Electrolyte for lithium titanate battery and battery product prepared from electrolyte

A lithium titanate battery and electrolyte technology, which is applied in the direction of secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems affecting battery cycle and safety performance, large specific surface area of lithium titanate, and easy flatulence of batteries, etc., to achieve Conducive to widespread application, good high-temperature storage performance and cycle performance, and the effect of reducing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

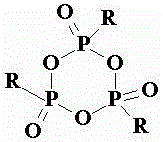

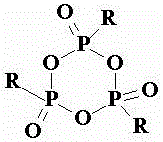

[0024] Embodiment 1: A kind of electrolyte solution for lithium titanate battery provided in this embodiment, it is formed by mixing solute, solvent and additive, and described additive is alkyl phosphoric anhydride, and the structural formula of this alkyl phosphoric anhydride is as follows:

[0025]

[0026] Wherein the alkyl group R is a C1-C5 alkyl group, and the mass percent content of the alkyl phosphoric anhydride in the lithium titanate battery electrolyte is 0.1%.

[0027] Preferably, the solvent is ethylene carbonate (EC), propylene carbonate (PC), dimethyl carbonate (DMC), diethyl carbonate (DEC), ethyl methyl carbonate (EMC), methyl propyl carbonate (MPC), methyl acetate (MA), ethyl acetate (EA), propyl acetate (PA), methyl propionate (MP), ethyl propionate (EP), propyl propionate (PP), butyl A combination of one or more of methyl butyrate (MB), ethyl butyrate (EB), γ-butyrolactone (GBL), acetonitrile (CH3CN), and tetrahydrofuran (THF).

[0028] The solute is l...

Embodiment 2

[0032] Embodiment 2: a kind of electrolyte solution for lithium titanate battery and its battery products provided by this embodiment, it is basically the same as embodiment 1, the difference is that the mass of the alkyl phosphoric anhydride in the electrolyte solution for lithium titanate battery Min content is 0.2%.

Embodiment 3

[0033] Embodiment 3: a kind of lithium titanate battery electrolyte and its battery products provided by this embodiment, it is basically the same as embodiment 1, the difference is that the quality of the alkyl phosphoric anhydride in the lithium titanate battery electrolyte Min content is 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com