Preparation method of catalyst for removing trace amounts of alkenes in reformate

A technology for reforming to generate oil and olefin catalysts, which is applied in the direction of reforming naphtha, molecular sieve catalysts, chemical instruments and methods, etc., to achieve the effects of low operating costs, uniform dispersion, and labor cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

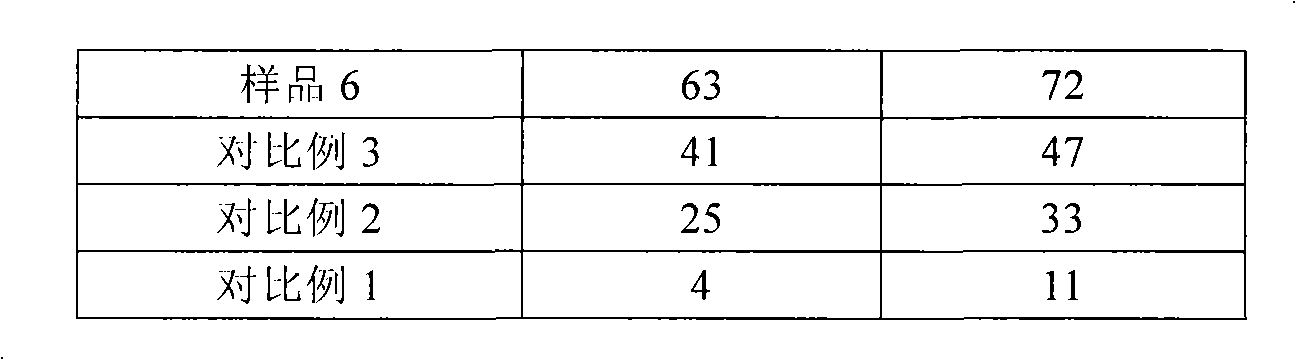

Embodiment 1

[0035] (1) Dissolve 75 grams of USY molecular sieves in 750ml of deionized water, heat up to 80°C under stirring, and add 3.01 grams of LaCl in turn 3 , 3.01 g CeCl 3 , 3.72 g (NH 4 ) 2 HPO 4 , continue to stir for 2 hours, filter and dry, and 18gAl 2 o 3 Mix evenly, add dilute nitric acid solution with a mass concentration of 3%, extrude the product into the form of a φ1.6 extrudate, dry at 110°C for 6 hours, and roast at 500°C for 4 hours in an air atmosphere to obtain La, Ce, and P-loaded Molecular sieve.

[0036] (2) 2.38 grams of MgCl 2 Dissolve in 150ml of deionized water, add 8ml of a solution containing cetyldimethylammonium chloride 30g / L to the above solution, and stir for 1 hour to obtain a highly dispersed solution of Mg.

[0037] (3) The molecular sieve obtained in step (1) was immersed in the solution obtained in step (2) for 12 hours, the product was dried at 110°C for 6 hours, and calcined at 500°C for 4 hours in an air atmosphere to obtain the finished ...

Embodiment 2

[0039](1) Dissolve 75 grams of USY molecular sieves in 750ml of deionized water, raise the temperature to 80°C under stirring, and add 4.51 grams of LaCl in turn 3 , 4.51 g CeCl 3 , 3.72 g (NH 4 ) 2 HPO 4 , continue to stir for 2 hours, filter and dry, and 16gAl 2 o 3 Mix evenly, add dilute nitric acid solution with a mass concentration of 3%, extrude the product into the form of a φ1.6 extrudate, dry at 110°C for 6 hours, and roast at 500°C for 4 hours in an air atmosphere to obtain La, Ce, and P-loaded Molecular sieve.

[0040] (2) 2.38 grams of MgCl 2 Dissolve in 150ml of deionized water, add 8ml of a solution containing cetyldimethylammonium chloride 30g / L to the above solution, and stir for 1 hour to obtain a highly dispersed solution of Mg.

[0041] (3) Immerse the molecular sieve obtained in step (1) in the solution obtained in step (2) for 12 hours, dry the product at 110°C for 6 hours, and roast at 500°C for 4 hours in an air atmosphere to obtain the finished c...

Embodiment 3

[0043] (1) Dissolve 75 grams of USY molecular sieves in 750ml of deionized water, raise the temperature to 80°C under stirring, and add 5.27 grams of LaCl in turn 3 , 5.27 g CeCl 3 , 3.72 g (NH 4 ) 2 HPO 4 , continue to stir for 2 hours, and filter and dry with 15gAl 2 o 3 Mix evenly, add dilute nitric acid solution with a mass concentration of 3%, extrude the product into the form of a φ1.6 extrudate, dry at 110°C for 6 hours, and roast at 500°C for 4 hours in an air atmosphere to obtain La, Ce, and P-loaded Molecular sieve.

[0044] (2) 2.38 grams of MgCl 2 Dissolve in 150ml of deionized water, add 8ml of a solution containing cetyldimethylammonium chloride 30g / L to the above solution, and stir for 1 hour to obtain a highly dispersed solution of Mg.

[0045] (3) The molecular sieve obtained in step (1) was immersed in the solution obtained in step (2) for 12 hours, the product was dried at 110°C for 6 hours, and calcined at 500°C for 4 hours in an air atmosphere to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com