Catalyst for toluene alkylation reaction, and preparation method thereof

A technology of toluene alkyl and catalyst, which is applied in the field of catalyst and its preparation, can solve the problems of low conversion rate of toluene, etc., and achieve the effects of prolonged reaction life, enhanced activity stability, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

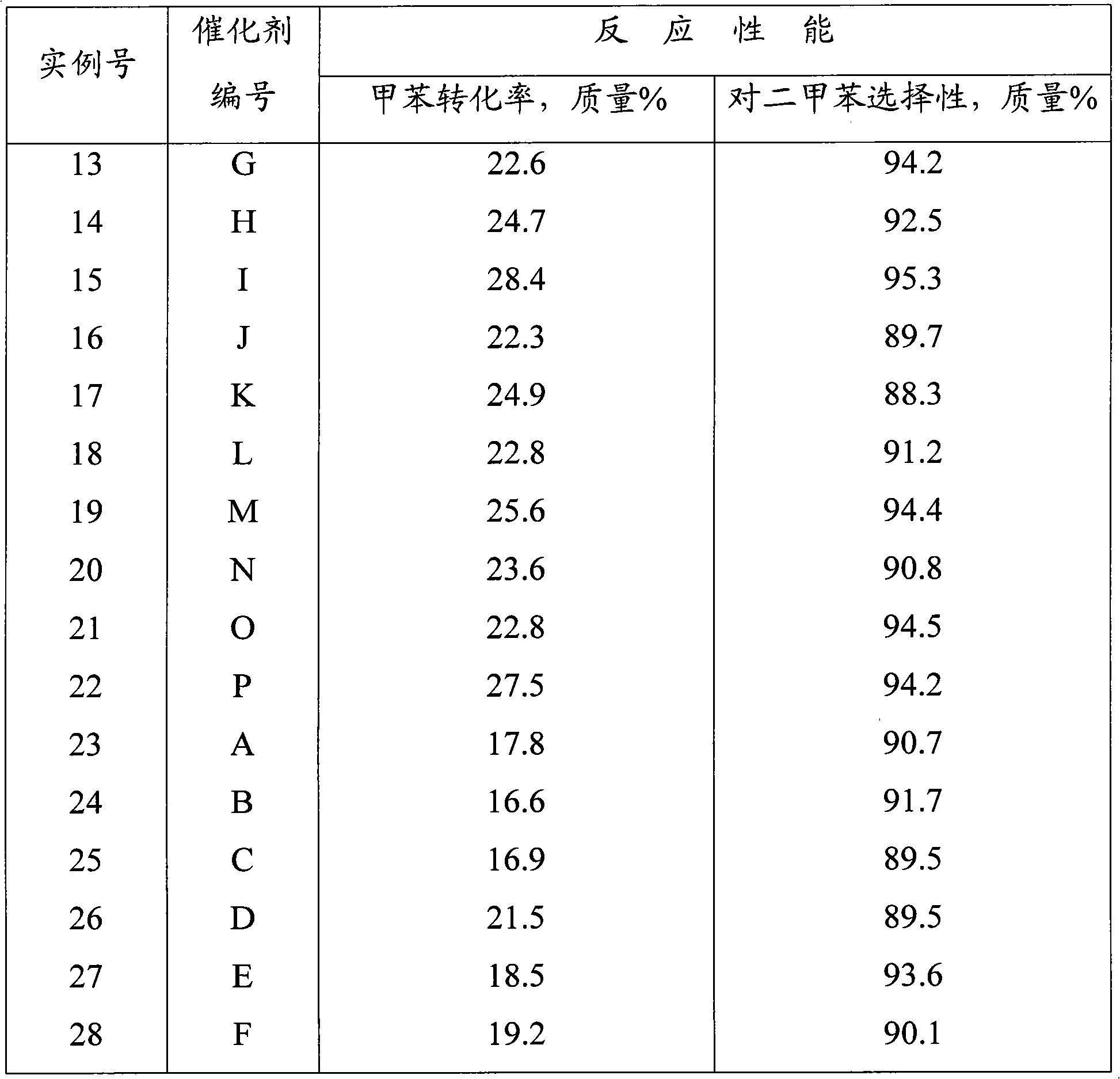

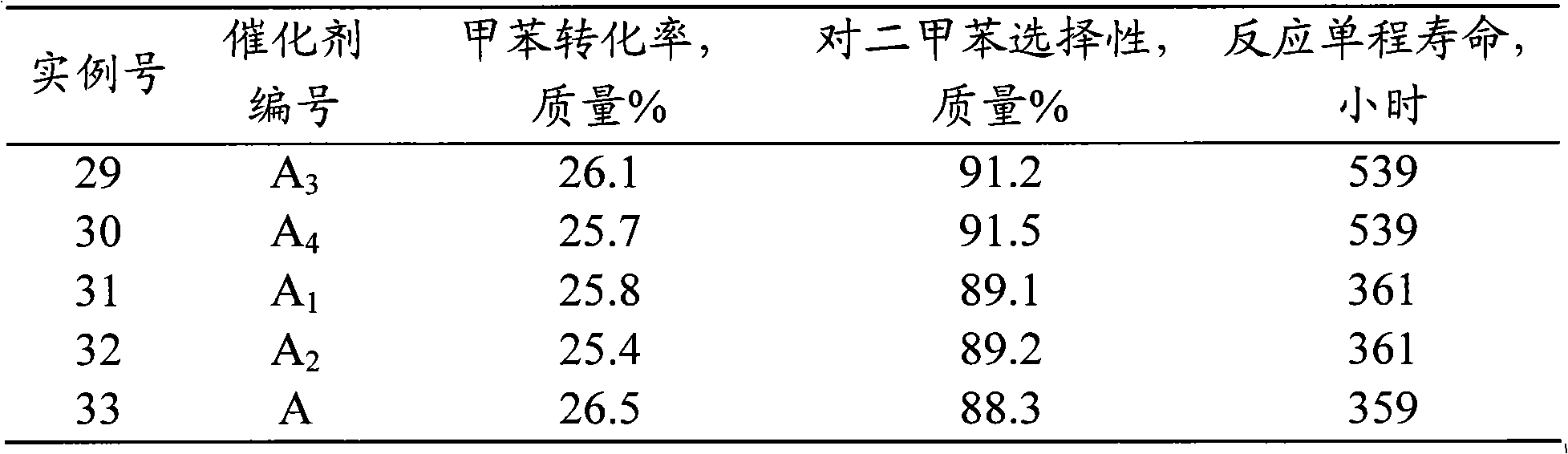

Examples

preparation example Construction

[0017] The preparation method of the catalyst provided by the invention comprises the steps of mixing the P-ZSM-5 / Silicalite-1 composite molecular sieve and the Silicalite-1 molecular sieve which are loaded with rare earth elements on the outer layer and forming them.

[0018] The preparation method of the preferred catalyst provided by the present invention includes uniformly mixing the P-ZSM-5 / Silicalite-1 composite molecular sieve, the Silicalite-1 molecular sieve and the precursor of the binder, which are loaded with rare earth elements on the outer layer, and then forming, drying and roasting.

[0019] The precursor of the binder is pseudo-boehmite or silica sol.

[0020] The preparation method of the P-ZSM-5 / Silicalite-1 composite molecular sieve of the outer layer loading rare earth elements comprises the following steps:

