Material for hollow nano organosilicon sphere and preparation method of material

A technology of nano-organosilicon and hollow spheres, applied in chemical instruments and methods, inorganic chemistry, and other chemical processes, can solve problems in the field of difficult oil and gas adsorption, and achieve excellent hydrophobic performance, variable wall properties, and good oil and gas adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

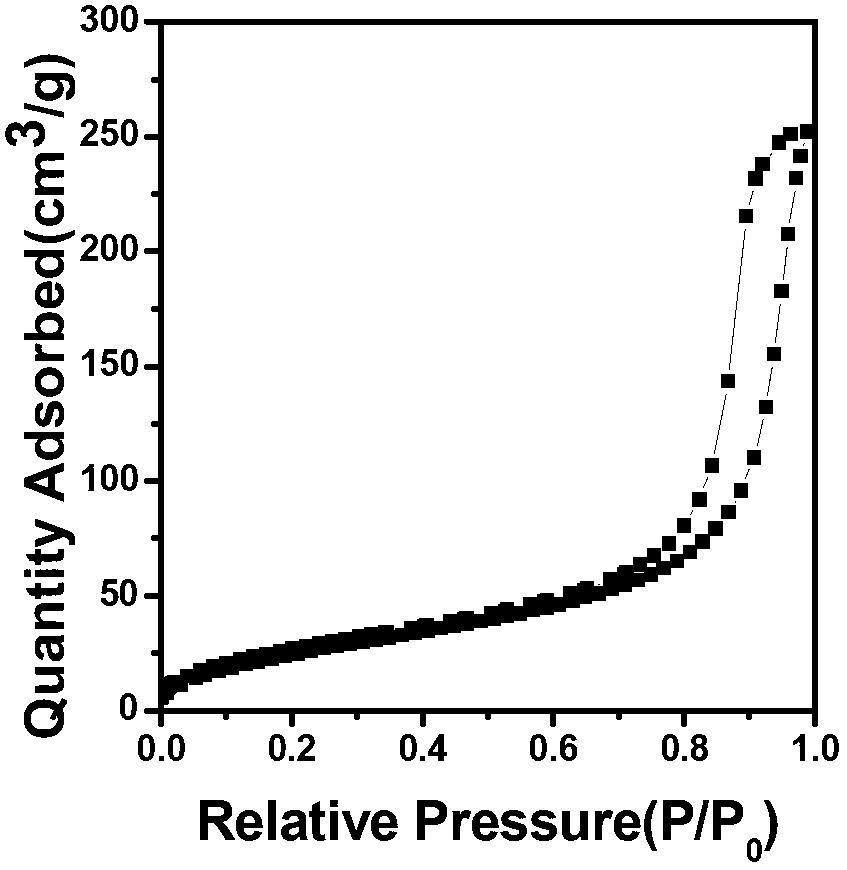

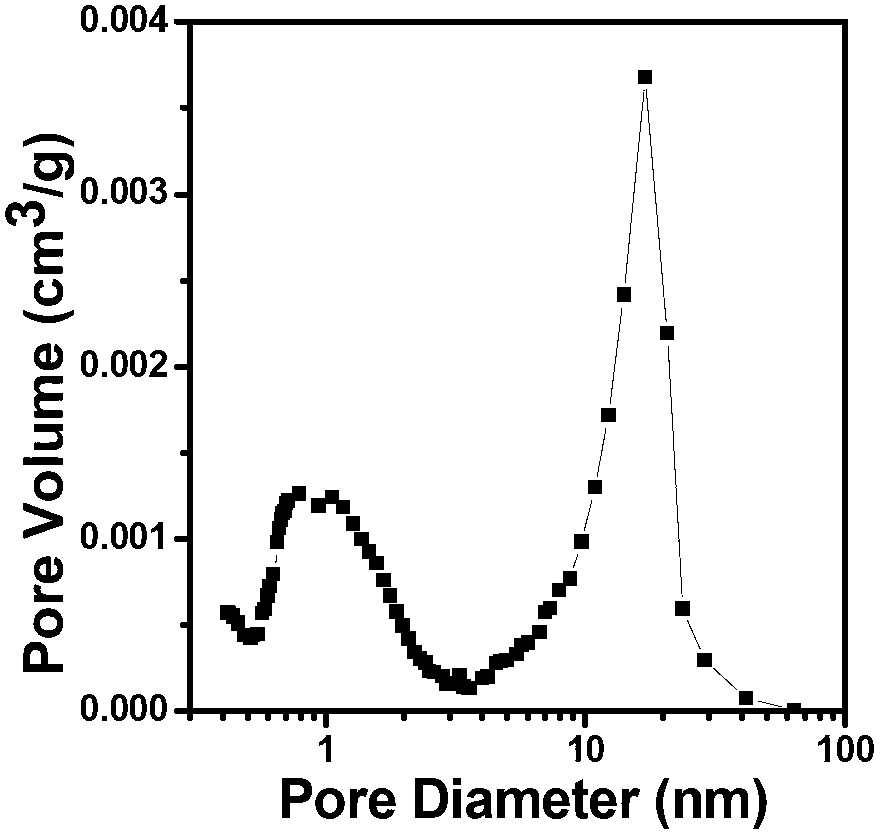

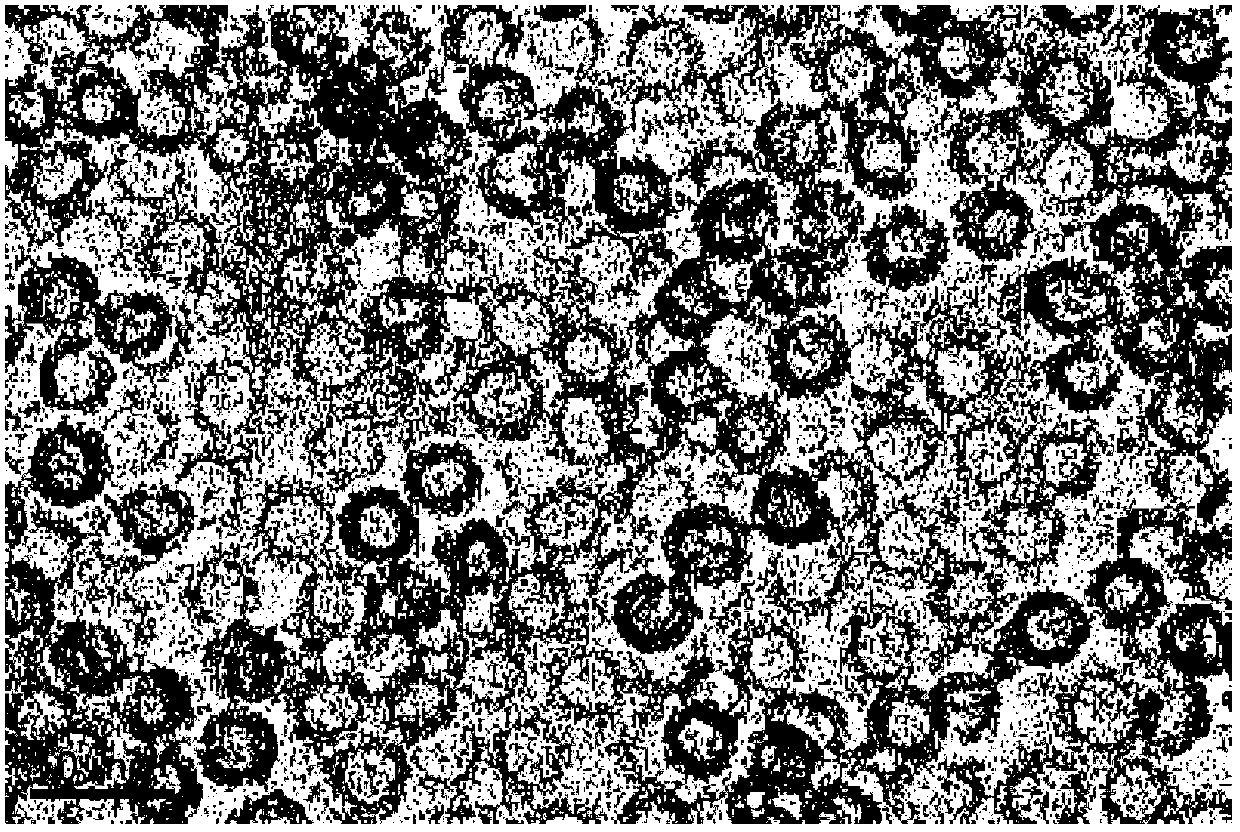

[0028] Dissolve 0.5 g of F108 (nonionic surfactant F108) and 1.0 g of TMB (mesitylene) in 30 mL of 2 mol×L under stirring at 25 °C in a constant temperature water bath -1 In the hydrochloric acid system, after stirring for more than 6 hours to form a milky white emulsion liquid homogeneous system, add 0.9 g TEOS (tetraethyl orthosilicate) and 0.171 g BTSE (1,2-bis (triethoxysilyl) ethane) After stirring for 6 hours, 0.5 g of DMDMOS (dimethyldimethoxysilane) was added, and constant temperature stirring was continued for 48 hours. The resulting liquid was poured into a dialysis bag with a molecular weight cut-off of 14,000, put into distilled water and repeatedly replaced with distilled water (once every 6 hours) and dialyzed for at least two days. After dialysis, the solution from which hydrochloric acid or other inorganic ions were removed was dried in an oven at 100 °C, and the resulting solid was refluxed in ethanol for 12 hours to remove the surfactant to obtain a nano-orga...

Embodiment 2

