmol iron oleate and 3.24mL oleic acid, disperse in 30mL 1-octadecene solution, raise the temperature to 320°C under N2 protective atmosphere, and react for 30min. That is, the oil-soluble ferroferric oxide magnetic nanoparticles are obtained. After the reaction is completed, the reaction product is cooled to room temperature, precipitated with absolute ethanol, and centrifuged several times, and finally dispersed in n-hexane to obtain an oil-soluble magnetic particle dispersion. The concentration of ferric iron tetroxide magnetic nanoparticles is 15 mg / mL.

[0036] 3. Ta...

Embodiment 3

[0039] 1. Take 0.811g of ferric chloride and 4.5625g of sodium oleate, disperse them in a mixed solution containing 35mL of n-hexane, 15mL of deionized water and 20mL of absolute ethanol, and stir at 70°C for 4h. Wash with deionized water three times, separate and collect the oil-soluble solution in the upper layer, and dry in an oven for 24 hours to obtain iron oleate, which is set aside.

[0040] 2. Take 5mmol iron oleate and 3.24mL oleic acid, disperse in 30mL 1-octadecene solution, in N 2 Under a protective atmosphere, the temperature was raised to 320° C., and the reaction was carried out for 30 minutes. That is, the oil-soluble ferroferric oxide magnetic nanoparticles are obtained. After the reaction is completed, the reaction product is cooled to room temperature, precipitated with absolute ethanol, and centrifuged several times, and finally dispersed in n-hexane to obtain an oil-soluble magnetic particle dispersion. The concentration of ferric iron tetroxide magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com