Controllable emulsifying preparation method of PLGA micro-nano carriers of different scales

A PLGA, micro-nano technology, applied in the directions of non-active ingredients medical preparations, pharmaceutical formulas, emulsion delivery, etc., can solve the problems of inconsistency, difference in preparation technology, and unfavorable conversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

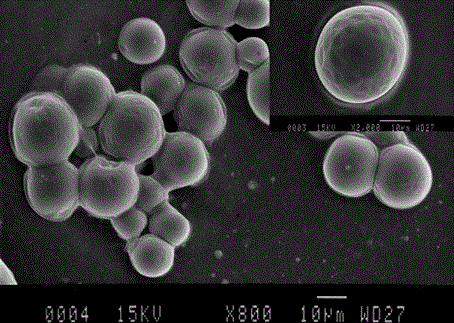

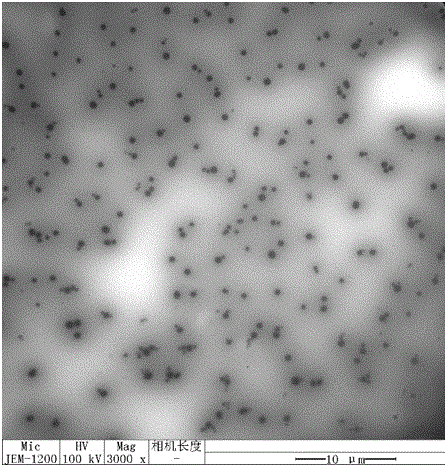

Image

Examples

Embodiment 1

[0018] Weigh 60 mg of PLGA (LA / GA=75 / 25, Mw=40 K) and dissolve it in 10 mL of ethyl acetate as the oil phase. Tween 80 and Span 80 are surfactants with HLB value of 12.5, mixed with oil phase. The mixture was added dropwise into 0.5% (w / v) hydroxyethylcellulose deionized aqueous solution with a syringe, stirred continuously at 1000 rpm, and reacted for 10 min. The total volume of the emulsion was fixed at 32 mL, where oil phase:water phase:surfactant=1.5:30:0.5 (v / v). Ethyl acetate was removed by rotating the emulsion under reduced pressure at room temperature, filtered to obtain a solid, washed three times with deionized water, and freeze-dried to obtain PLGA microcarriers. The average particle size is 150±5.6 μm.

Embodiment 2

[0020] Weigh 60 mg of PLGA (LA / GA=50 / 50, Mw=38 K) and dissolve it in 10 mL of ethyl acetate as the oil phase. Tween 80 and Span 80 are surfactants with an HLB value of 14, which are mixed with the oil phase. The mixture was added dropwise into 0.5% (w / v) hydroxyethylcellulose deionized aqueous solution with a syringe, stirred continuously at 1000 rpm, and reacted for 10 min. The total volume of the emulsion was fixed at 32 mL, where oil phase:water phase:surfactant=1.75:30:0.25 (v / v). Ethyl acetate was removed by rotating the emulsion at room temperature under reduced pressure, and the solid was obtained by filtration. The filter residue was washed three times with deionized water, and lyophilized to obtain PLGA microcarriers. The average particle size is 225±6.7 μm.

Embodiment 3

[0022] Weigh 10 mg of PLGA (LA / GA=75 / 25, Mw=40 K) and dissolve it in 10 mL of ethyl acetate as the oil phase. Tween 80 and Span 80 are surfactants with HLB value of 13, mixed with oil phase. The mixture was added dropwise into 0.1% (w / v) hydroxyethylcellulose deionized aqueous solution with a syringe, and stirred to form a primary emulsion. The obtained colostrum was ultrasonically mixed, the ultrasonic power was 200 W, the time was 180, 2 s on and 2 s off. The total mass of the emulsion is fixed at 12 g, where oil phase: water phase: surfactant = 1.75: 10: 0.25 (m / m). Ethyl acetate was removed by rotating the emulsion at room temperature under reduced pressure, centrifuged to obtain a solid, washed three times with deionized water, each time for 10 min, and the rotation speed was 8500 rpm, and freeze-dried to obtain PLGA nanocarriers. The average particle size is 330±4.3 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com