Patents

Literature

30results about How to "Reduce the difficulty of operation control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

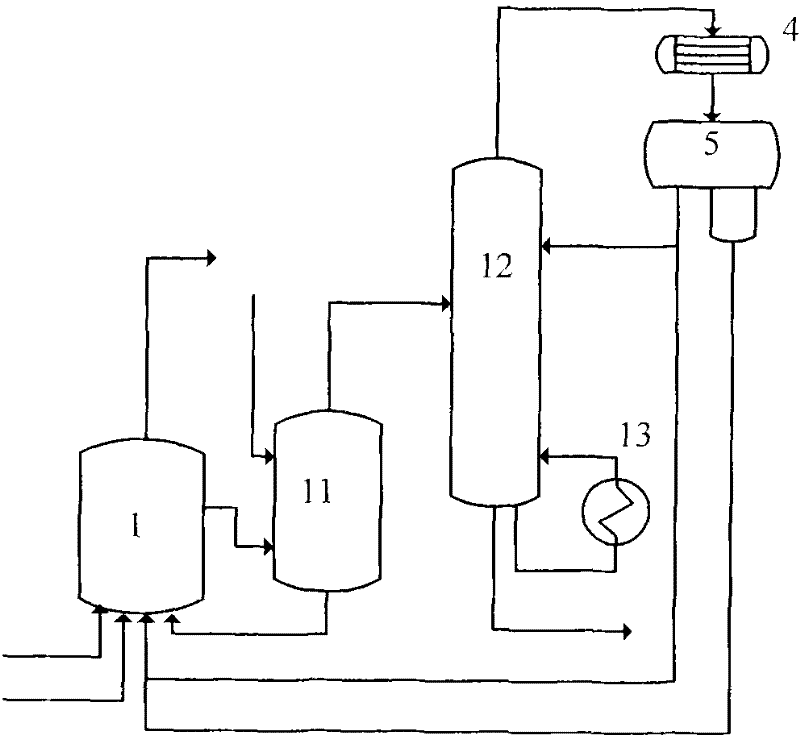

Method and apparatus for synthesizing acetic acid by methanol low-voltage carbonylation

ActiveCN101503346ASimplify the process routeShortened return routeCarboxylic preparation from carbon monoxide reactionCarboxylic compound separation/purificationProtein carbonylCarbonyl group

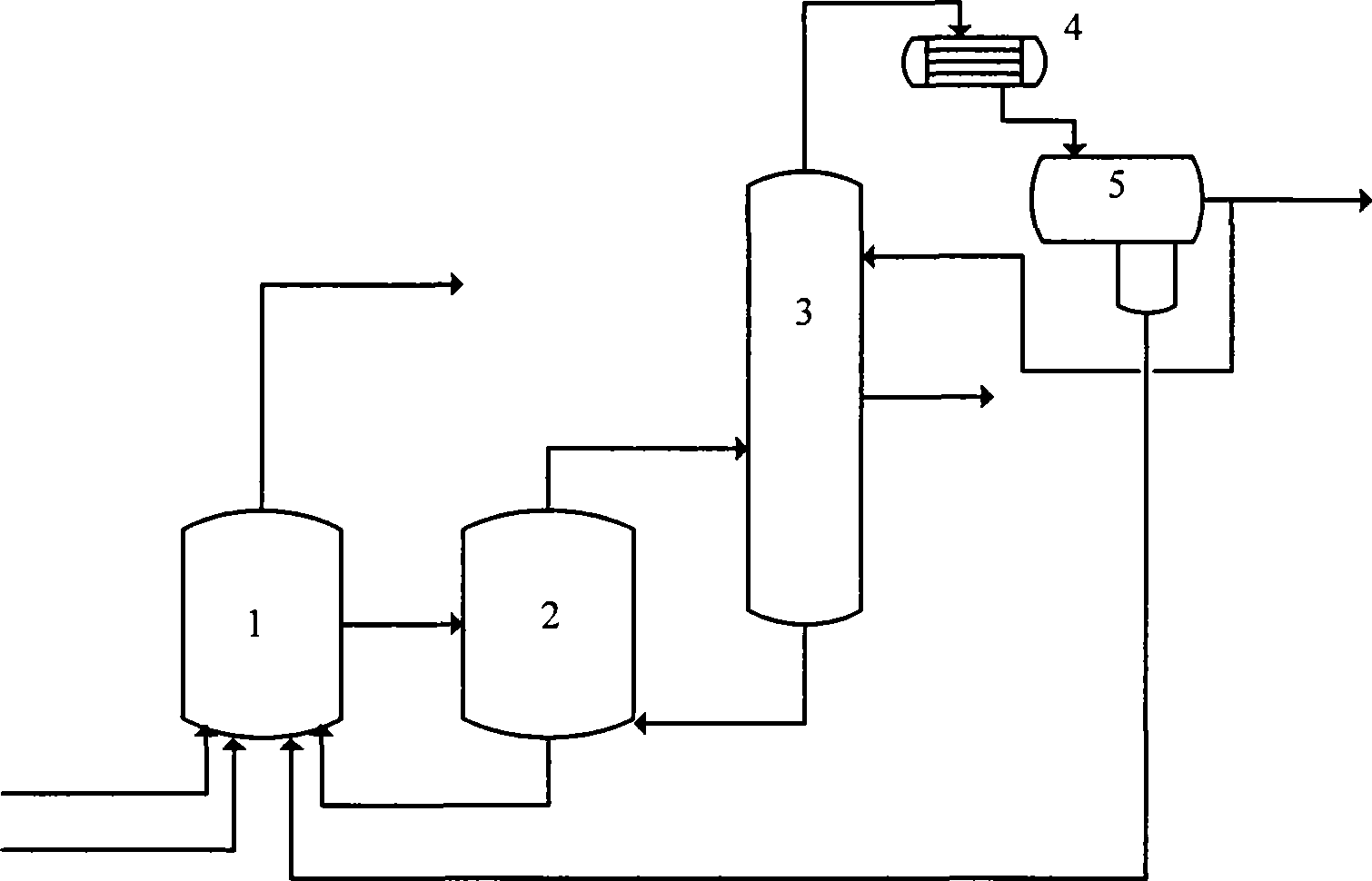

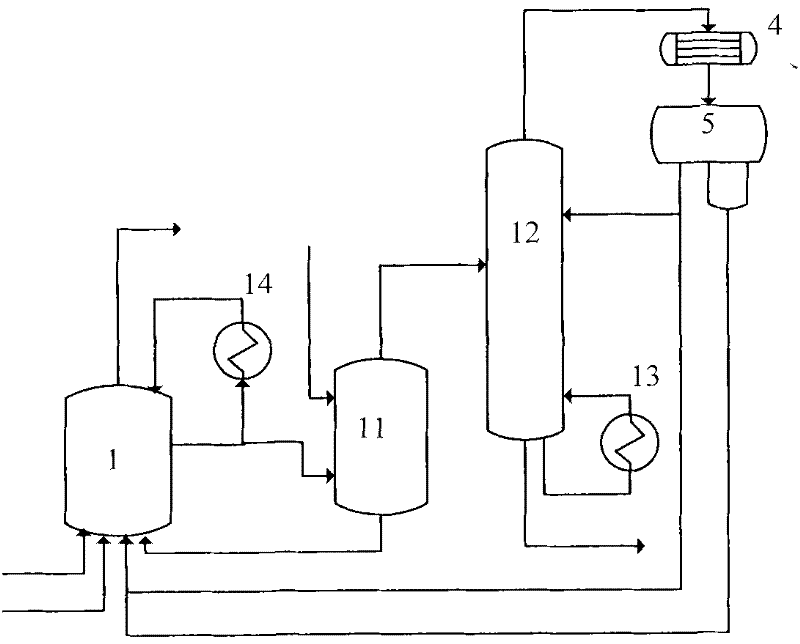

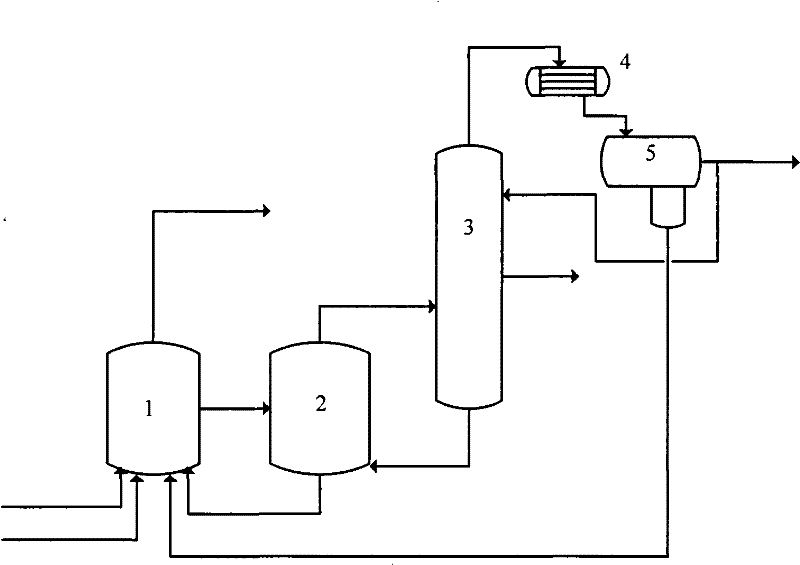

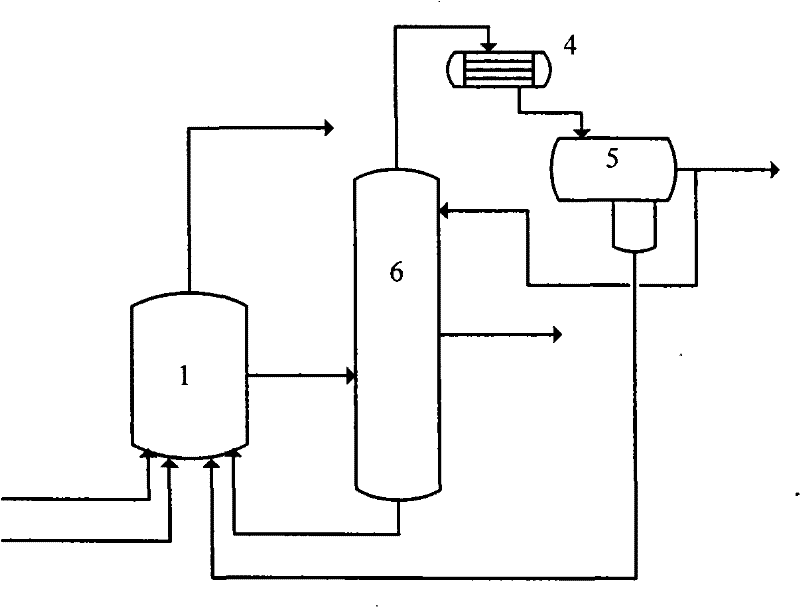

The invention relates to a method for chemically synthesizing acetic acid by using methanol low pressure carbonyl and a device thereof, belonging to the technical field of chemical engineering. The method comprises: methanol and carbon monoxide firstly react in a reactor filled with reaction liquid to generate the acetic acid, and then the reaction liquid enters a multifunctional tower to be processed by flash evaporation and lightness removal to lead overhead fraction of the multifunctional tower to enter a condenser, so that part of light phase in the condensate liquid flows and returns to a lightness removing section of the multifunctional tower, and heavy phase returns to the reactor to continuously take part in the reaction. The method combines the functions of the existing evaporator and lightness removing tower into the multifunctional tower, so as to simplify the flow route of acetic acid preparation, shorten the returning route of catalyst, be beneficial to maintaining the stable property of the catalyst and reducing the loss of the catalyst; the existing evaporator and lightness removing tower are combined into a whole, so that the equipment investment is reduced and the difficulty of operation and control can be lowered.

