A kind of electrolyte solution and lithium ion secondary battery

A secondary battery, lithium ion technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems that do not involve the application of cyclic phosphoric anhydride, and achieve improved cycle performance, good thermal stability, and reduced gas production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

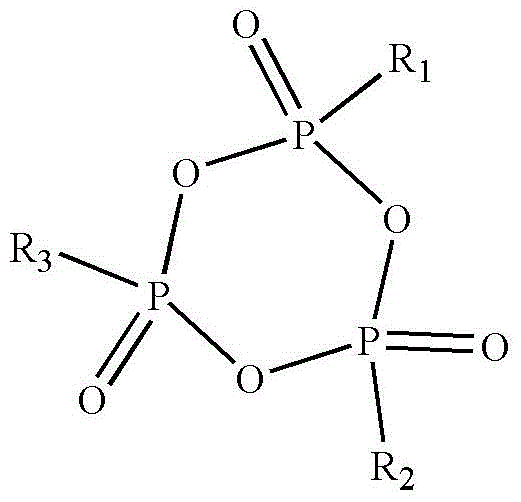

[0032] with LiPF 6 It is an electrolyte lithium salt, EC / EMC is an aprotic organic solvent, and 1-perfluoropropyl phosphoric anhydride (FPACA) is used as an additive, where EC:EMC=1:2, LiPF 6 The mass fraction is 12%, and the FPACA mass fraction is 0.1% (the above ratios are all mass ratios), in a dry glove box filled with high-purity argon (H 2 O2 6, stirred evenly, transferred to a 1L fluoride bottle through a funnel, sealed with aluminum plastic film, and then added an appropriate amount of electrolyte to Li / LiNi 0.5 mn 1.5 o 4 Coin Cell and Graphite / LiNi 0.5 mn 1.5 o 4 Charge and discharge test in full battery.