[0031] Dissolve 2.0 g F108 and 1.0 g TMB in 30 mL 2 mol×L under stirring at 25 °C in a constant temperature water bath -1 In the hydrochloric acid system, after stirring for more than 6 hours to form a milky white emulsion liquid homogeneous system, add 0.9 g TEOS and 0.171 g BTSE, add 0.5 g DMDMOS after stirring for 6 hours, and continue stirring at constant temperature for 48 hours. The resulting liquid was poured into a dialysis bag with a molecular weight cut-off of 14,000, put into distilled water and repeatedly replaced with distilled water (once every 6 hours) and dialyzed for at least two days. After dialysis, the solution from which hydrochloric acid or other inorganic ions were removed was dried in an oven at 100 °C, and the resulting solid was refluxed in ethanol for 12 hours to remove the surfactant to obtain a nano-organic silicon hollow sphere material.

Embodiment 3

[0033]Dissolve 1.0 g F108 and 1.0 g TMB in 17 mL 2 mol×L under stirring at 25 °C in a constant temperature water bath -1 In the hydrochloric acid system, after stirring for more than 6 hours to form a milky white emulsion liquid homogeneous system, add 0.9 g TEOS and 0.171 g BTSE, add 0.5 g DMDMOS after stirring for 6 hours, and continue stirring at constant temperature for 48 hours. The resulting liquid was poured into a dialysis bag with a molecular weight cut-off of 14,000, put into distilled water and repeatedly replaced with distilled water (once every 6 hours) and dialyzed for at least two days. After dialysis, the solution from which hydrochloric acid or other inorganic ions were removed was dried in an oven at 100 °C, and the resulting solid was refluxed in ethanol for 12 hours to remove the surfactant to obtain a nano-organic silicon hollow sphere material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Acid concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com