Owner:BEIJING ZEHUA CHEM ENG

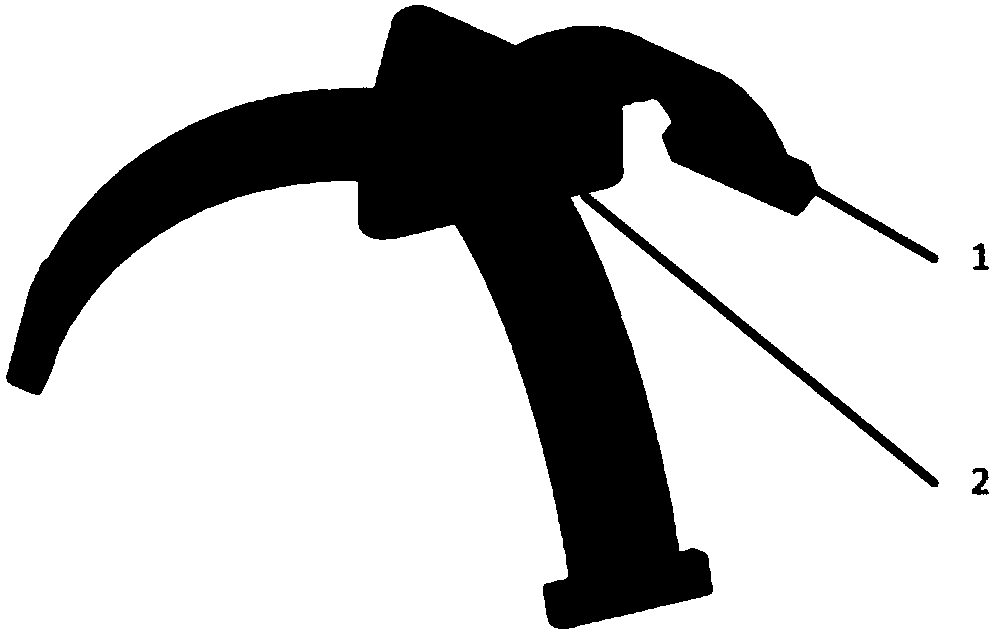

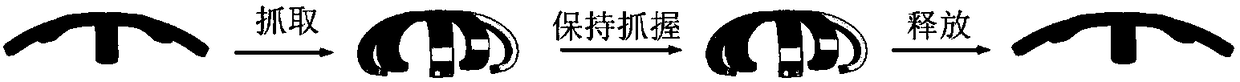

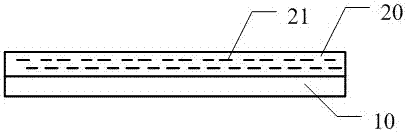

Clamping device based on shape memory alloy wires and control method of clamping device

InactiveCN108161921AReduce the difficulty of operation controlImprove scalabilityProgramme-controlled manipulatorMicrocomputerMicrocontroller

The invention discloses a clamping device based on shape memory alloy wires and a control method of the clamping device. The clamping device comprises a connecting piece (2) and clamping arms (1). Clamping arms (1) are composed of PCBs and the shape memory alloy wires. Totally two PCBs are arranged, and the multiple sections of shape memory alloy wires which are arranged in parallel in a coplane manner are arranged between the two PCBs. The multiple clamping arms (1) are arranged, and one ends of the clamping arms (1) are connected with the connecting piece (2). The shape memory alloy wires ofthe multiple clamping arms (1) are connected with a single-chip microcomputer, the single-chip microcomputer conducts independent heating control on each clamping arm (1) through adjustment on the voltage waveform according to timing sequence parameters corresponding to different modes, and the clamping arms (1) finish the tight holding or loosening action. According to the clamping device and the control method thereof, grabbing, holding, stacking and other actions can be finished, operation control difficulty is low, and expandability is high.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

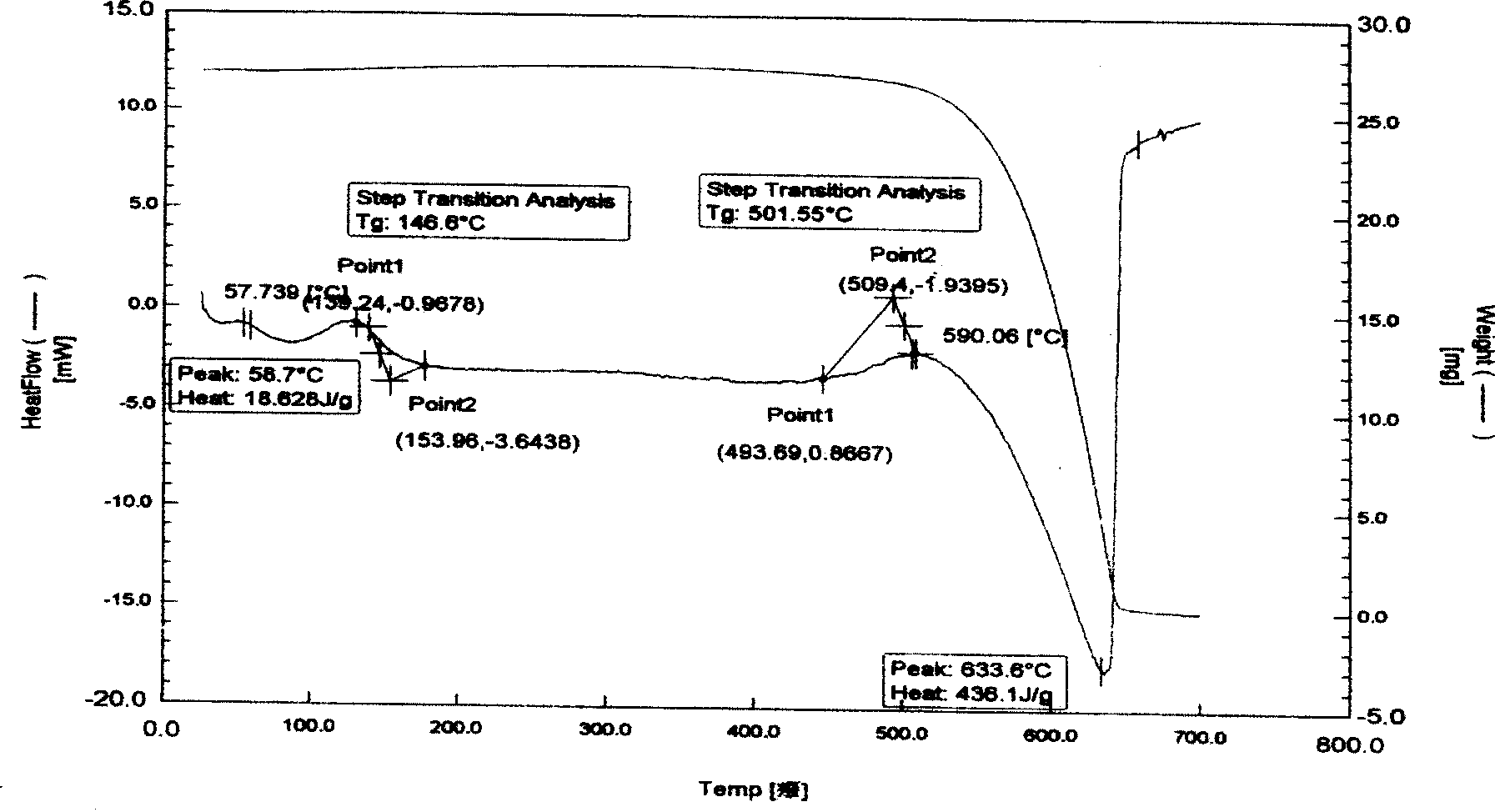

High temperature anticorrosive method by using self-reaction products

InactiveCN101456544AAvoid corrosionStable structurePhosphorus oxidesPhosphoric acidHigh-temperature corrosion

The invention relates to a method for high-temperature corrosion protection by utilizing self reaction products, in particular to anticorrosive technology for a combustion tower in production technology for preparing phosphoric anhydride or thermal phosphoric acid by combustion of yellow phosphorus. The method is to utilize the reaction products generated in the production process of preparing the phosphoric anhydride by combustion of the yellow phosphorus to realize high-temperature corrosion protection. The method is characterized by comprising: a, air pumped into the combustion tower at normal temperature and pressure is non-dried air at normal temperature and pressure; b, the wall surface of the combustion tower is cooled to reduce the temperature of the wall surface of the combustion tower during production of the phosphoric anhydride by combustion of the yellow phosphorus, and the temperature of the wall surface of the combustion tower is controlled to be less than 490 DEG C; and c, conjunctival matters are formed on the tower wall during combustion of the yellow phosphorus. Various technological conditions required by the method are easy to realize, and the actual control difficulty is small. Moreover, the method can also reduce the energy consumption and the production cost, is suitable to be applied in mass industrial production, and has great promotion value.

Owner:YUNNAN CHEM RES INST

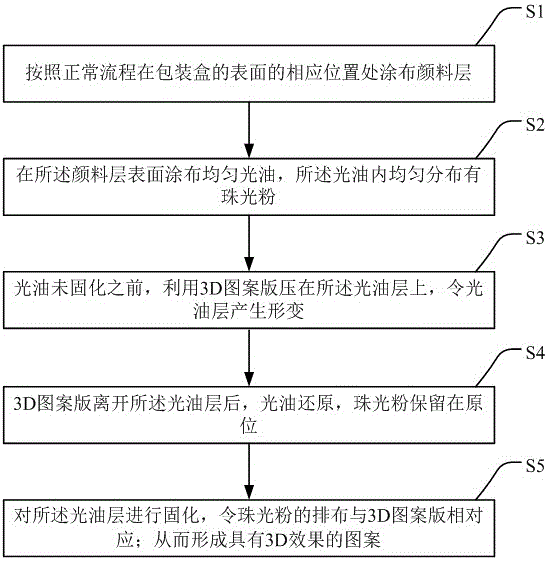

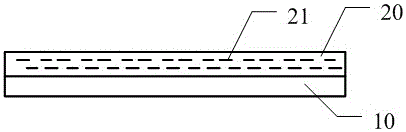

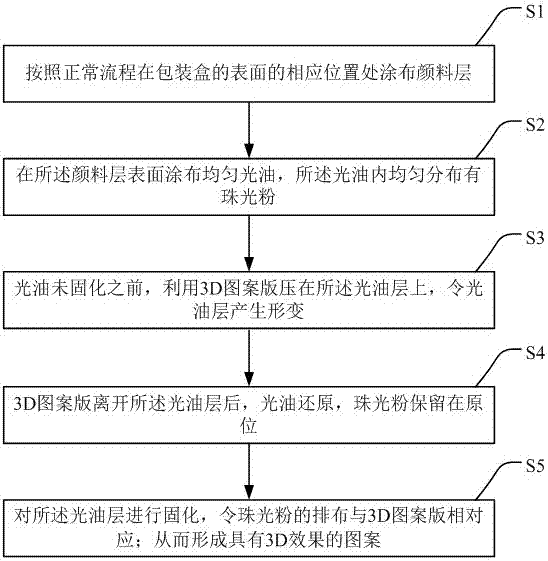

Packaging box with 3D effect and production method thereof

ActiveCN105015901ANo pollutionLow costCoverings/external coatingsOther printing apparatus3d patterningEngineering

The invention discloses a packaging box with a 3D effect and a production method thereof. According to the packaging box with the 3D effect, a color layer is coated with a light oil layer, pearl powder is arranged in the light oil layer and distributed in a preset rule, the distribution of the pearl powder is changed through press-printing of a 3D pattern plate, and therefore a pattern with a 3D effect is formed. All materials needed by production are degradable print materials and cannot pollute the environment. Meanwhile, raster sheets for attaching are not needed, cost is reduced, operation control difficulty is lowered, and the packaging box has good market application and popularization prospects.

Owner:江西丰彩丽印刷包装有限公司

Process of calcium carbonate carbon balls for converter or electric furnace steel tapping deoxidation

The invention discloses a process of calcium carbonate carbon balls for converter or electric furnace steel tapping deoxidation. Lime stones are grinded to powder with a particle size below 1 mm, are uniformly mixed with graphite carbons with a carbon content of 90%, and are pressed to calcium carbonate carbon balls with a diameter of 30 mm by a dry powder ball press, wherein the adding proportion of the lime stones is 93 mass% of the carbon balls; the adding proportion of the graphite carbons is 7 mass% of the carbon balls; the carbon content in the calcium carbonate carbon balls is controlled at 6 mass%; and in the steel tapping process of an electric furnace or a converter after smelting, 1.5 kg carbon balls are added in each tonnage of steel.

