Method for producing phosphoric acid and jointly producing cement and synthetic ammonia by using phosphorus ores, limestone and silica

A technology of limestone and phosphate rock, applied in the fields of comprehensive utilization of resources and chemical production, can solve problems such as phosphoric acid-free co-production of cement, synthetic ammonia, etc., and achieve the goal of eliminating environmental pollution by tail gas emissions, improving overall value, and high utilization of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

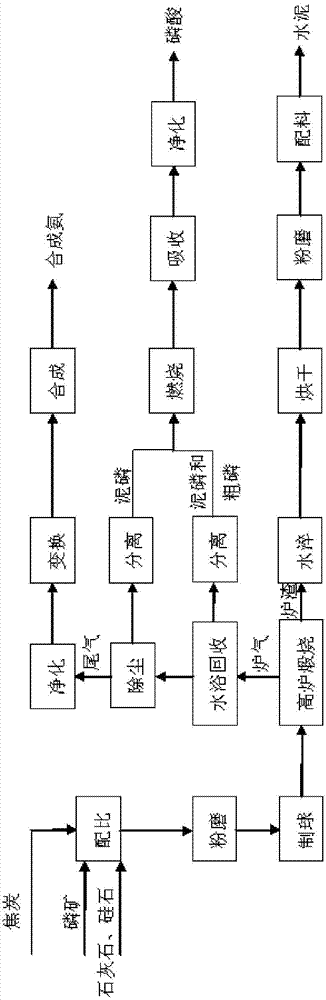

Image

Examples

Embodiment 1

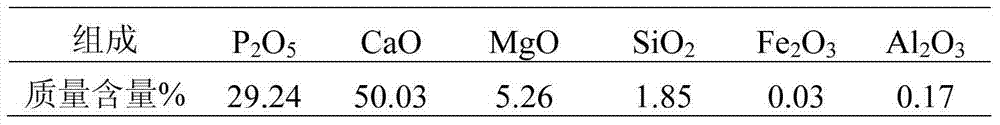

[0051] Raw material: medium and low grade phosphate rock, collection location: Guizhou Weng'an Mining Industry

[0052] The main chemical composition of medium and low grade phosphate rock is shown in the table below:

[0053]

[0054] A method for producing phosphoric acid co-production cement and synthetic ammonia with phosphate rock, limestone and silica, comprising steps as follows:

[0055] (1) Preparation of phosphoric acid

[0056] The medium and low-grade phosphate rock, silica, limestone and coke are mixed according to the mass ratio of 1:0.5:1.2:1.6. After grinding, pass through a 100-mesh sieve, add water to make a 5mm spherical block, and calcinate in a blast furnace at a temperature of 1150°C for 60 Minutes, solid slag and furnace gas are obtained. The furnace gas is cooled by a water bath to recover crude phosphorus and sludge phosphorus. The crude phosphorus and sludge phosphorus are recovered by cooling in a water bath. The water temperature is 20°C, and t...

Embodiment 2

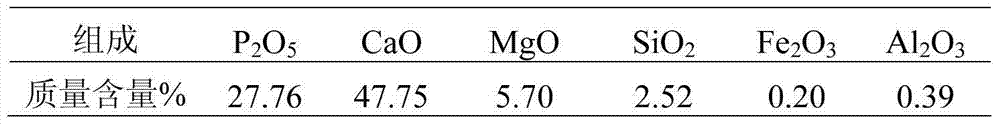

[0064] Raw material: medium and low-grade phosphate rock, collection location: Jinde Mining, Guizhou

[0065] The main chemical composition of medium and low grade phosphate rock is shown in the table below:

[0066]

[0067] A method for producing phosphoric acid co-production cement and synthetic ammonia with phosphate rock, limestone and silica, comprising steps as follows:

[0068] (1) Preparation of phosphoric acid

[0069] The medium and low-grade phosphate rock, silica, limestone and coke are mixed according to the mass ratio of 1:0.4:0.6:0.9. After grinding, pass through a 100-mesh sieve, add water to make a spherical block of 8mm, and calcinate it in a blast furnace at a temperature of 1300°C for 40 Minutes, solid slag and furnace gas are obtained. The furnace gas is cooled by a water bath to recover crude phosphorus and sludge phosphorus. The crude phosphorus and sludge phosphorus are recovered by cooling in a water bath. The gas is then dedusted to recover the ...

Embodiment 3

[0077] Raw material: medium and low-grade phosphate rock, collection location: Yunnan Zhanyideze phosphate rock

[0078] The main chemical composition of medium and low grade phosphate rock is shown in the table below:

[0079]

[0080] A method for producing phosphoric acid co-production cement and synthetic ammonia with phosphate rock, limestone and silica, comprising steps as follows:

[0081] (1) Preparation of phosphoric acid

[0082] The medium and low-grade phosphate rock, silica, limestone and coke are mixed according to the mass ratio of 1:0.2:1.5:1.8. After grinding, pass through a 150-mesh sieve, add water to make a 15mm spherical block, and calcinate in a blast furnace at a temperature of 1450°C for 30 Minutes, solid slag and furnace gas are obtained. The furnace gas is cooled by a water bath to recover crude phosphorus and sludge phosphorus. The crude phosphorus and sludge phosphorus are recovered by cooling in a water bath. The gas is then dedusted to recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com