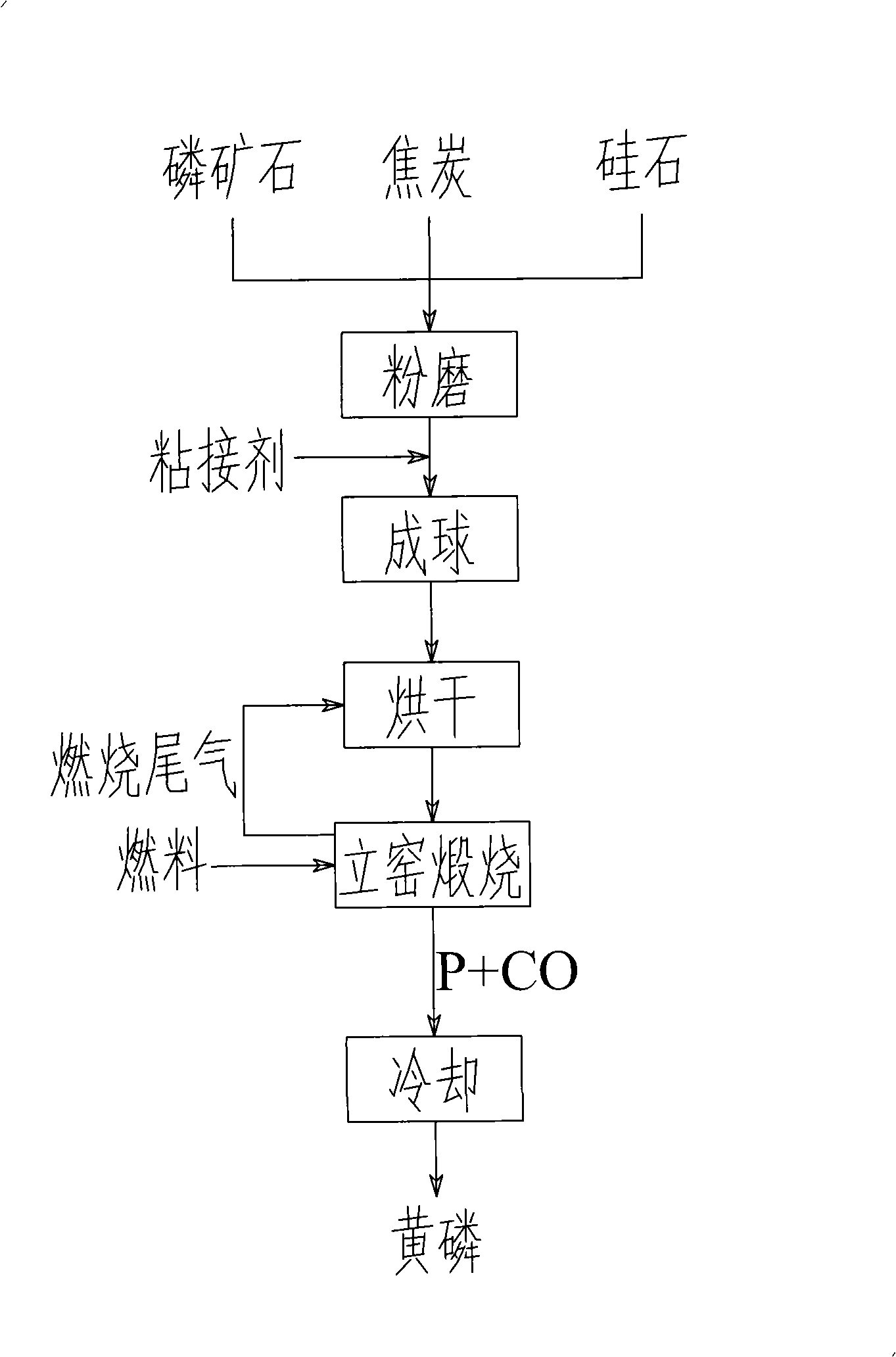

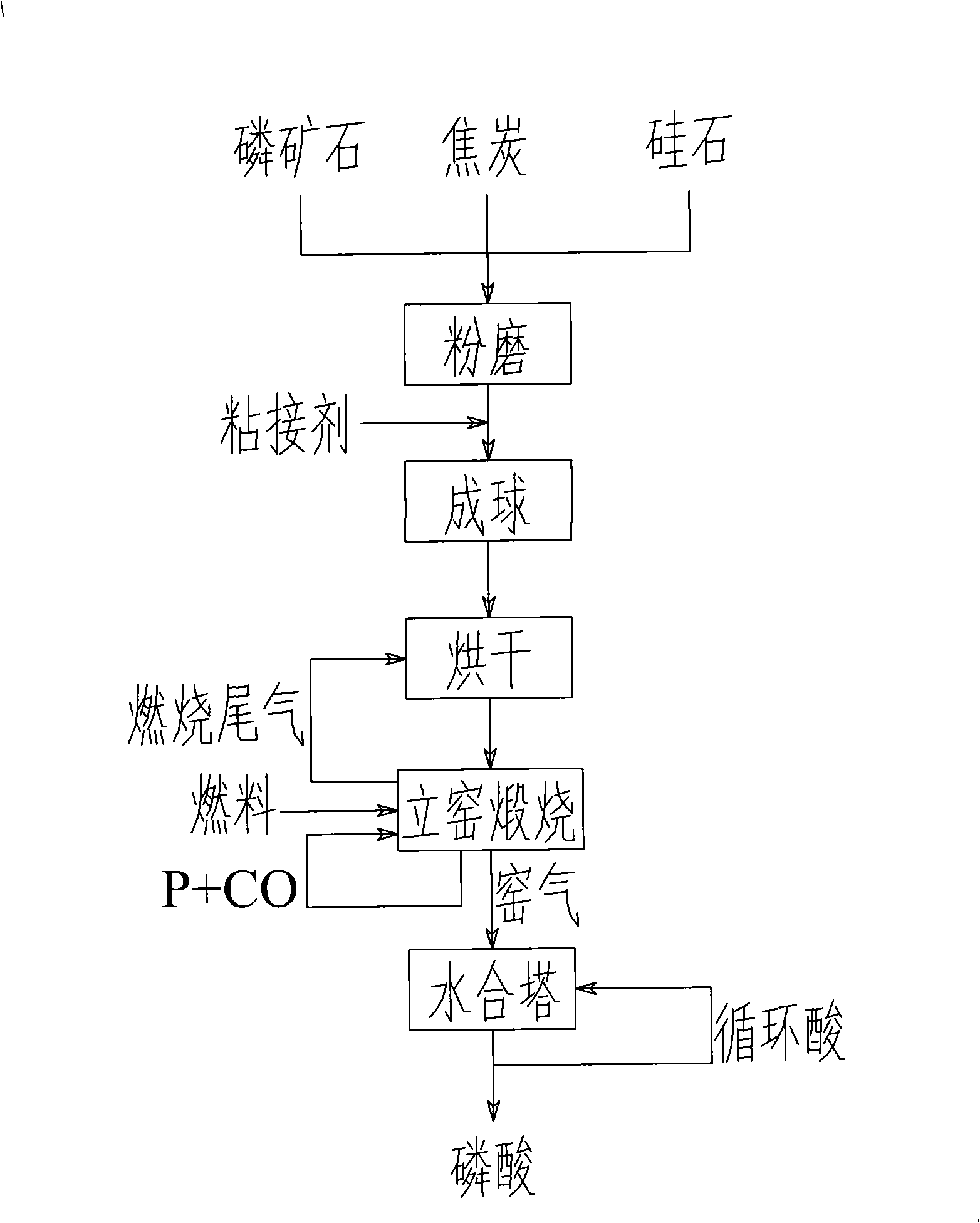

Method and equipment for preparing yellow phosphorus or phosphoric acid with vertical enclosed tobacco-partition kiln

A kiln and smoke isolation technology, applied in phosphoric acid, phosphorus oxyacid, chemical instruments and methods, etc., can solve the problems of high temperature and corrosion resistance requirements of green body protection materials, high chemical protection cost, and low thermal efficiency of tunnel kilns. To achieve the effect of saving energy consumption, reducing consumption, and reducing the generation of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