Owner:XINJIANG ZHONGHE DAZHENG COMMERCE & TRADE

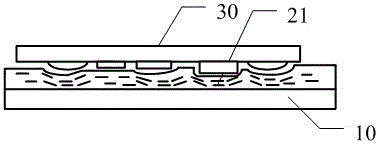

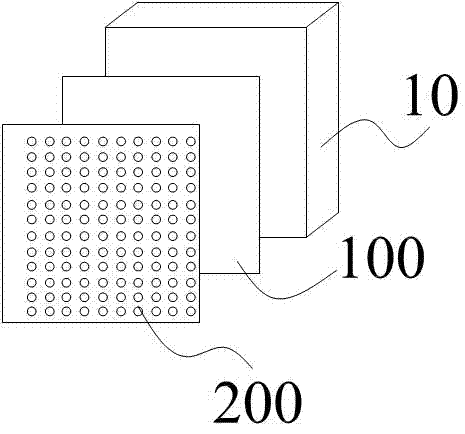

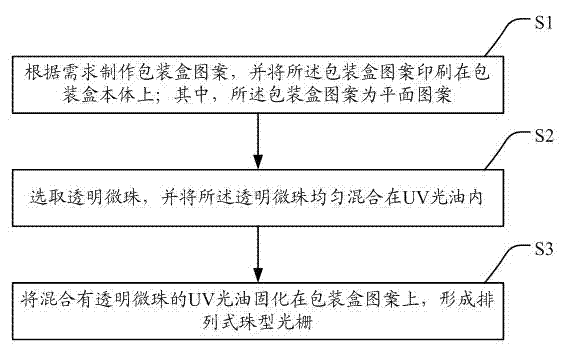

Packing box with suspension patterns and method for processing packing box

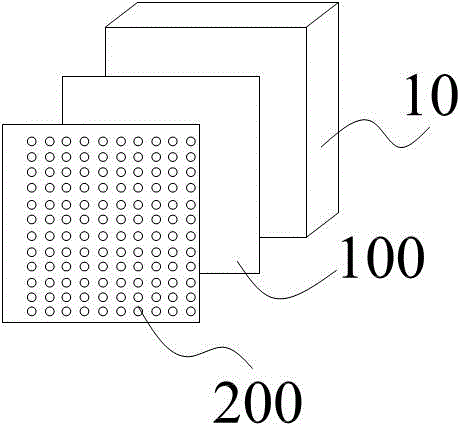

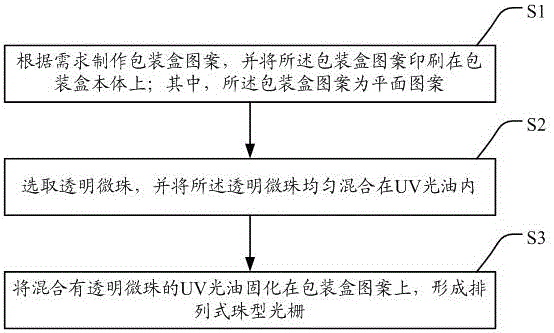

ActiveCN103587791AReduce the difficulty of operation controlNo pollutionCoverings/external coatingsGratingBead shape

The invention discloses a packing box with suspension patterns and a method for processing the packing box. The packing box is characterized in that a bottom pattern layer and a suspension effect layer are printed on a box body of the packing box with the suspension patterns, and the suspension effect layer is arranged on the bottom pattern layer; patterns on the bottom pattern layer are planar; the suspension effect layer comprises arrayed bead-shaped gratings, and transparent micro-beads are mixed in UV (ultraviolet) light oil to form the arrayed bead-shaped gratings. Compared with the prior art, the packing box and the method have the advantages that the patterns, which are manufactured according to requirements, of the packing box can be directly printed on the box body of the packing box without screen staggering printing, so that the time can be greatly saved; materials required by production are degradable printing materials, and accordingly environmental pollution can be prevented; transparent resin printing ink which is originally used as a printing material can be omitted, so that the cost can be saved.

Owner:SHENZHEN JINJIA GRP +1

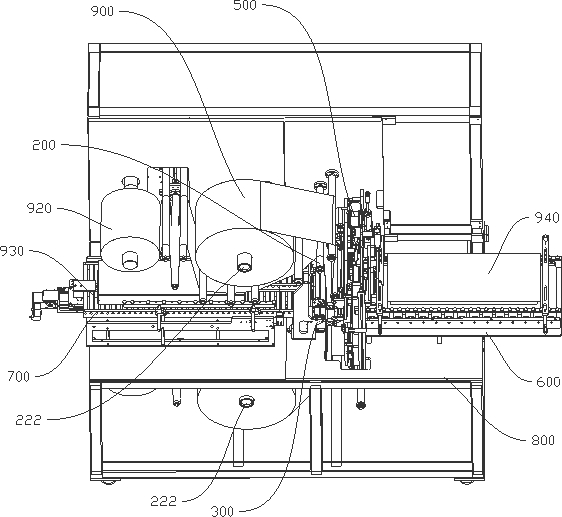

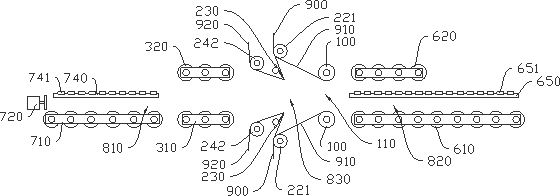

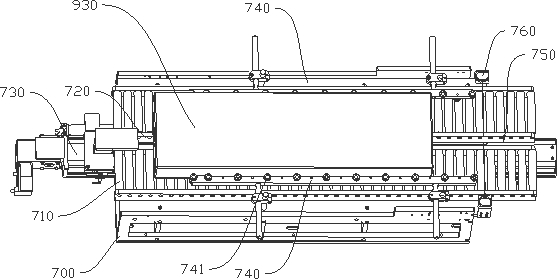

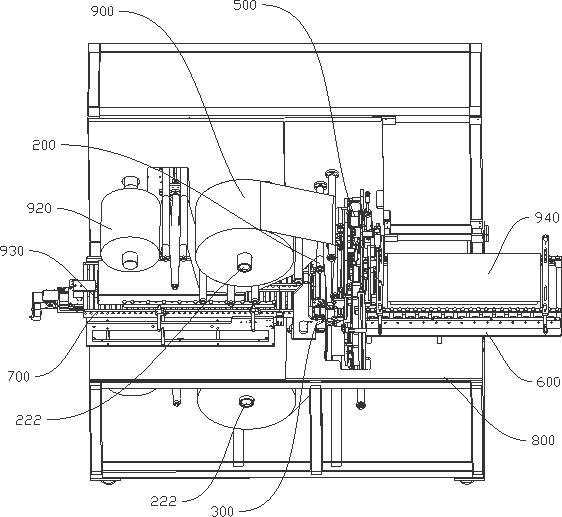

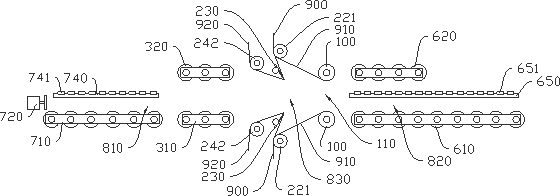

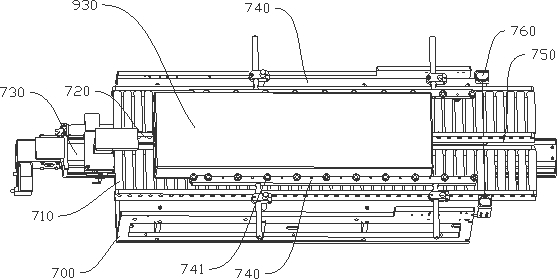

Film pasting equipment

ActiveCN113264409ASimple structureReduce the difficulty of operation controlFinal product manufactureSecondary cells manufactureCell fabricationMechanical engineering

Owner:SHENZHEN YUCHEN AUTOMATION EQUIP CO LTD

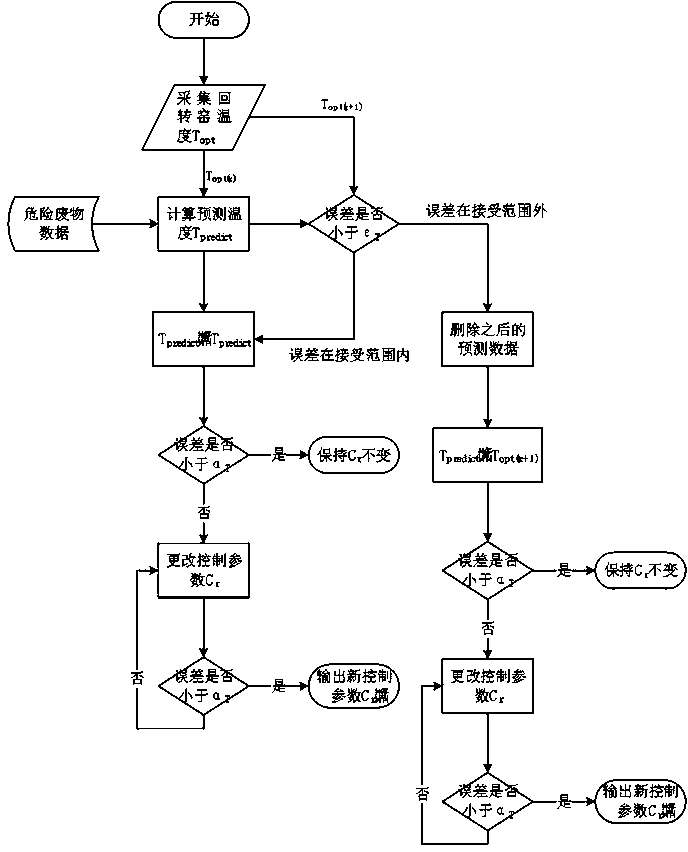

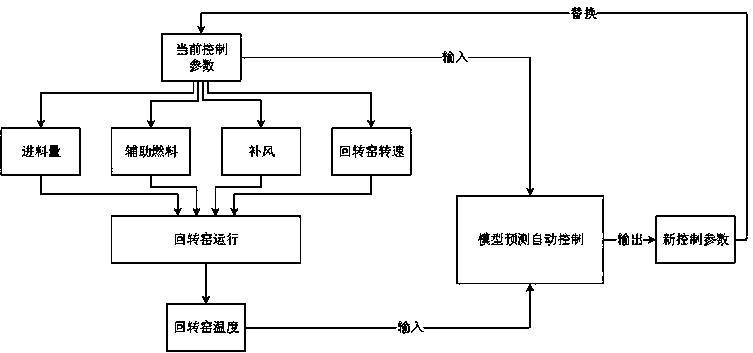

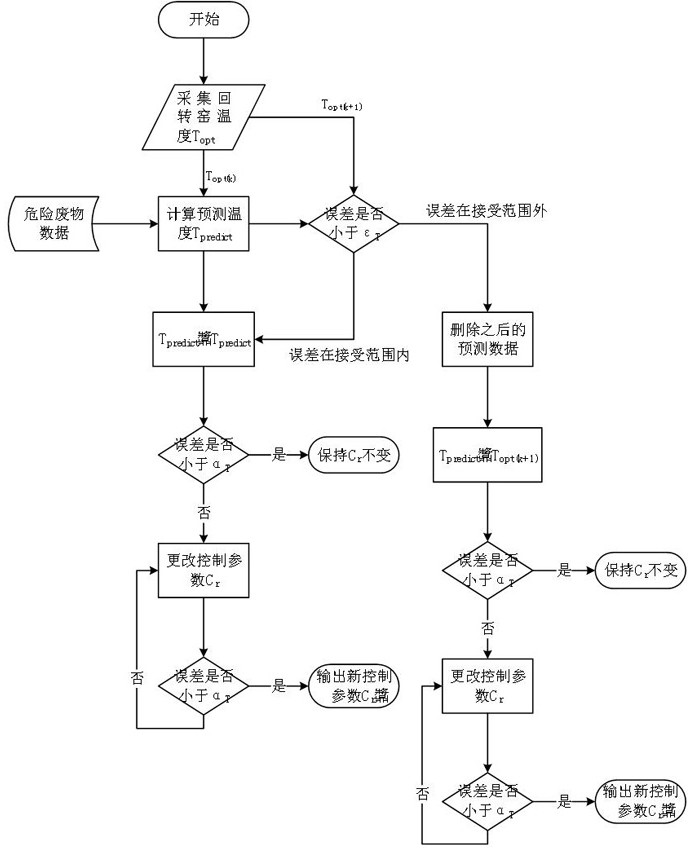

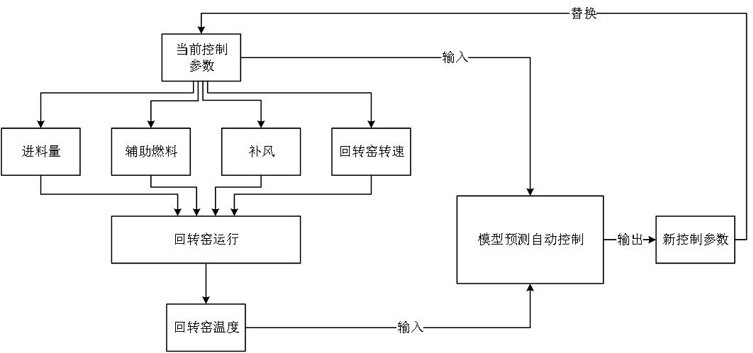

Data-driven modeling furnace temperature control method for hazardous waste incineration rotary kiln

