Efficient circulating fluidized bed grinding equipment and application method thereof

A technology of circulating fluidized bed and equipment, which is applied in swirl devices, devices whose axial direction can be reversed, and grain processing, etc., which can solve the problems of large equipment investment, high energy consumption, and low cost, and achieve shortening Process flow, improved grinding efficiency, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

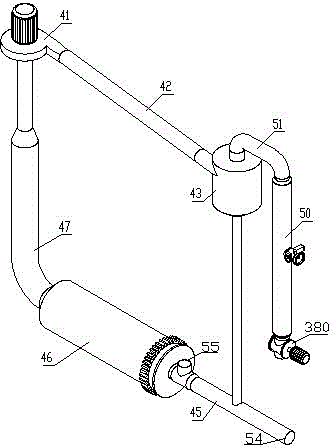

[0020] Example 1: Efficient circulating fluidized bed grinding equipment

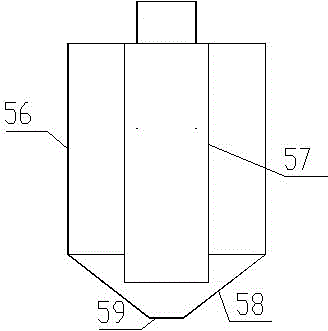

[0021] see figure 1 and figure 2 , consisting of fan 41, positive pressure circulation pipe Ⅰ 42, cyclone dust collector 43, negative pressure circulation pipe 45, mill 46, rear section of negative pressure circulation pipe 47, positive pressure circulation pipe Ⅱ 51, bag filter branch, cyclone dust removal The device 43 is used to realize the separation of qualified fine powder and coarse powder. There are three interfaces on the cyclone dust collector 43. The air inlet is the inlet of fluidized material, the ash discharge port 59 is the outlet of coarse powder, and the exhaust port is the qualified fluidized fine powder. Powder outlet, the head end of the negative pressure circulation pipe is the air inlet 54, and the tail end is the air outlet. The ratio of the diameter of the cylinder body of the cyclone dust collector to the height of the cone is 2.5. The separation cylinder 57 of the vortex air...

Embodiment 2

[0022] Embodiment 2: the use method of efficient circulating fluidized bed grinding equipment

[0023] Follow these steps:

[0024] S1. Start up: start the mill, start the fan, so that the air flow flows at a high speed in the circulation channel;

[0025] S2. Feeding: Start the feeding device to add materials into the high-efficiency circulating fluidized bed grinding equipment, and adjust the feeding amount to match the production capacity of the equipment;

[0026] S3. Operation process and adjustment control:

[0027] S301. Primary crushing: after the mill crushes the large-diameter materials initially, the small-particle materials produced form a fluidized state under the action of high-speed airflow;

[0028] S302. Control the particle size of the material entering the fan: After the fluidized material enters the rear section of the negative pressure circulation pipe, because the diameter of the inlet end of the rear section of the negative pressure circulation pipe is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com