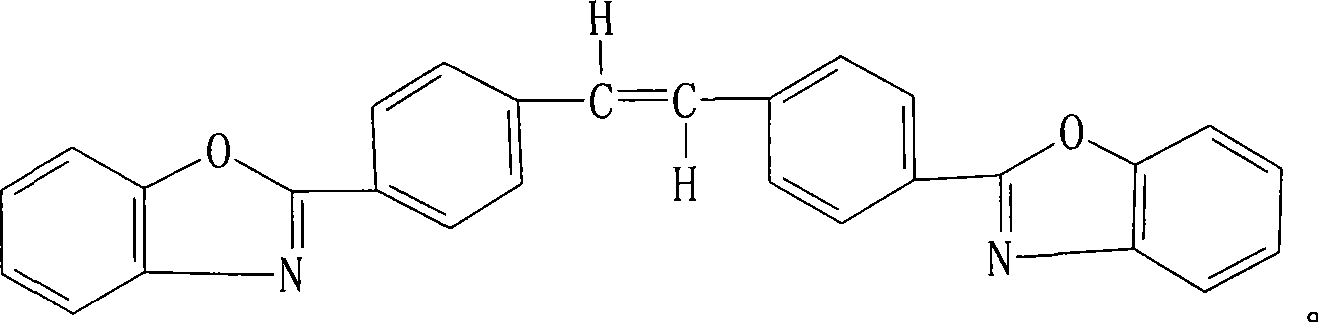

Method for preparing anti-ultraviolet ageing poly-p-phenylene-benzobisoxazole (PBO) fiber

A benzobisoxazole and anti-ultraviolet aging technology, which is applied in the fields of fiber chemical characteristics, spinning solution preparation, rayon manufacturing, etc., can solve the problems of affecting, restricting the application of PBO fibers, and reducing the mechanical properties of fibers, so as to improve the optical properties. Stabilize performance, improve photostability performance, improve the effect of UV resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Polymerize and spin by the method described in Comparative Example 1, the difference is that 0.1149g of anti-ultraviolet agent TM is added to the polymerization system, the fineness of the prepared fiber is 4.8dtex, the tensile strength is 3.3GPa, and the elongation at break The growth rate is 5.1%.

[0022] After the PBO fiber was irradiated with ultraviolet light for 100 hours, the strength retention rate was 65%.

Embodiment 2

[0024] Polymerize and spin by the method described in Comparative Example 1, the difference is that 0.5745g of anti-ultraviolet agent TM is added to the polymerization system, the fineness of the prepared fiber is 4.6dtex, the tensile strength is 3.4GPa, and the elongation at break The growth rate is 4.8%.

[0025] After the PBO fiber was irradiated with ultraviolet light for 100 hours, the strength retention rate was 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com