ActiveCN109189120AReduce the difficulty of operation controlRealize automatic optimal controlTemperatue controlFurnace temperatureCombustion

The invention discloses a data-driven modeling furnace temperature control method for a hazardous waste incineration rotary kiln. The method comprises the following steps: S1: sampling and testing basic physical data of hazardous wastes to be processed, and obtaining the basic physical database of the hazardous wastes; S2: collecting rotary kiln operation data by using an incinerator DCS (Distributed Control System) system; S3: establishing a rotary kiln temperature fitting prediction model by adopting a self-regression sliding average modeling method according to the operation data of the rotary kiln and the basic physical database of the hazardous wastes; S4: predicting a temperature change in an operation of the rotary kiln according to the rotary kiln temperature fitting prediction model, and providing a control parameter correction value according to the predicted temperature; and S5: performing adaptive control on the operation of the rotary kiln in real time according to the modified control parameters, and making the rotary kiln run stably and smoothly. According to the data-driven modeling furnace temperature control method applied to the hazardous waste incineration rotary kiln, the automatic optimization control of the whole process of the rotary kiln feeding, combustion-supporting, wind supplementing and rotating speed adjustment are achieved, and the method has great help for improving the economic benefit of the hazardous waste rotary kiln.

Owner:FUZHOU UNIV

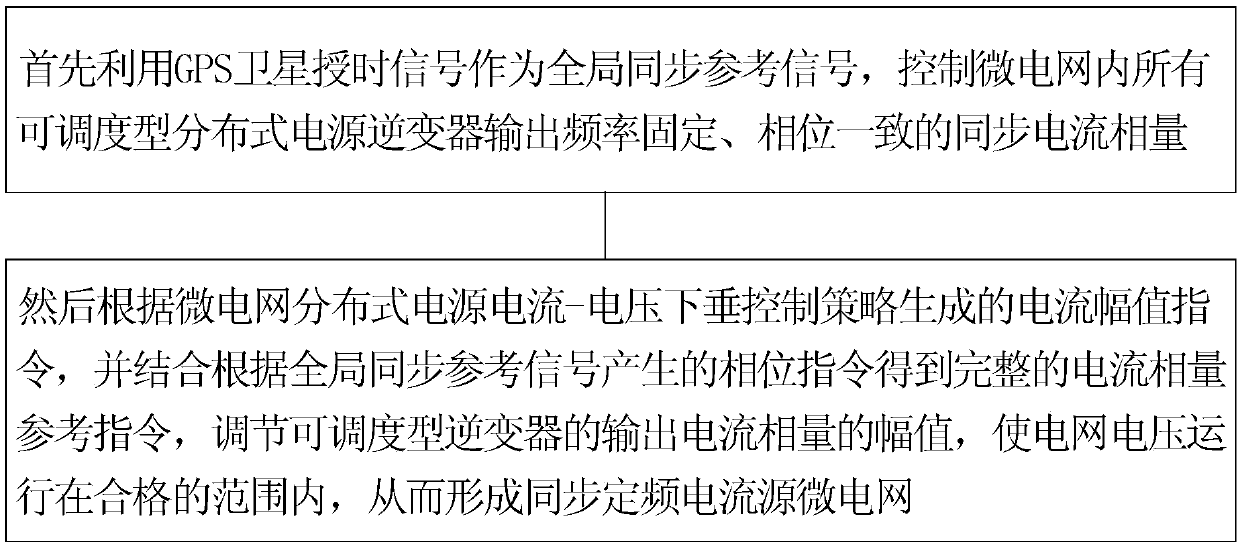

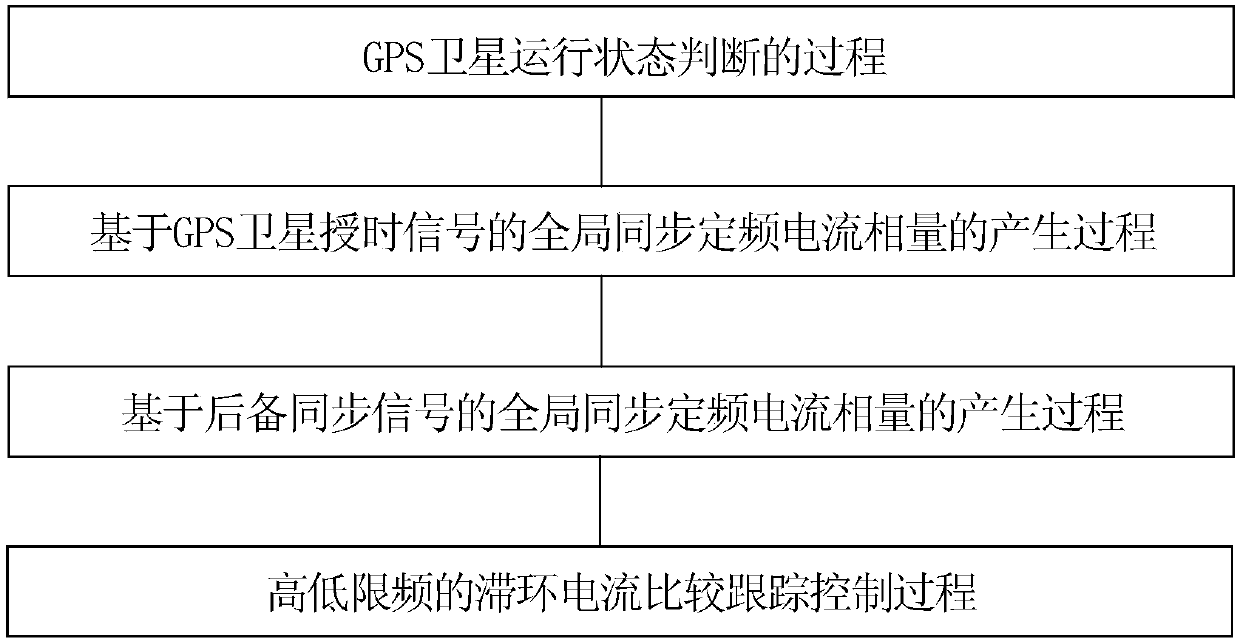

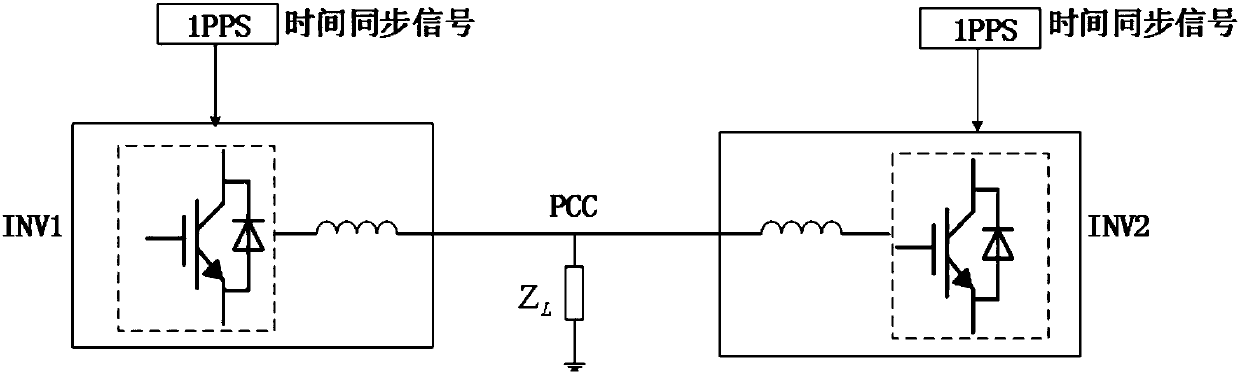

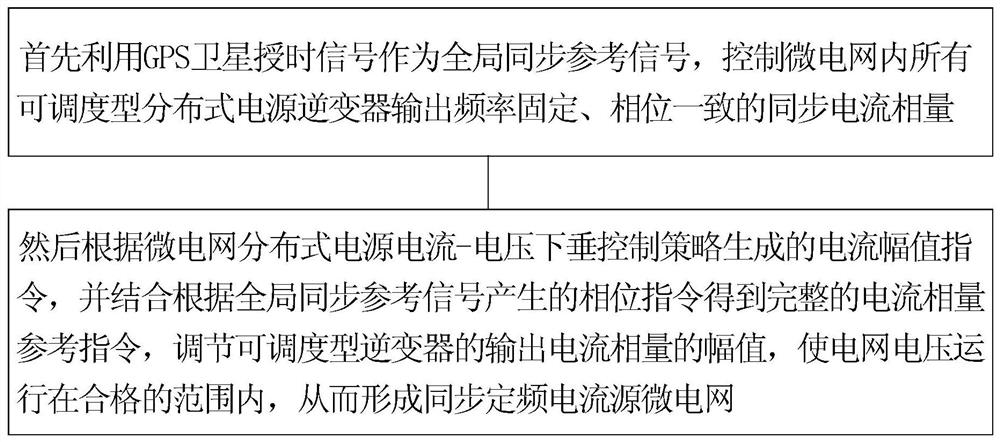

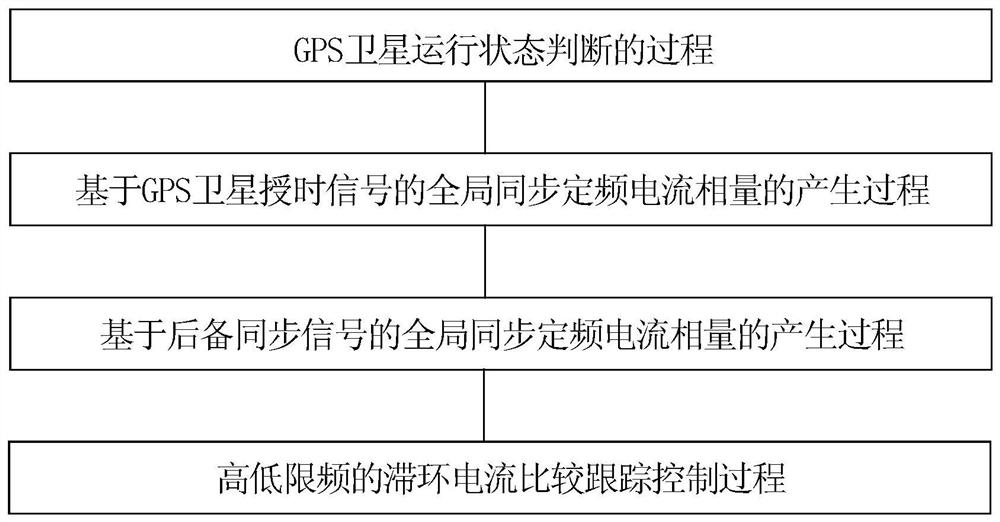

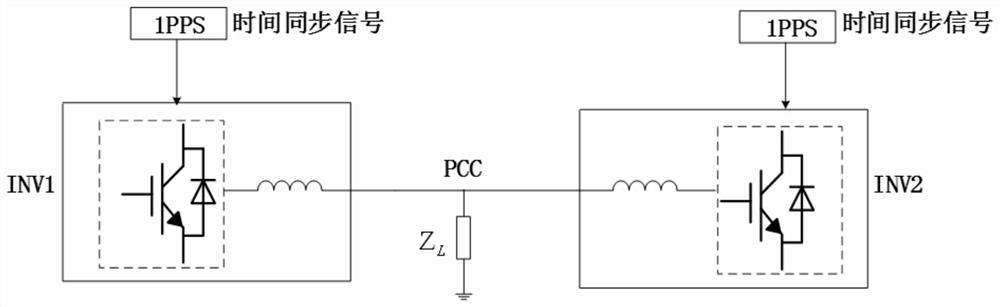

Generation method of synchronous fixed-frequency current phasors in full-inverter type microgrid

ActiveCN107732976AReduce the difficulty of operation controlFlexible and controllable frequencySingle network parallel feeding arrangementsMicrogridVoltage control

The invention discloses a generation method of synchronous fixed-frequency current phasors in a full-inverter type microgrid. A GPS satellite timing signal is used as a global synchronous reference signal so as to control the synchronous current phasors, which are constant in output frequency and coincident in phase, of all schedulable distributed power inverters in the microgrid; according to a microgrid distributed power current-voltage droop control strategy, a current amplitude instruction is generated, a complete current phasor reference instruction is obtained with the combination of a phase instruction generated according to the global synchronous reference signal, and the amplitudes of the output current phasors of the schedulable inverters are adjusted, so that the network voltageoperates within a qualified range, and a synchronous fixed-frequency current source microgrid is formed. In the generation method, the advantages that the amplitude, the frequency and the phase of the output voltage (current) of the inverters are flexibly controllable are given full play to, and the control over the operation of the microgrid is simplified into a single voltage control, so that the operation control difficulty of the full-inverter type microgrid is obviously reduced.

