Preparation process for non-cleaning carboxyl polystyrene microspheres

A technology for preparing polystyrene microspheres, which is applied in the field of medical testing, can solve problems such as variable polymerization rates, uncontrollable carboxyl content, and uneven distribution of carboxyl groups on the surface, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation technology of the carboxyl polystyrene microsphere of no-cleaning of the present invention comprises the following steps:

[0031] The first step: remove the polymerization inhibitor in styrene with sodium hydroxide solution.

[0032] Step 2: Preparation of the external water phase: Weigh the emulsifier and place it in a 1L three-necked flask, add 400ml of HEPES-NaOH buffer solution (pH=8.0), stir and dissolve, so that the concentration of the emulsifier in the water phase is lower than 1 The critical micelle concentration of / 2; nitrogen or argon gas is passed into the system, and the temperature is raised to 80-90°C at the same time, and the emulsifier is sodium dodecyl sulfate (SDS) and / or sodium dodecylbenzenesulfonate (SDBS).

[0033] Step 3: In the case of high-speed stirring, pour one of acrylic acid, methacrylic acid, and ethyl acrylate (two or three) at one time; the molar ratio of it to styrene is 0.05:1~0.5: 1; Stir for 10-30min, the l...

Embodiment 2~ Embodiment 6

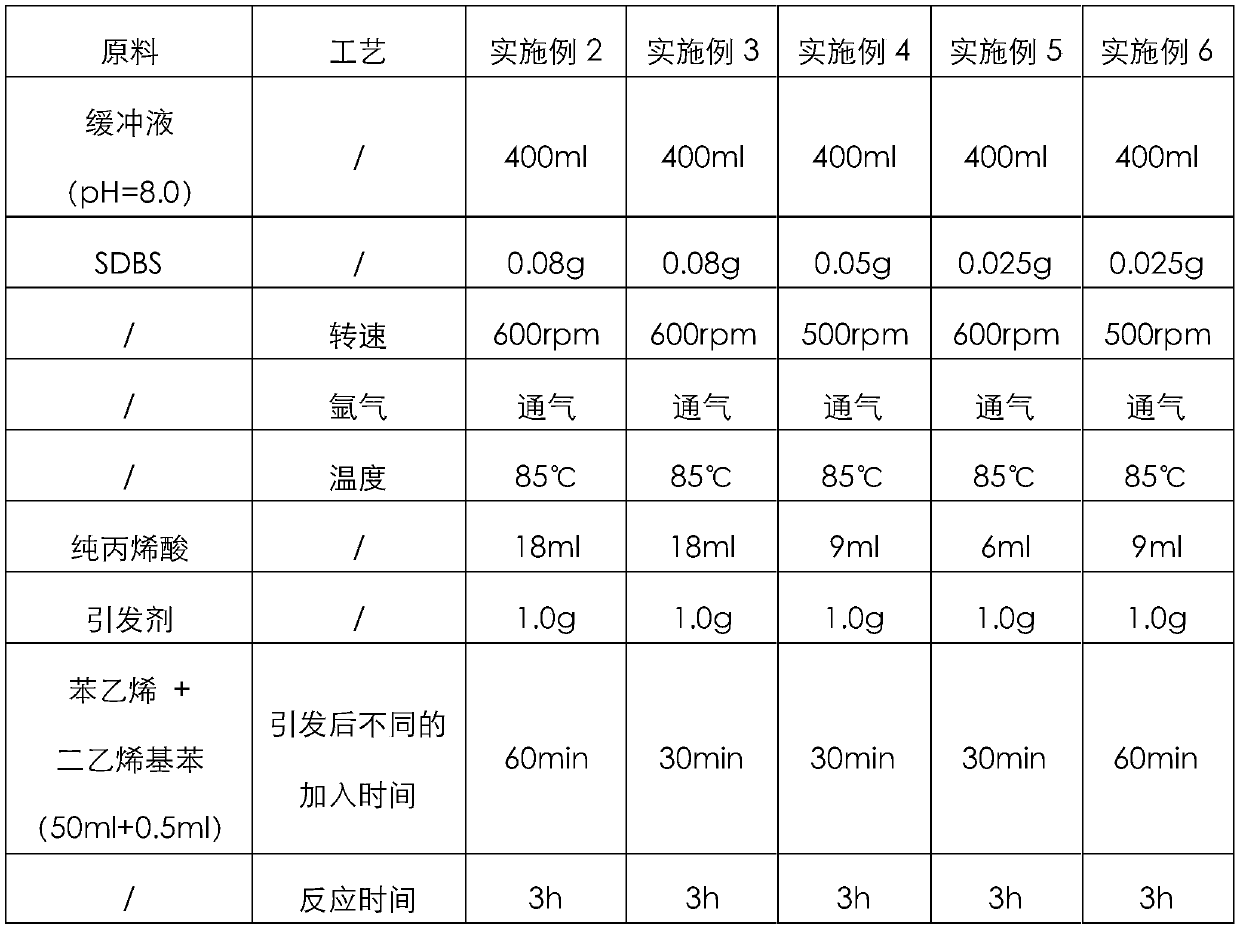

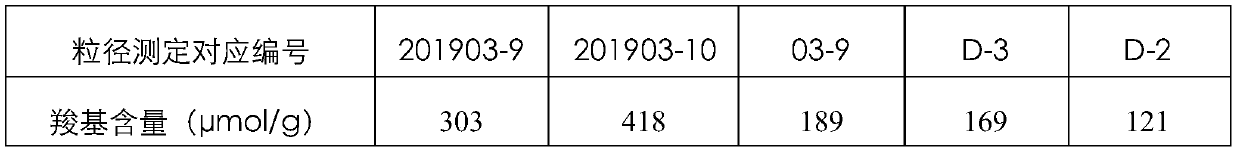

[0040] Embodiment 2~Example 6 all prepare the no-cleaning carboxyl polystyrene microsphere according to the technique of Example 1, and the raw material, amount, concentration and reaction conditions specifically involved are as shown in Table 1:

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com