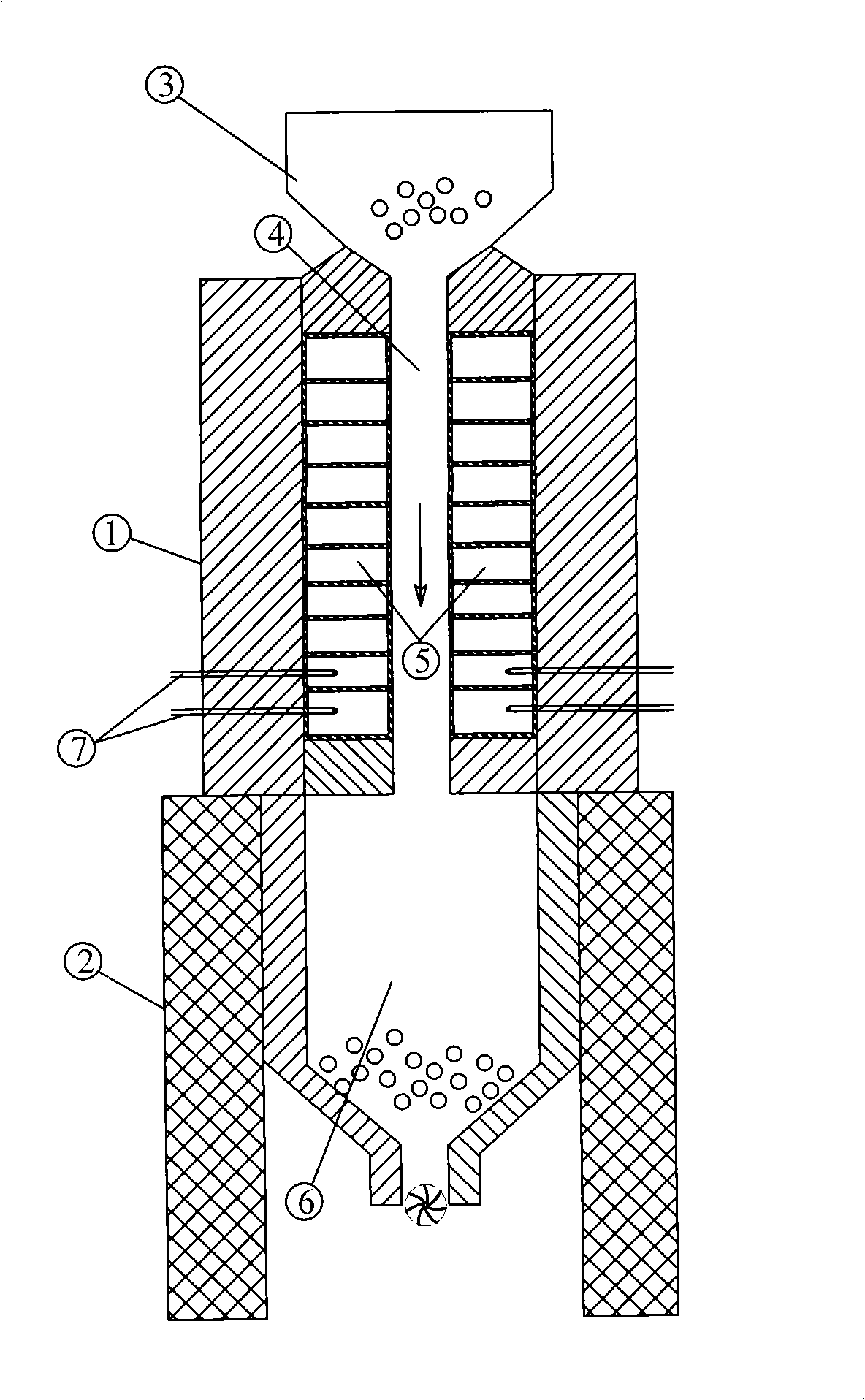

[0047] A pilot production line for a vertical airtight smoke-insulated kiln producing 3,000 tons of 85% phosphoric acid per year. The vertical airtight smoke-proof kiln is 4.5m long, 3.9m wide, and 20.0m high; the material channel is 1.4m long, 0.35m wide, and 4.9m high; the phosphorus combustion channel and fuel channel are 1.4m long, 0.24m wide, and 4.9m high , The heat transfer refractory material between each channel is 80mm thick, and the material is fused corundum brick; there are 3 material channels, 2 phosphorus combustion channels, and 2 fuel channels. Before heating up, close the unloading device, fill the cooling hopper and material channel in the kiln with waste residue, and then ignite and heat up. The pellets are transported to the top hopper of the kiln body, the unloading device is opened, and the pellets enter the material channel under the action of natural gravity through continuous discharge, and the temperature rises to the reaction temperature to generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com