Owner:SHANDONG UNIV OF TECH +1

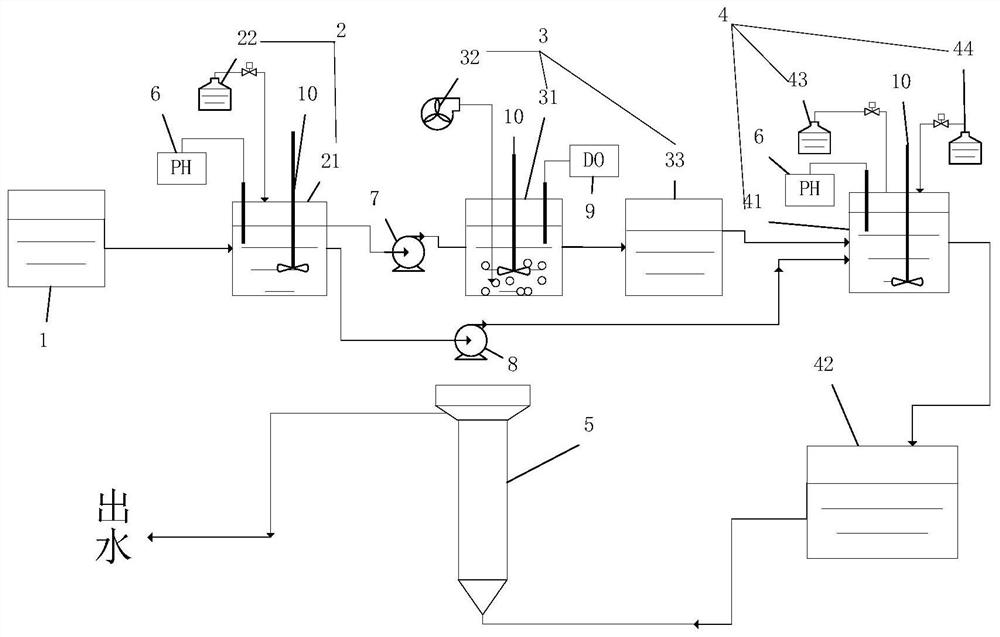

Ionic rare earth mine ammonia nitrogen tail water denitrification treatment device and treatment method

PendingCN112624335AReduce the difficulty of implementationEasy to control and implementWaste water treatment from quariesWater contaminantsPre treatmentRaw water

An ionic rare earth mine wastewater treatment device comprises a raw water tank, a pretreatment assembly, a nitrification reaction assembly, a short-cut denitrification reaction assembly and an anaerobic ammonia oxidation reaction assembly, wherein the pretreatment assembly is communicated with an outlet of the raw water tank, the nitrification reaction assembly is communicated with the pretreatment assembly through a first centrifugal pump, the short-cut denitrification reaction assembly is communicated with the nitrification reaction assembly, the short-cut denitrification reaction assembly is communicated with the pretreatment assembly through a second centrifugal pump, the anaerobic ammonia oxidation reaction assembly is communicated with the short-cut denitrification reaction assembly, and the anaerobic ammonia oxidation reaction assembly is used for carrying out anaerobic ammonia oxidation reaction and denitrification reaction on the wastewater from the short-cut denitrification reaction assembly. According to the device, by coupling the assemblies and setting the arrangement sequence of the assemblies and the distribution proportion of wastewater, the realization difficulty of an anaerobic ammonia oxidation denitrification process is reduced, the device is easy to control and realize, meanwhile, the energy consumption and organic carbon source consumption in the wastewater denitrification process can be reduced to the maximum extent, and the treatment cost of the wastewater denitrification process is remarkably saved.

Owner:赣州生态环境工程投资有限责任公司 +1

Method for quick glazing of ceramic multicolor glaze

InactiveCN106565279AAchieve multi-color decoration effectImprove operational efficiencyWater basedWax

The invention relates to the technical field of ceramics, in particular to a method for quick glazing of a ceramic multicolor glaze. The method can greatly reduce the operation control difficulty, simplify the technological process and improve production efficiency, stabilize the product quality and reduce the production cost, and can ensure clear patterns and smooth lines. The method for quick glazing of a ceramic multicolor glaze provided by the invention includes the steps of: 1) preparation of water-based wax; 2) glazing; 3) waxing; 4) cleaning after curing of water-based wax; and 5) repeating the step 2)-step 4).

Owner:陕西火凤凰艺术陶瓷有限责任公司

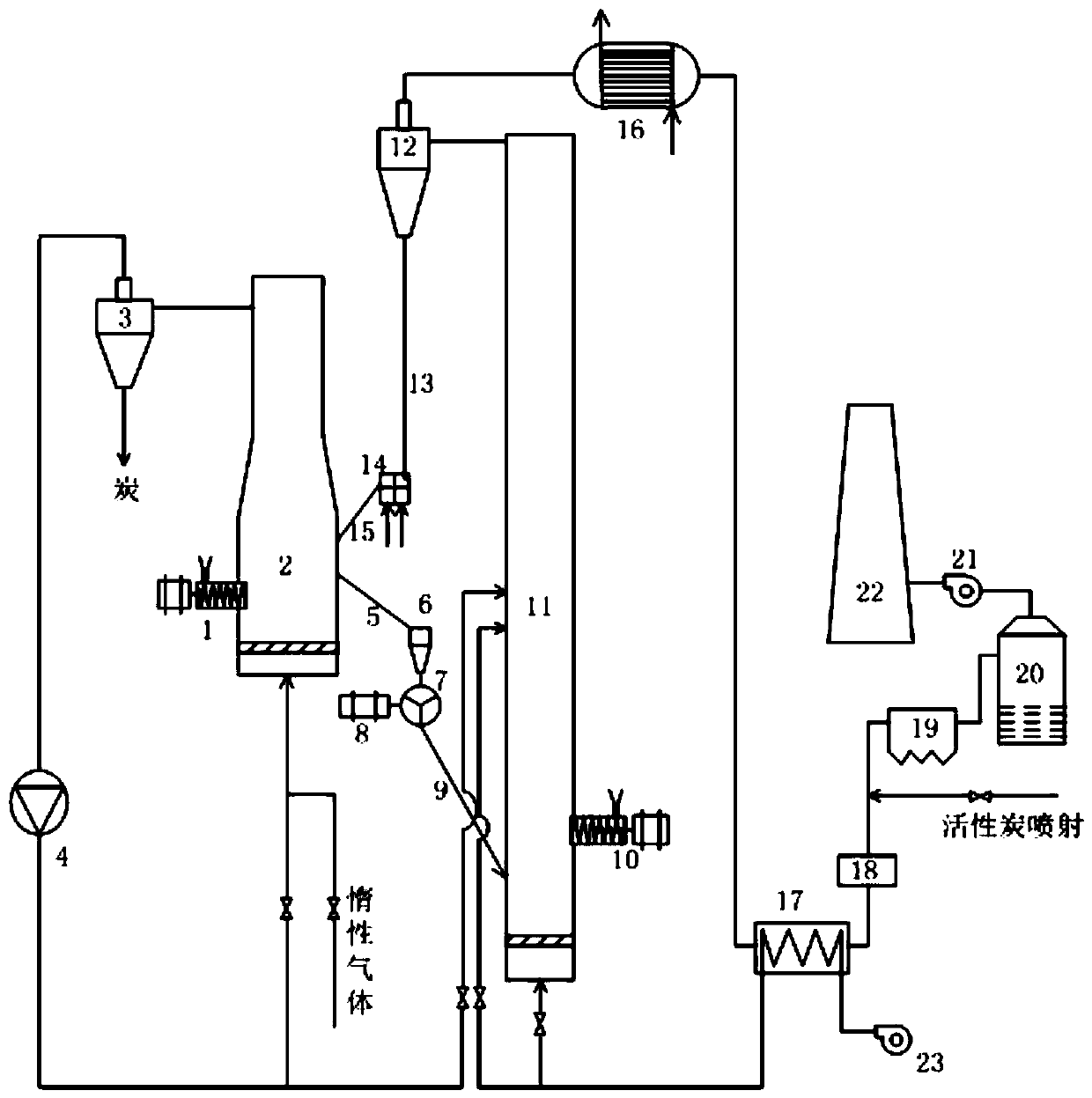

Combustible solid waste pyrolysis device and pyrolysis method

InactiveCN110484284ASimple structureEase of large-scale continuous productionDirect heating destructive distillationSpecial form destructive distillationHeat carrierProcess engineering

The invention discloses a combustible solid waste pyrolysis device and a pyrolysis method. The pyrolysis device comprises a fluidized bed pyrolysis reactor and a fluidized bed combustion reactor whichadopt heat carrier bed material interactive circulation. Combustible solid waste fuel is pyrolyzed in the fluidized bed pyrolysis reactor, and a heat carrier bed material overflows and is sent to thecombustion reactor through a star-shaped return feeder; the heat carrier bed material is heated again by utilizing heat released by pyrolysis oil gas combustion in the combustion reactor; and the heated heat carrier bed material enters the pyrolysis reactor again through a fluidized bed return feeder. Heat generated by combustion is transmitted to a pyrolysis process by utilizing interactive circulation of the heat carrier bed material between the two reactors, so that the problem of non-uniform temperature in reactors caused by heat transfer of conventional reactors is solved; the star-shaped return feeder for pyrolysis material returning achieves a good sealing effect, the fluidized bed material return feeder for combustion material returning avoids high oxidation and deformation of mechanical moving parts, and meanwhile the solid circulation flux can be controlled.

