Method for improving stability of SEI membrane of lithium ion battery

A lithium-ion battery and membrane stability technology, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries, can solve the problems of insufficient improvement effect, high inertia, and no high performance of ion batteries, and achieves The effect of excellent retention rate, improved stability, and improved high temperature cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: a kind of method that improves the stability of lithium-ion battery SEI film, comprises the following steps:

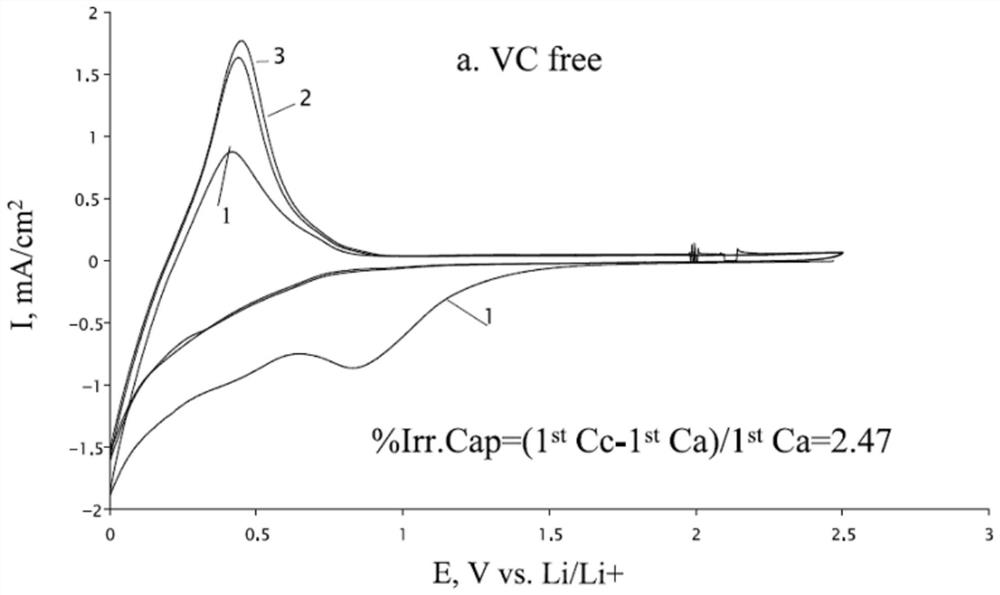

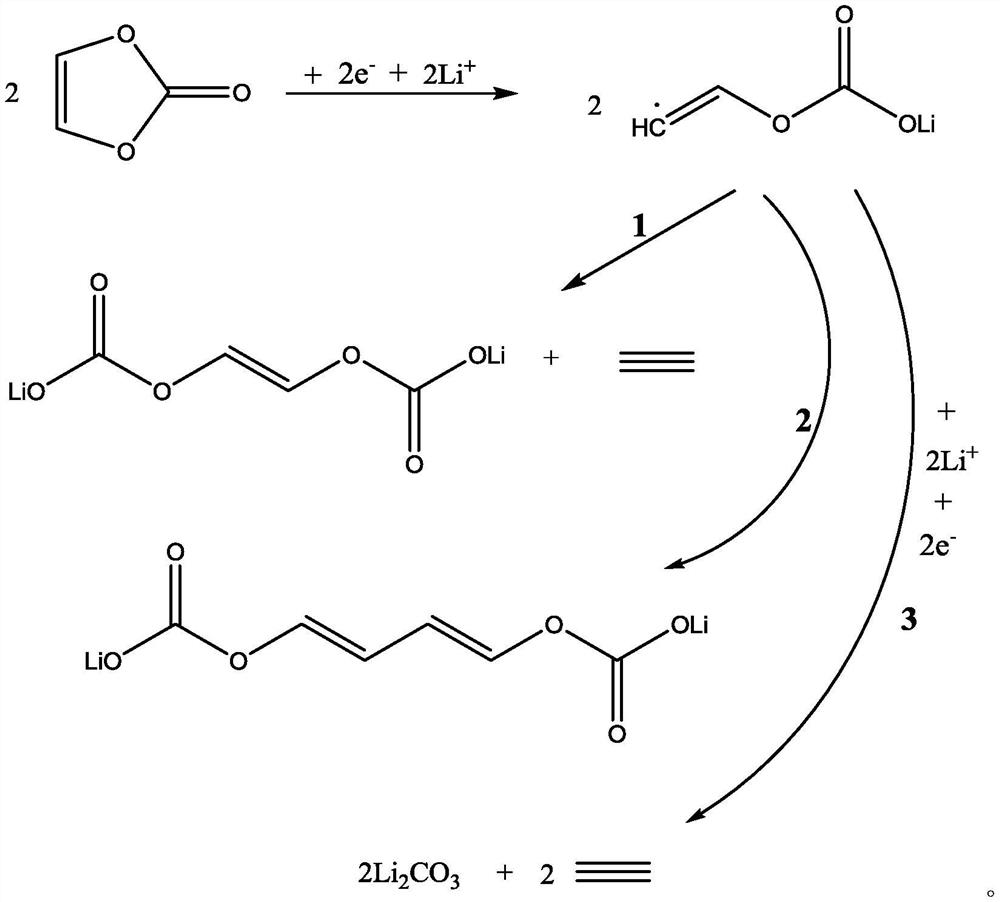

[0041]S1: First, keep the lithium-ion battery cell, electrolyte solvent and electrolyte added with lithium salt and 0% VC (vinylene carbonate) stabilizer at a constant temperature of 25±2°C for standby;