Embodiment 2

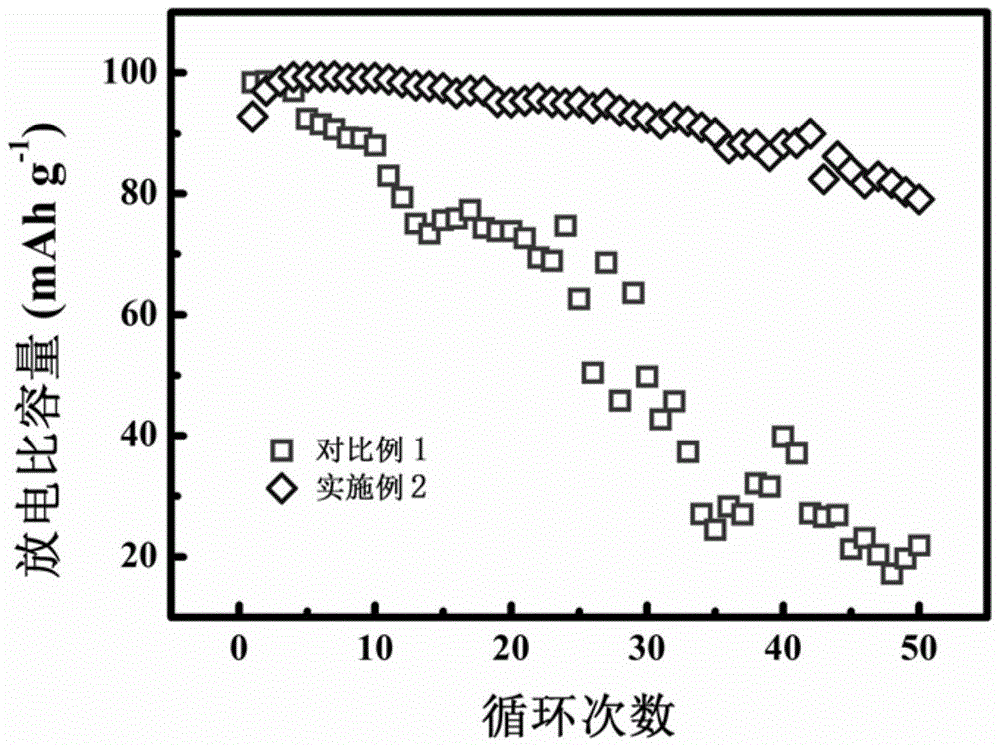

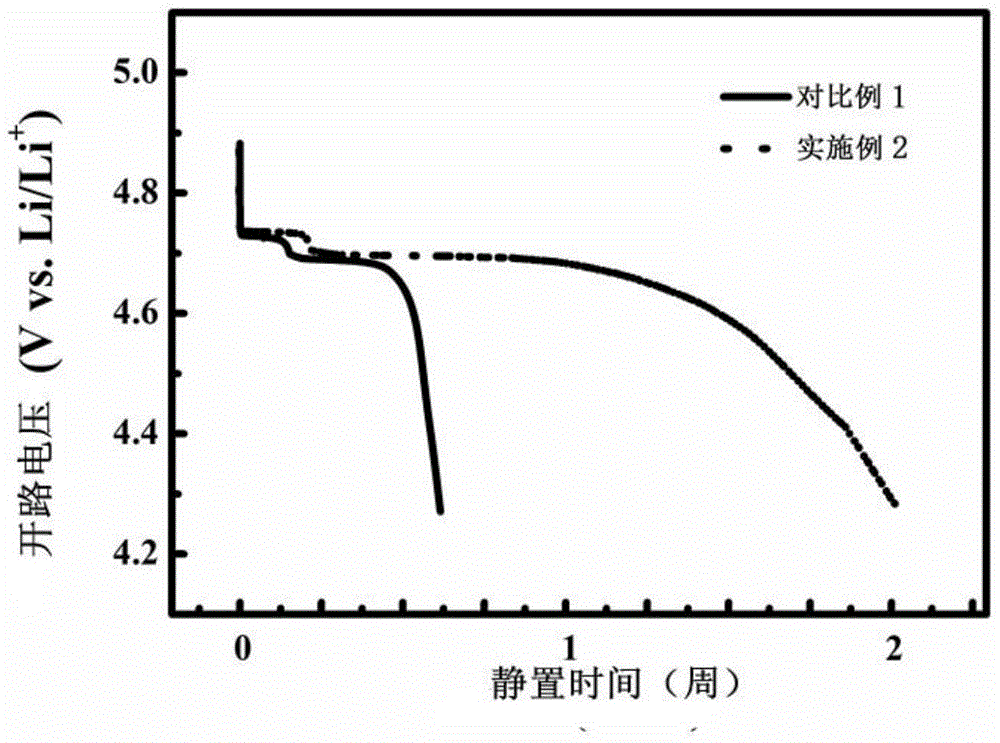

[0034] with LiPF 6 It is an electrolyte lithium salt, EC / EMC is an aprotic organic solvent, and FPACA is used as an additive, where EC:EMC=1:2, LiPF 6 The mass fraction is 12%, and the FPACA mass fraction is 0.5% (the above ratios are all mass ratios), in a dry glove box filled with high-purity argon (H 2 O2 6 , stirred evenly, transferred to a 1L fluoride bottle through a funnel, sealed with aluminum plastic film, and then added an appropriate amount of electrolyte to Li / LiNi 0.5 mn 1.5 o 4 Coin Cell and Graphite / LiNi 0.5 mn 1.5 o 4 Charge and discharge test in full battery.

Embodiment 3

[0036] with LiPF 6 It is an electrolyte lithium salt, EC / EMC is an aprotic organic solvent, and FPACA is used as an additive, where EC:EMC=1:2, LiPF 6 The mass fraction is 12%, and the FPACA content is 2% (the above ratios are all mass ratios), in a dry glove box filled with high-purity argon (H 2 O2 6 , stirred evenly, transferred to a 1L fluoride bottle through a funnel, sealed with aluminum plastic film, and then added an appropriate amount of electrolyte to Li / LiNi 0.5 mn 1.5 o 4 Coin Cell and Graphite / LiNi 0.5 mn 1.5 o 4 Charge and discharge test in full battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com