Owner:SOUTHEAST UNIV

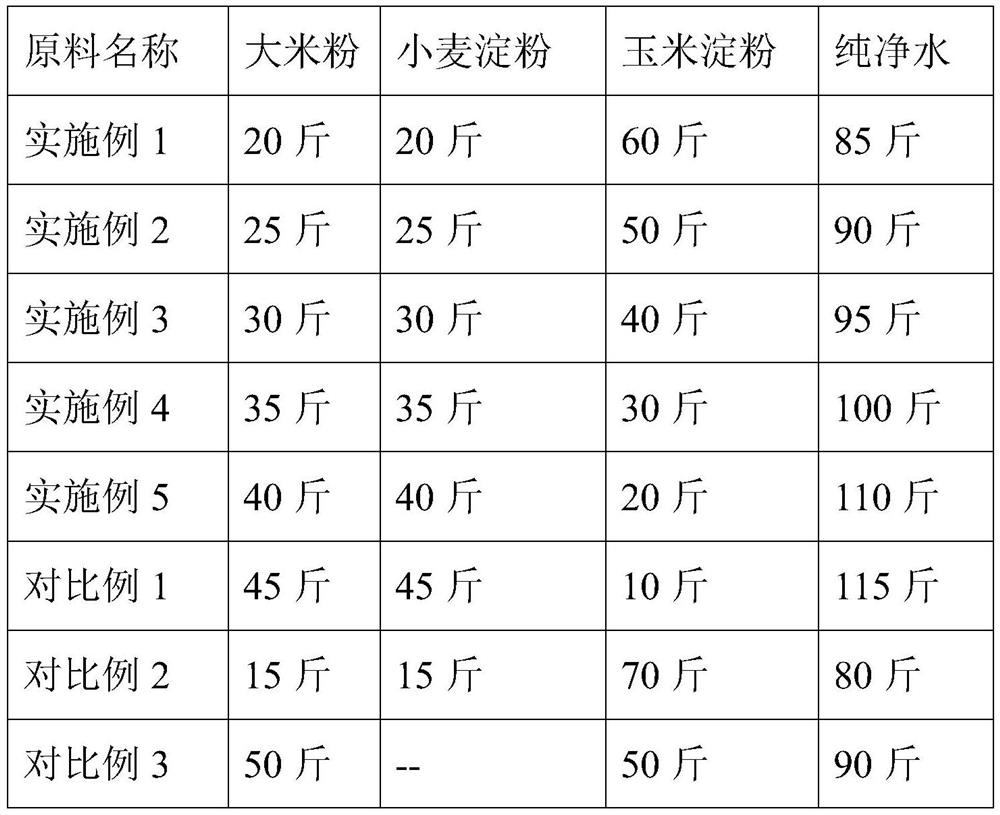

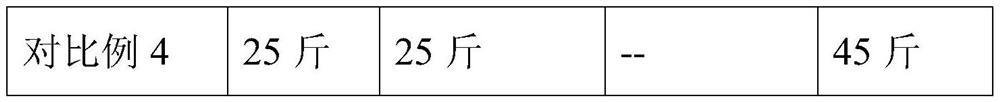

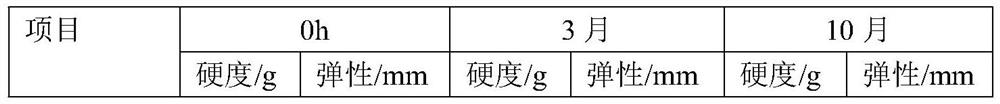

Chewy and elastic fresh-keeping rice noodle and preparation method thereof

ActiveCN113995086AExtended shelf lifeIncrease elasticityClimate change adaptationFood preservationFreeze-dryingPreservative

The invention belongs to the technical field of rice noodle manufacturing, and particularly relates to chewy and elastic fresh-keeping rice noodle and a preparation method thereof. The chewy and elastic fresh-keeping rice noodle is prepared from, by weight, 20-40 parts of rice powder, 20-40 parts of wheat starch, 20-60 parts of corn starch and 85-110 parts of purified water. The preparation method comprises the steps: taking rice powder, wheat starch, corn starch and purified water, preparing into slurry, preparing vermicelli by steam heating, then freeze-drying the vermicelli, unfreezing the vermicelli by microwave-ultrasonic waves, and packaging the vermicelli into bags by using sterile vacuum packaging bags and deoxidized bags. According to the invention, the rice noodles are long in shelf life and free of preservatives, and the stored rice noodles still have good elasticity, are small in cooking loss and are not prone to being burnt in soup or broken.

Owner:贵州黔酸王食品有限公司

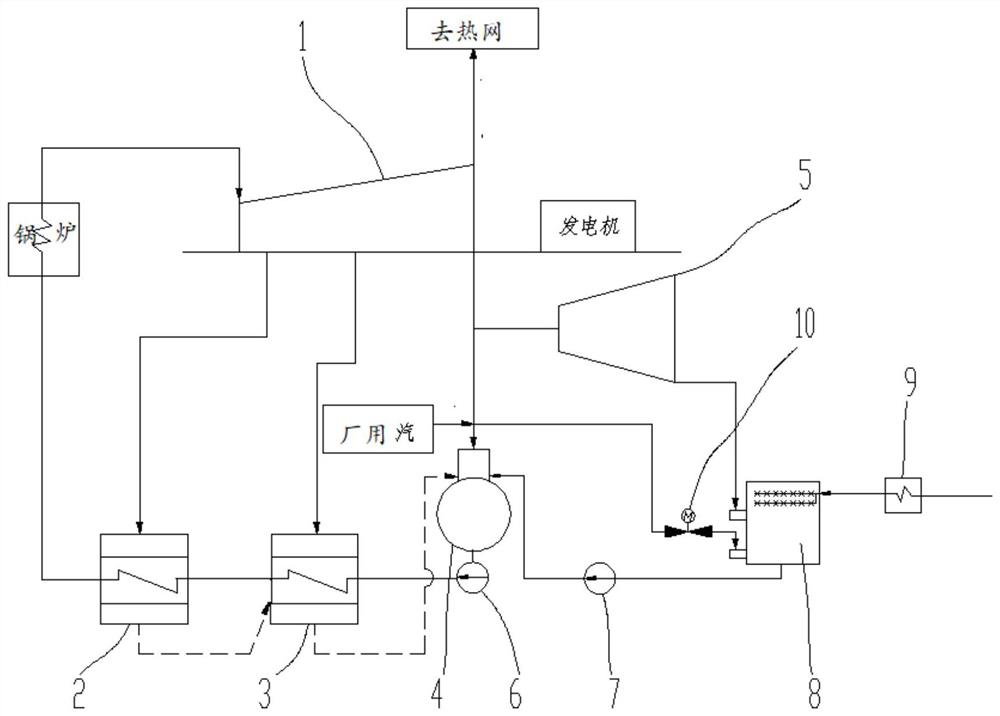

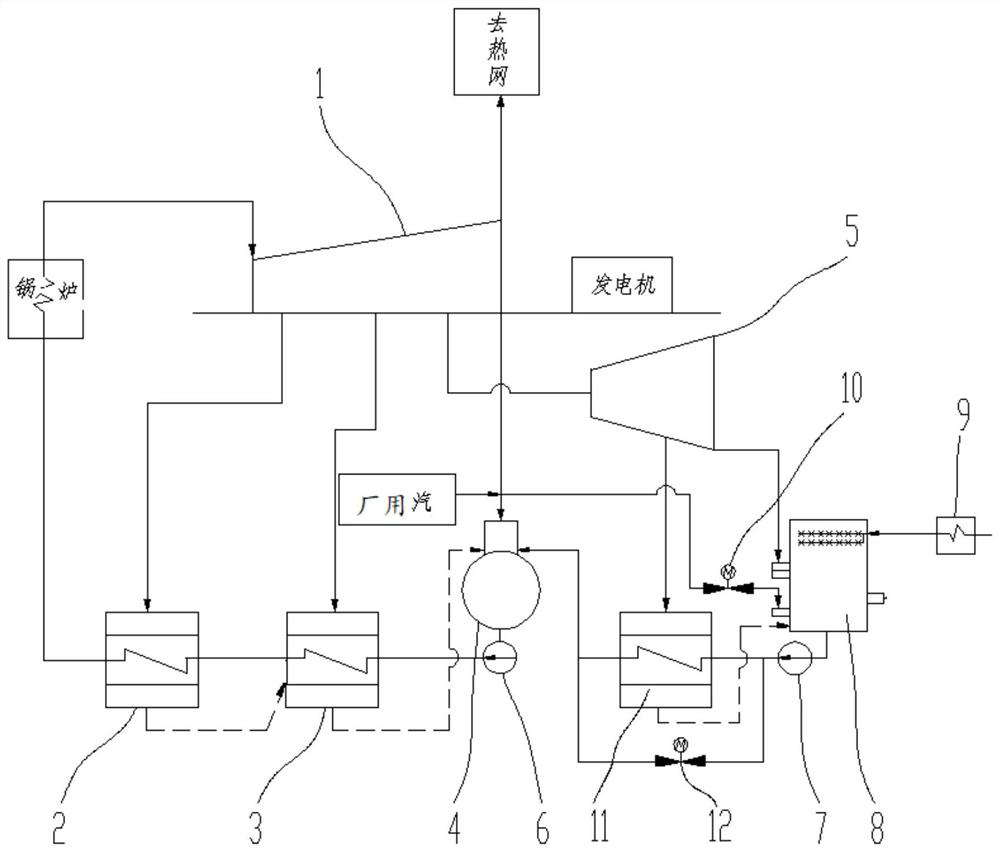

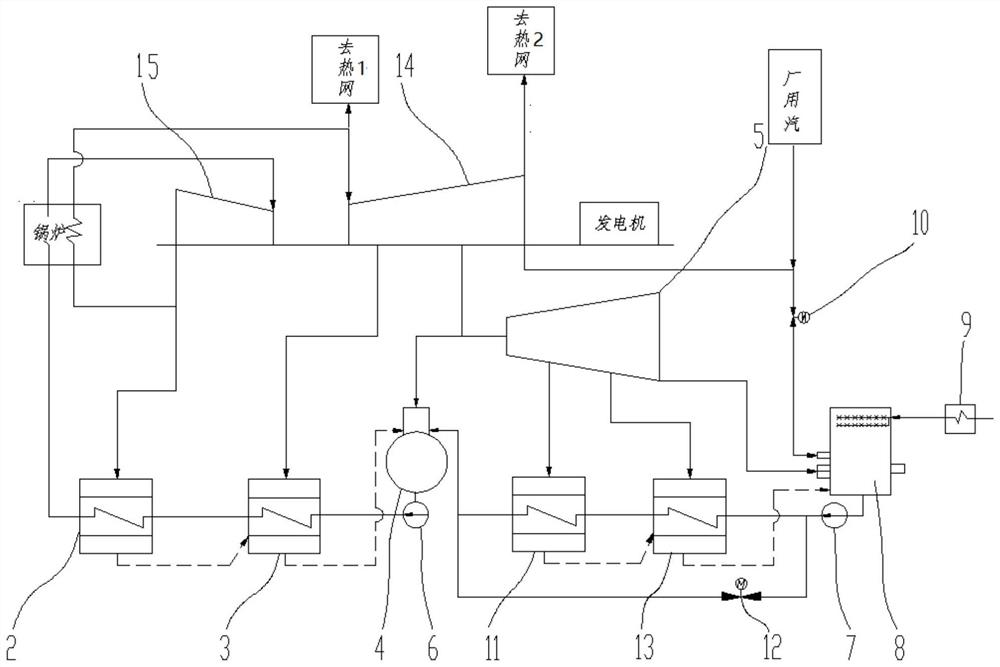

Backpressure steam turbine regenerative system with small steam turbine and design method of thermodynamic equilibrium

PendingCN113294217AChange powerChange trafficLiquid degasificationSteam engine plantsProcess engineeringRegenerative system

The invention discloses a backpressure steam turbine regenerative system with a small steam turbine and a design method of thermodynamic equilibrium of the backpressure type steam turbine regenerative system. The backpressure type steam turbine regenerative system at least comprises a backpressure type steam turbine, an auxiliary device which is connected with the backpressure type steam turbine and used for heating and deoxidizing supplemented water and returned water of the regenerative system, a water supply power device used for providing power for the supplemented water and the returned water of the system to enable the the supplemented water and the returned water to circularly flow in the regenerative system, the small steam turbine connected with the back pressure type steam turbine and used for driving the water supply power device, and a condenser connected with the small steam turbine. The condenser serves as steam exhaust condensing equipment of the small steam turbine and further serves as primary deoxidizing and heating equipment of the the supplemented water and the returned water of the whole regenerative system, steam exhaust of the small steam turbine serves as a deoxidizing steam source of the steam condenser and is completely used for deoxidizing and heating the supplemented water and the returned water of the system, the heat exchange temperature difference is reduced, no cold end loss exists, and the system efficiency is improved.

