A kind of exhaust valve head material and preparation method thereof

A technology of exhaust valve and head, which is applied in the field of exhaust valve head materials and its preparation, can solve the problems of not being able to meet the requirements of engines in different working conditions, reduce life fatigue failure, and poor high temperature stability, and achieve improved The effects of compactness and purity, high fatigue strength, and stable organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

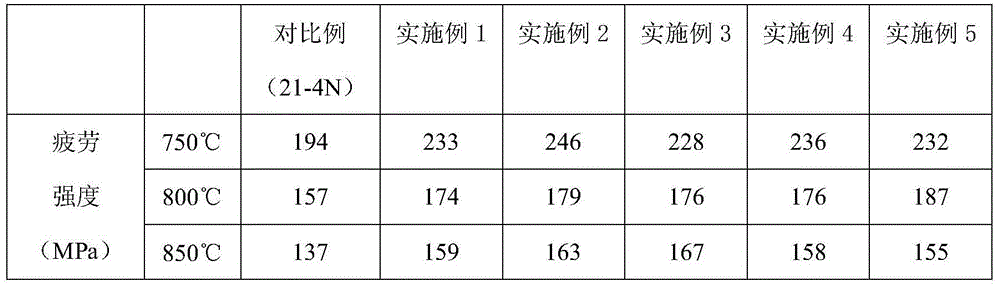

Examples

Embodiment 1

[0016] The exhaust valve head material is prepared by low-pressure casting, rolling, and heat treatment. The specific steps are as follows:

[0017] (1) Ingredients, the alloy weight percentage composition of the exhaust valve head material is: C: 0.32%; Si: 0.17%; Mo: 3.0%; Mn: 6.50%; Cr: 22%; W: 0.50%; Ni : 3.0%; Surplus material is the Fe that purity is 99.8%, alloy material is mixed evenly;

[0018] (2) Melting in a vacuum induction furnace at a temperature of 1620°C for 1.5 hours;

[0019] (3) Low-pressure casting is adopted, and the process conditions of low-pressure casting are: filling pressure 0.06MPa, filling speed 50mm / s, filling pressurization 0.01MPa, pressure holding time 10s, rolling 3 times, and the casting is rolled again Forming, rolling three times, the deformation of the last rolling is 45%;

[0020] (4) Heating to 1050°C for 1 hour, then quenching;

[0021] (5) Heating to 800°C for 4 hours and quenching to obtain the exhaust valve head material. The hi...

Embodiment 2

[0023] The exhaust valve head material is prepared by low-pressure casting, rolling, and heat treatment. The specific steps are as follows:

[0024] (1) Ingredients, the alloy weight percentage composition of the exhaust valve head material is: C: 0.40%; Si: 0.25%; Mo: 3.0%; Mn: 6.80%; Cr: 21.1%; W: 1.0%; Ni : 3.2%; Surplus material is the Fe that purity is 99.8%, alloy material is mixed evenly;

[0025] (2) Melting in a vacuum induction furnace at a temperature of 1680°C for 1.5 hours;

[0026] (3) Low-pressure casting is adopted, and the process conditions of low-pressure casting are: filling pressure 0.06MPa, filling speed 50mm / s, filling pressurization 0.01MPa, pressure holding time 10s, rolling 3 times, and the casting is rolled again Forming, rolling three times, the deformation of the last rolling is 45%;

[0027] (4) Heating to 1150°C for 0.5 hours, then quenching;

[0028] (5) Heating to 820°C for 3 hours and quenching to obtain the exhaust valve head material. Th...

Embodiment 3

[0030] The exhaust valve head material is prepared by low-pressure casting, rolling, and heat treatment. The specific steps are as follows:

[0031] (1) Ingredients, the alloy weight percentage composition of the exhaust valve head material is: C: 0.34%; Si: 0.37%; Mo: 2.75%; Mn: 6.60%; Cr: 20.00%; W: 0.80%; Ni : 2.9%; the remaining material is Fe with a purity of 99.8%, and the alloy material is mixed evenly;

[0032] (2) Melting in a vacuum induction furnace at a temperature of 1650°C for 1.5 hours;

[0033] (3) Low-pressure casting is adopted, and the process conditions of low-pressure casting are: filling pressure 0.06MPa, filling speed 50mm / s, filling pressurization 0.01MPa, pressure holding time 10s, rolling 3 times, and the casting is rolled again Forming, rolling three times, the deformation of the last rolling is 55%;

[0034] (4) Heating to 1100°C for 0.5 hours, then quenching;

[0035] (5) Heating to 800°C for 3 hours and quenching to obtain the exhaust valve hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com