[0021] (1) impregnating the HZSM-5 molecular sieve with a phosphorus-containing compound solution, drying and roasting to obtain P-ZSM-5,

[0022] ...

example 1

[0035] The following example prepares the composite molecular sieve of the present invention.

[0036] (1) Take 15 grams of SiO 2 / Al 2 o 3 For HZSM-5 molecular sieve with a molar ratio of 42, use 20ml of an aqueous solution containing 1.929 grams of ammonium dihydrogen phosphate, impregnate at 25°C for 8 hours, dry at 120°C for 4 hours, and roast at 550°C for 3 hours to obtain phosphorus-modified ZSM-5 molecular sieve P-ZSM-5.

[0037] (2) Combine P-ZSM-5 with 8.67g tetraethyl orthosilicate (produced by Beijing Chemical Reagent Company, SiO 2 content 28% by mass), 5.38g tetrapropylammonium bromide (Guangzhou Dayou Fine Chemical Factory) mixed with 20ml aqueous solution, placed in a polytetrafluoroethylene-lined crystallization kettle, 150 DEG C of static crystallization for 20 hours, Cool to 25°C, dry at 120°C for 4 hours, and bake at 550°C for 3 hours to obtain a composite molecular sieve whose inner layer is P-ZSM-5 and outer layer is Silicalite-1.

[0038] (3) The com...

example 2

[0041] Catalyst was prepared according to the method of Example 1, except that (4) step mixed uniformly with 3 grams of modified composite molecular sieve A and 17 grams of pure silicon ZSM-5 molecular sieve Silicalite-1, and tableted to obtain catalyst H.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com