High temperature anticorrosive method by using self-reaction products

A reaction product, high temperature technology, applied in the direction of phosphorus oxide, etc., can solve the problems of increasing the difficulty and complexity of control, increasing energy consumption, unfavorable promotion and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

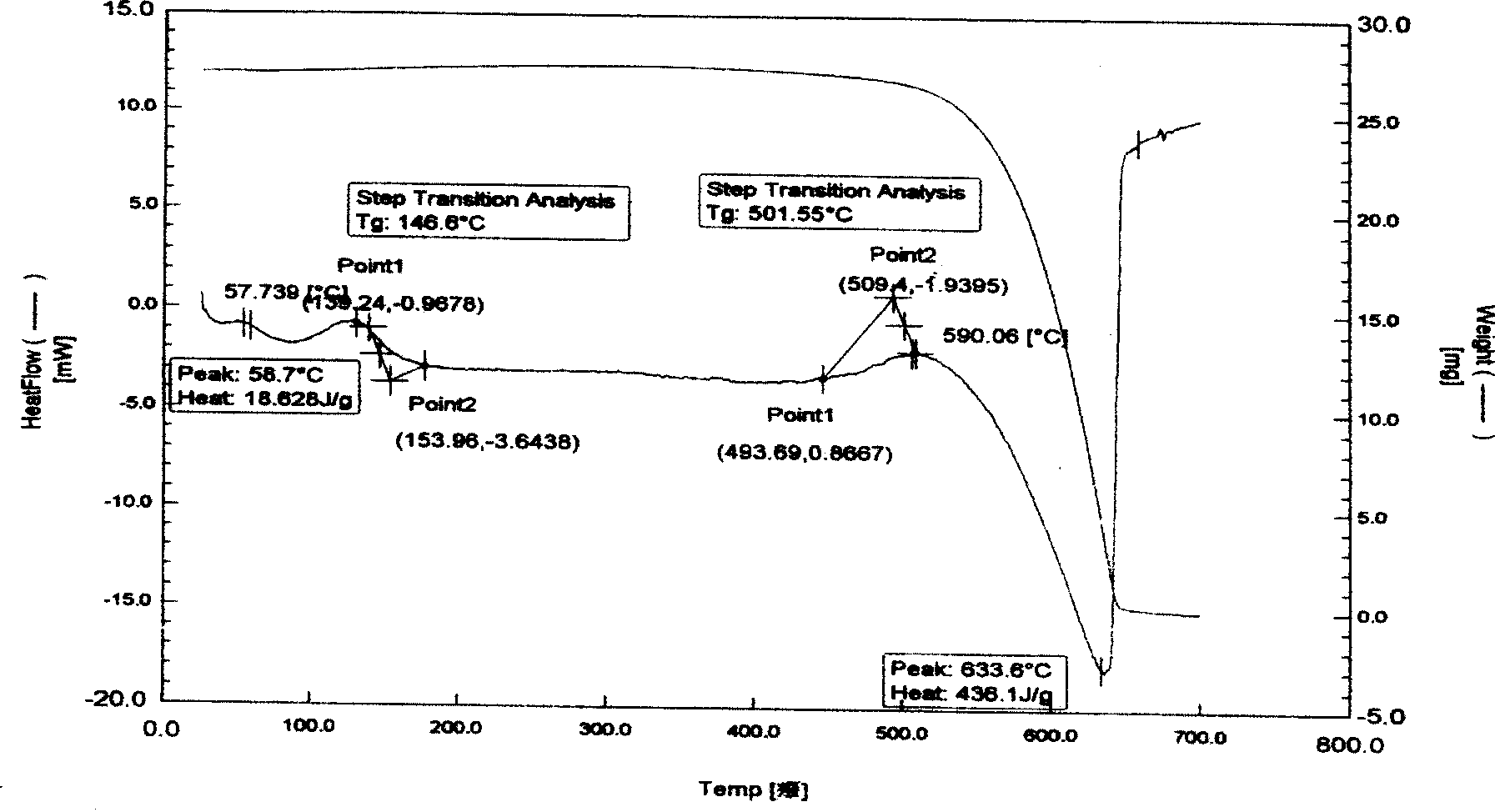

[0019] The high-temperature anti-corrosion method using self-reaction products of the present invention is to use the reaction products produced in the production process of burning yellow phosphorus to produce phosphorus pentoxide to realize high-temperature anti-corrosion. The anti-corrosion method is as follows:

[0020] a. At normal temperature and pressure, the air leading to the combustion tower made of austenitic stainless steel is untreated non-dry air,

[0021] b. In the process of yellow phosphorus burning to generate phosphorus pentoxide, the mol ratio of its moisture and the phosphorus pentoxide produced by the reaction is controlled between 0.01~0.8, and the combustion tower wall temperature is reduced by cooling the combustion tower wall surface simultaneously, and Control the wall temperature below 490°C;

[0022] c. When yellow phosphorus burns, conjunctiva is formed on the tower wall, and the conjunctiva is super phosphoric acid.

[0023] In a set of thermal ...

Embodiment 2

[0025] In the yellow phosphorus combustion tower industrial device made of austenitic stainless steel, under normal natural air conditions, a two-step method is used to burn yellow phosphorus to produce thermal phosphoric acid and recover the reaction heat of yellow phosphorus. During the production process, the inner wall temperature of the control tower is lower than 350°C. After six months of continuous production, the conjunctiva was obtained from the inner wall of the combustion tower. The iron ion content in the conjunctiva is 9ppm, which shows that the conjunctiva has little corrosion to austenitic stainless steel and fully meets the requirements of production for equipment materials. All the other are with embodiment 1.

Embodiment 3

[0027]On a set of thermal phosphoric acid two-step production equipment put into operation in a certain place, the temperature is 30°C, the relative air humidity is 100% during two consecutive months of operation, and the air excess coefficient is 1.4, that is, the moisture in the combustion tower and the five gases produced by the reaction. The molar ratio of phosphorus oxide is 0.728. After stopping the vehicle for inspection, the conjunctiva in the tower was intact. Five days later, the conjunctiva melted and there was no trace of corrosion on the inner surface of the equipment, indicating that under this condition, conjunctiva will still form. The use of austenitic stainless steel can meet the requirements of burning yellow phosphorus. Long-term operation requirements of combustion tower equipment in the production process of phosphorus pentoxide or thermal phosphoric acid. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com