Owner:DONGFANG TURBINE CO LTD

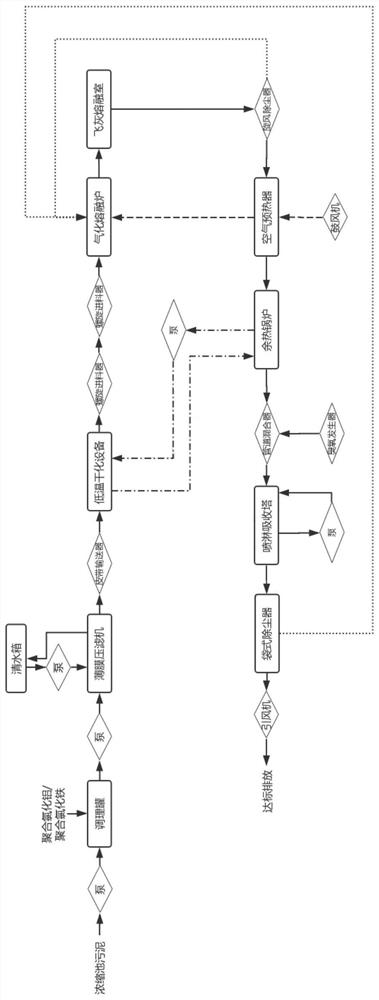

Sludge treatment process

PendingCN111995213AAvoid it happening againReduce usageSludge treatment by de-watering/drying/thickeningDispersed particle separationAir preheaterSludge cake

The invention provides a sludge treatment process. The sludge treatment process comprises the following steps of: pumping sludge in a sludge concentration tank into a sludge conditioning tank for stirring and conditioning to obtain pretreated sludge; pumping the pretreated sludge into a membrane filter press, and extruding and dehydrating the sludge to obtain a sludge cake; conveying the mud caketo low-temperature drying equipment for drying treatment; enabling the filter cake to enter a gasification melting furnace to be gasified and molten to obtain molten slag and first pretreated flue gas, discharging the molten slag after water quenching, and purifying the first pretreated flue gas through a cyclone dust collector and then cooling the first pretreated flue gas through an air preheater and a waste heat boiler; enabling the cooled first pretreated flue gas to enter a gas mixer, and adding ozone into the gas mixer for a mixed oxidation reaction to obtain second pretreated flue gas;feeding the second pretreated flue gas into a spray absorption tower, and absorbing nitrogen and sulfur oxides in the second pretreated flue gas through alkali liquor so as to realize desulfurizationand denitrification; and purifying the second pretreated flue gas discharged from the spray absorption tower through a bag type dust collector, and then discharging the purified flue gas.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Laminating equipment

ActiveCN113264409BSimple structureReduce the difficulty of operation controlFinal product manufactureSecondary cells manufactureCell fabricationMechanical engineering

Owner:SHENZHEN YUCHEN AUTOMATION EQUIP CO LTD

A packaging box with 3D effect and its production method

ActiveCN105015901BNo pollutionLow costCoverings/external coatingsOther printing apparatus3d patterningComposite material

The invention discloses a packaging box with a 3D effect and a production method thereof. According to the packaging box with the 3D effect, a color layer is coated with a light oil layer, pearl powder is arranged in the light oil layer and distributed in a preset rule, the distribution of the pearl powder is changed through press-printing of a 3D pattern plate, and therefore a pattern with a 3D effect is formed. All materials needed by production are degradable print materials and cannot pollute the environment. Meanwhile, raster sheets for attaching are not needed, cost is reduced, operation control difficulty is lowered, and the packaging box has good market application and popularization prospects.

Owner:江西丰彩丽印刷包装有限公司

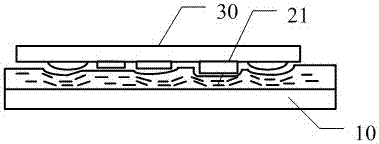

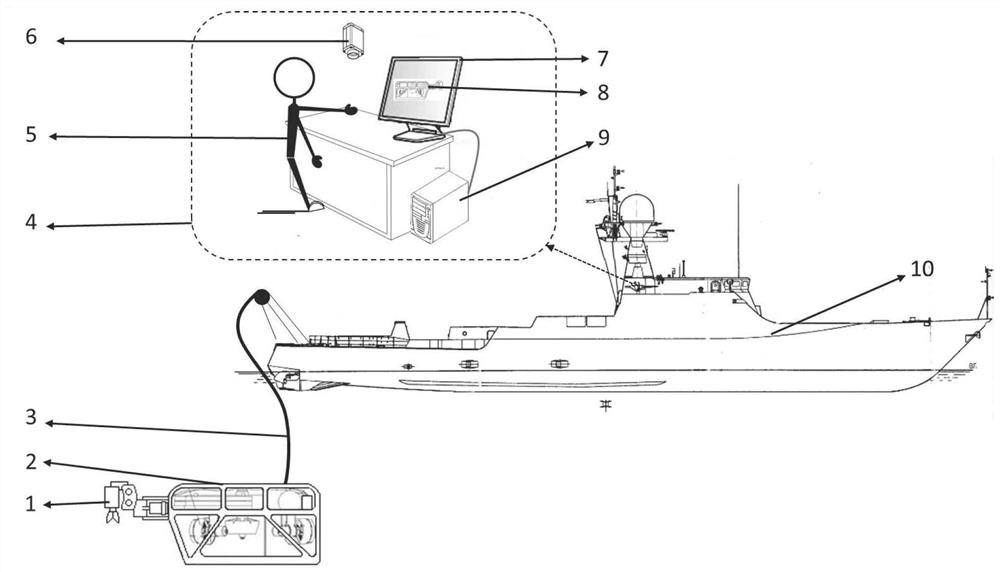

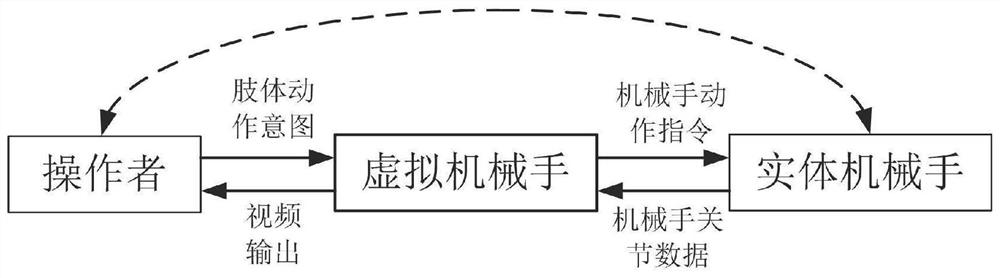

Virtual-real combination and man-machine interaction underwater remote control robot manipulator operation system and method

PendingCN113146612AHighlight substantiveEasy to operateProgramme-controlled manipulatorTeleoperated robotRemote control

The invention provides virtual-real combination and man-machine interaction underwater remote control robot manipulator operation system and method. The system comprises a mother ship, a computer, a display, a three-dimensional somatosensory camera, an underwater robot, a manipulator and an umbilical cable. A virtual manipulator which is completely the same as the underwater entity manipulator is constructed and displayed on a screen, the three-dimensional somatosensory camera is used for capturing limb actions of arms and hands of an operator, the action intention is reflected to the virtual manipulator on the screen, the virtual manipulator is caused to stretch back and forth, move left and right and grasp, and the joint angle of the virtual manipulator is caused to change. The steps from the second step to the fourth step are continuously repeated till the operation task is completed. According to the underwater remote control robot manipulator operation method, the operation difficulty of the operator is reduced, the operation efficiency and the operation precision are improved, and the operation method has obvious advantages compared with an original method.

Owner:SHANGHAI UNIV

Data-driven modeling furnace temperature control method applied to rotary kiln for hazardous waste incineration

ActiveCN109189120BReduce the difficulty of operation controlRealize automatic optimal controlTemperatue controlFurnace temperatureThermodynamics

The invention relates to a data-driven modeling furnace temperature control method applied to a hazardous waste incineration rotary kiln, comprising S1: sampling and detecting basic physical property data of hazardous waste to be treated to obtain a database of basic physical properties of hazardous waste; S2: using an incinerator DCS system Collect the operating data of the rotary kiln; S3: According to the operating data of the rotary kiln and the database of the basic physical properties of hazardous waste, the autoregressive sliding average modeling method is used to establish the temperature fitting prediction model of the rotary kiln; S4: according to the temperature fitting prediction model of the rotary kiln The temperature change during operation is predicted and the corrected value of the control parameter is proposed according to the predicted temperature; S5: According to the corrected control parameter, the rotary kiln is adaptively controlled in real time, and the rotary kiln runs automatically and smoothly. The invention realizes the automatic optimal control of the whole process of feeding the rotary kiln, supporting combustion, supplementing air, and adjusting the rotating speed, and is of great help in improving the economic benefits of the rotary kiln for hazardous waste disposal.

Owner:FUZHOU UNIV

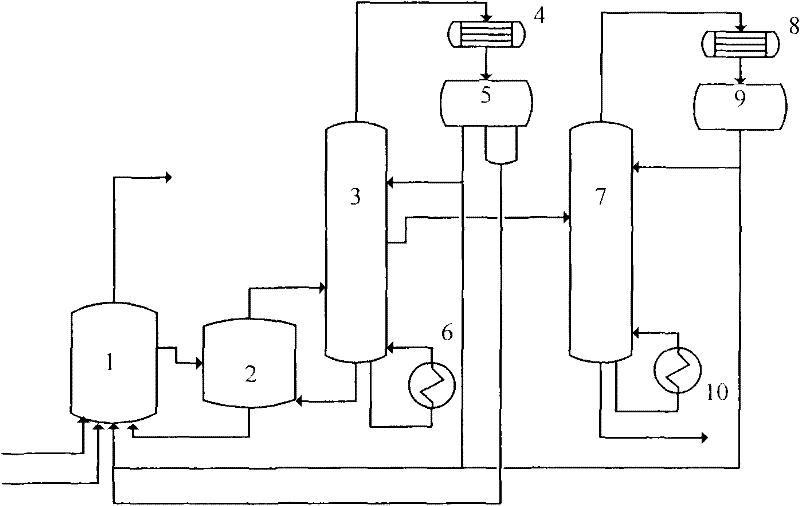

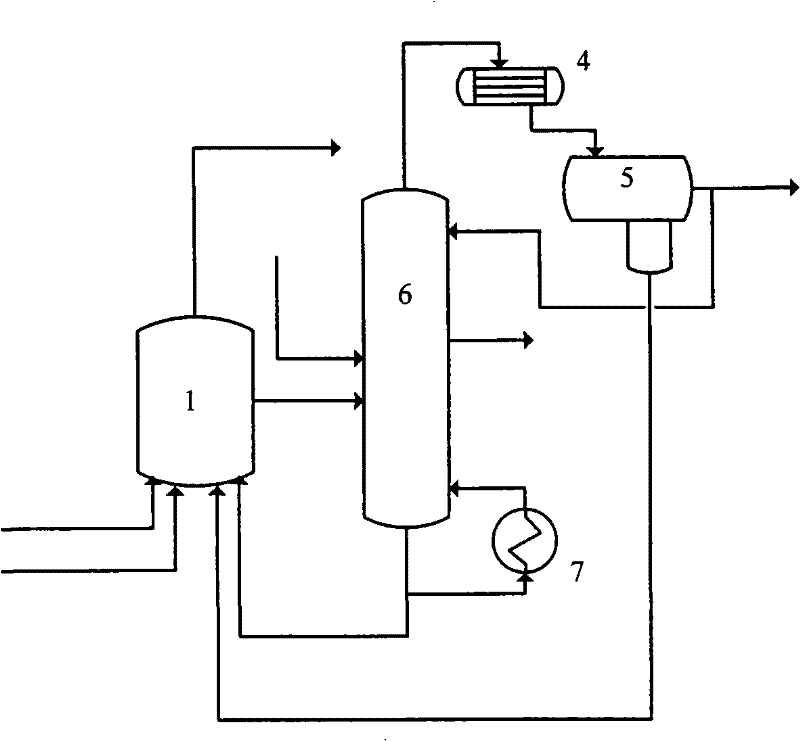

Method for synthesizing acetic acid through low-pressure methanol carbonylation and device thereof