[0042] S2: Weigh the lithium-ion battery cell, the mass of the lithium-ion battery cell is m, put the lithium-ion battery cell into the vacuum system to vacuum to a vacuum degree of -0.08~-0.1Mpa, and the vacuum time is 95S;

[0043] S3: Inject the electrolyte solution (including VC stabilizer) into the lithium-ion battery dry cell kept in vacuum and let it stand for 10 seconds;

[0044] S4: After breaking the vacuum, fill it with inert gas to pressurize, keep the internal positive pressure of the cell at 0.5-1.0Mpa, hold the pressure for 80S, and pressurize twice continuously;

[0045] S5: After the pressure is released, the vacuum is pumped ag...

Embodiment 2

[0047] Embodiment 2: a kind of method that improves the stability of lithium-ion battery SEI film, comprises the following steps:

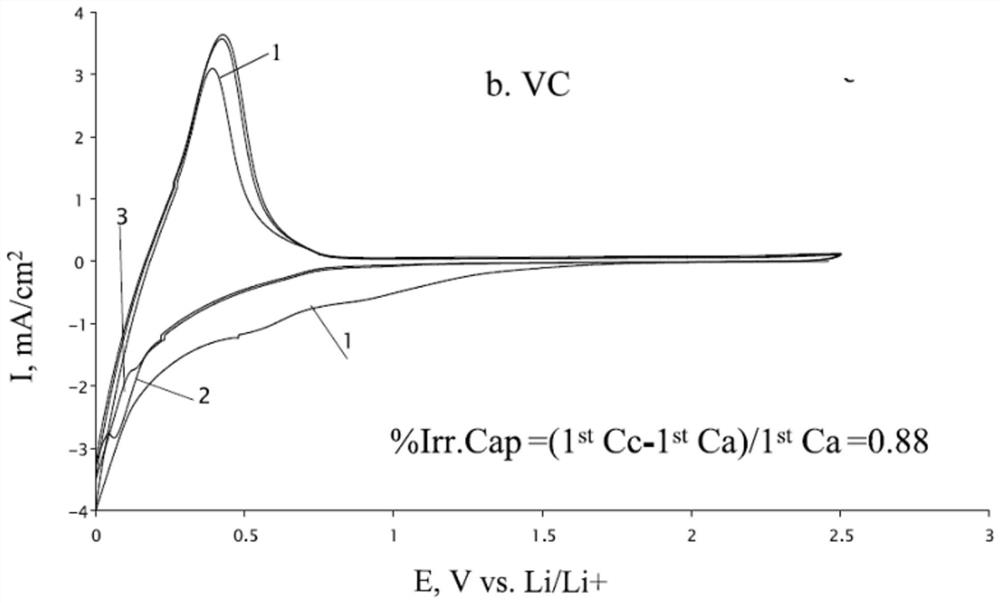

[0048] S1: First, keep the lithium-ion battery cell, electrolyte solvent and electrolyte added with lithium salt and 0.5% VC (vinylene carbonate) stabilizer at a constant temperature of 25±2°C for later use;

[0049] S2: Weigh the lithium-ion battery cell, the mass of the lithium-ion battery cell is m, put the lithium-ion battery cell into the vacuum system to vacuum to a vacuum degree of -0.08~-0.1Mpa, and the vacuum time is 95S;

[0050] S3: Inject the electrolyte solution (including VC stabilizer) into the lithium-ion battery dry cell kept in vacuum and let it stand for 10 seconds;

[0051] S4: After breaking the vacuum, fill it with inert gas to pressurize, keep the internal positive pressure of the cell at 0.5-1.0Mpa, hold the pressure for 80S, and pressurize twice continuously;

[0052] S5: After the pressure is released, the vacuum is pump...

Embodiment 3

[0054] Embodiment 3: a kind of method that improves the stability of lithium-ion battery SEI film, comprises the following steps:

[0055] S1: First, keep the lithium-ion battery cell, electrolyte solvent, and electrolyte added with lithium salt and 1% VC (vinylene carbonate) stabilizer at a constant temperature of 25±2°C for later use;

[0056] S2: Weigh the lithium-ion battery cell, the mass of the lithium-ion battery cell is m, put the lithium-ion battery cell into the vacuum system to vacuum to a vacuum degree of -0.08~-0.1Mpa, and the vacuum time is 95S;

[0057] S3: Inject the electrolyte solution (including VC stabilizer) into the lithium-ion battery dry cell kept in vacuum and let it stand for 10 seconds;

[0058] S4: After breaking the vacuum, fill it with inert gas to pressurize, keep the internal positive pressure of the cell at 0.5-1.0Mpa, hold the pressure for 80S, and pressurize twice continuously;

[0059] S5: After the pressure is released, the vacuum is pumpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com