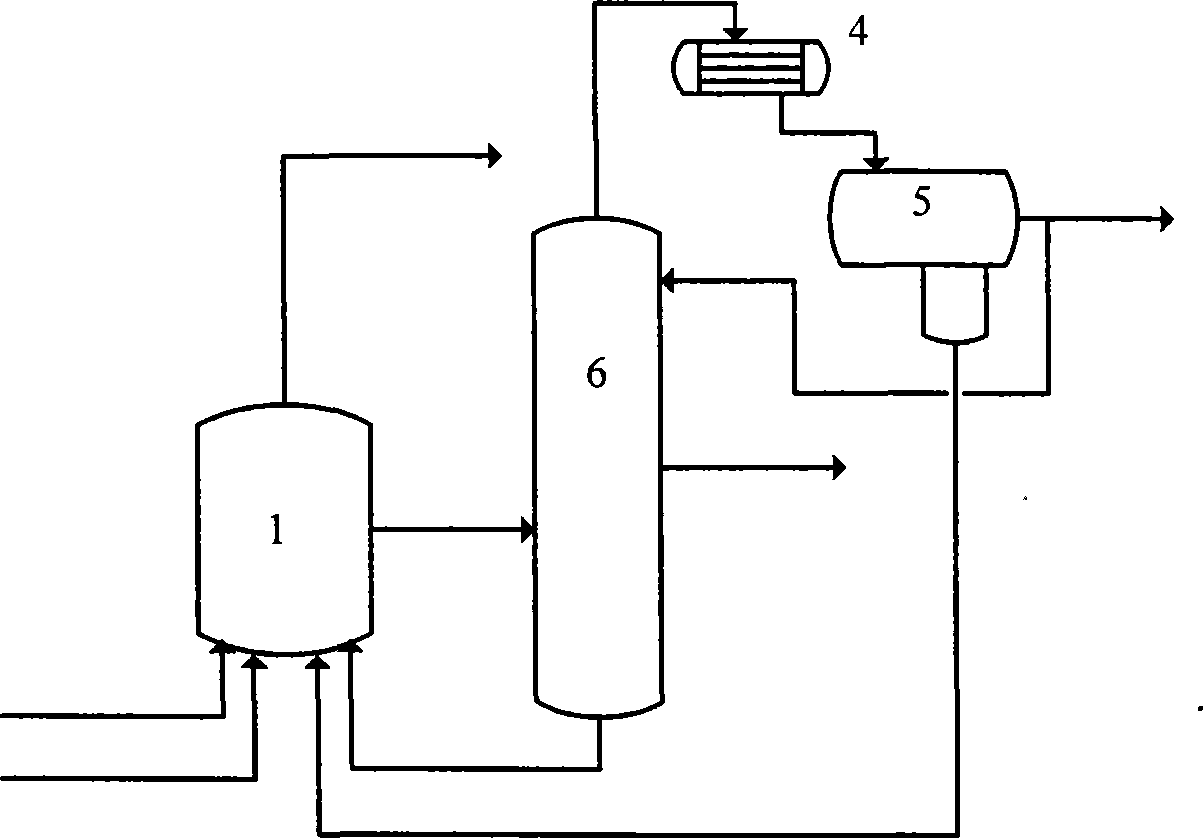

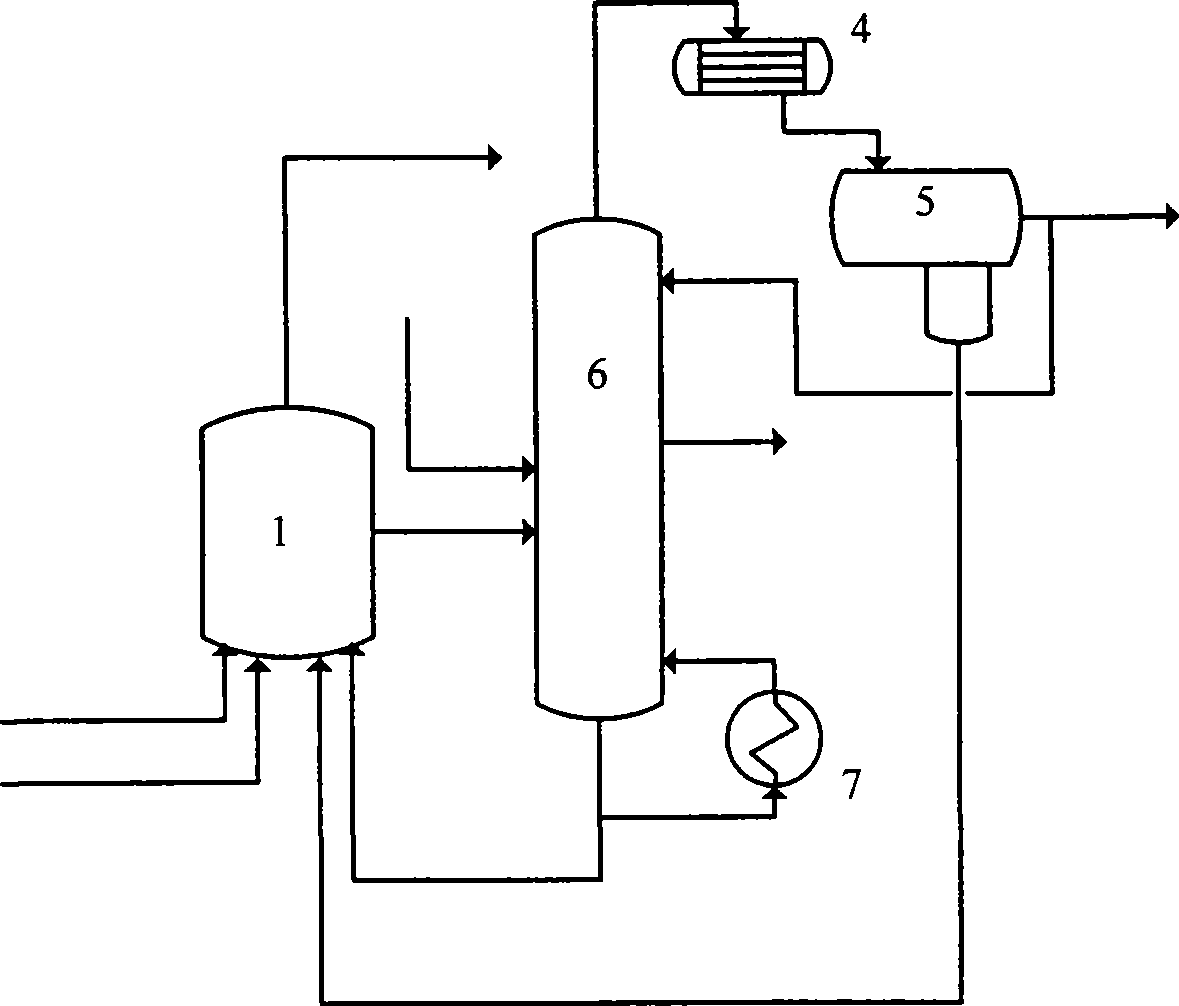

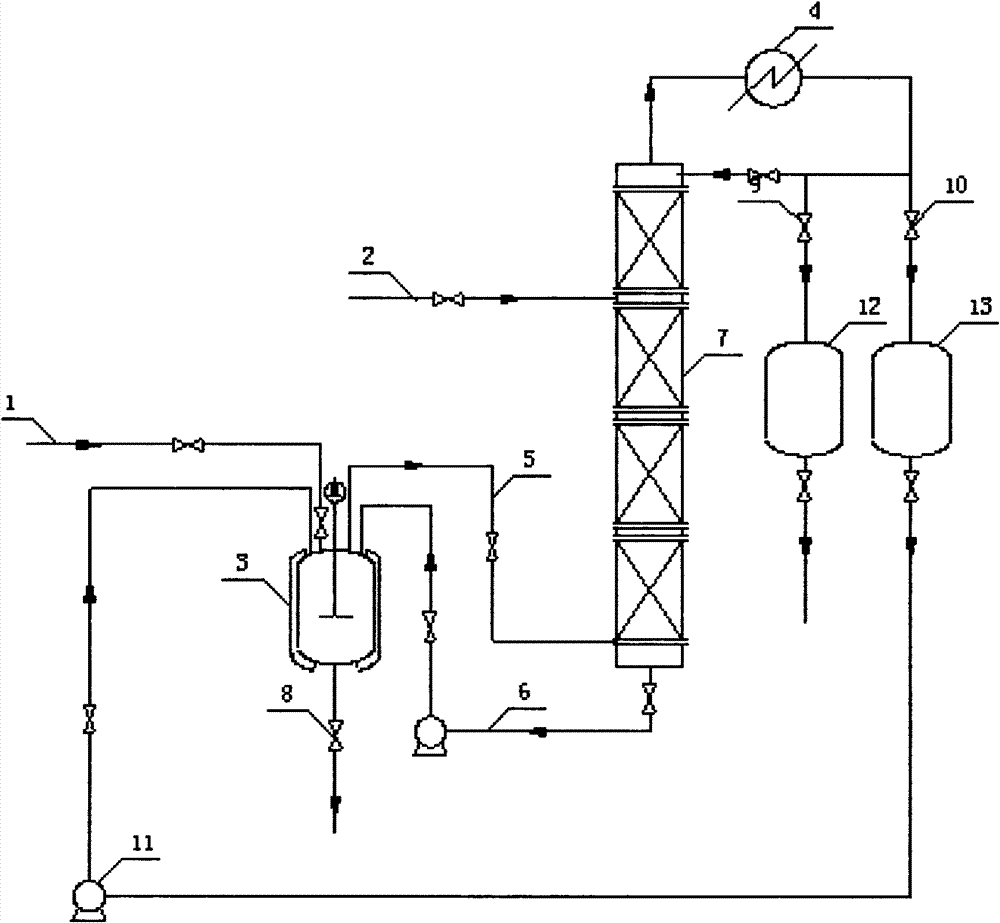

ActiveCN101665424BAchieve recyclingReduce return routeCarboxylic preparation from carbon monoxide reactionChemical recyclingAcetic acidGas phase

The invention relates to a method for synthesizing acetic acid through low-pressure methanol carbonylation and a device thereof, belonging to the field of chemical technology. The invention comprises the following steps: firstly, carrying out reaction between methanol and carbon monoxide in a reactor containing a reaction solution so as to generate the acetic acid; feeding the reaction solution into a catalyst recovery tower to recover a catalyst through flash vaporization and washing; feeding flash vaporization gas phase into a rectifying tower, and obtaining finished acetic acid through rectification; condensing fractions of the top of the rectifying tower and then dividing the fractions into light phase and heavy phase, wherein a part of the light phase flows back to the upper part of the rectifying tower, and the remnant light phase and heavy phase flow back to the reactor to continuously take part in reaction. In the invention, the prior functions executed by a lightness-removingtower and a dehydrating tower are merged to be completed in the rectifying tower so that the process route of acetic acid preparation is simplified, the equipment investment of the device is reduced,the difficulty of operation control is reduced at the same time, consumption of the device can be effectively reduced, and the production cost is reduced.

Owner:BEIJING ZEHUA CHEM ENG

Suspended pattern packaging box and processing method thereof

ActiveCN103587791BReduce the difficulty of operation controlNo pollutionCoverings/external coatingsGratingPrinting ink

The invention discloses a suspended pattern packaging box and a processing method thereof, wherein, the box body of the suspended pattern packaging box is printed with a bottom pattern layer and a suspension effect layer arranged on the bottom pattern layer; the bottom pattern layer The pattern on the surface is a plane pattern; the suspension effect layer includes an arrayed bead grating formed by mixing transparent microbeads in UV varnish. Compared with the existing technology, the design of the packaging box can be printed directly on the packaging box body according to the needs, without the need for wrong screen printing, which greatly saves time; at the same time, the materials required for production are all degradable printing materials, which will not Pollution to the environment is caused; in addition, there is no need to use transparent resin ink as a printing material, which saves costs.

Owner:SHENZHEN JINJIA GRP +1

Reactive distillation device and method for separating and purifying methylal

InactiveCN102068945BImprove conversion rateReduce the difficulty of separationOrganic chemistryOrganic compound preparationRefluxReactive distillation

The invention relates to a reactive distillation device and method for separating and purifying methylal. The device mainly comprises a reactor / agitator, a distillation column, a condenser, a reflux ratio controller, stainless steel fillers, a temperature gauge, a pressure gauge and a product collection and storage tank. The methylal is synthesized by subjecting the raw materials including methanol and formaldehyde to react and is separated and purified. After the methylal product is extracted, the distillation column is continuously used for separating and recovering the methanol and is usedfor the next cycle, thus improving the utilization ratio of the raw materials. The methanol is added to the reactor by one step. The problem that the product purity fails to meet the requirement due to azeotropy of the methanol and the methylal can be solved through the operation mode of feeding the formaldehyde from the top of the distillation column. The concentration of the formaldehyde in theresidual liquid in the reactor conforms to the effluent standard. Through the operation mode of carrying out reaction and separation separately, the adverse effects of difficult control and difficultfilling of catalysts caused by inconsistence of the reaction conditions and the separation conditions can be overcome and the operation difficulty of reactive distillation can be reduced, thus expanding the application range of reactive distillation.

Owner:TIANJIN UNIV

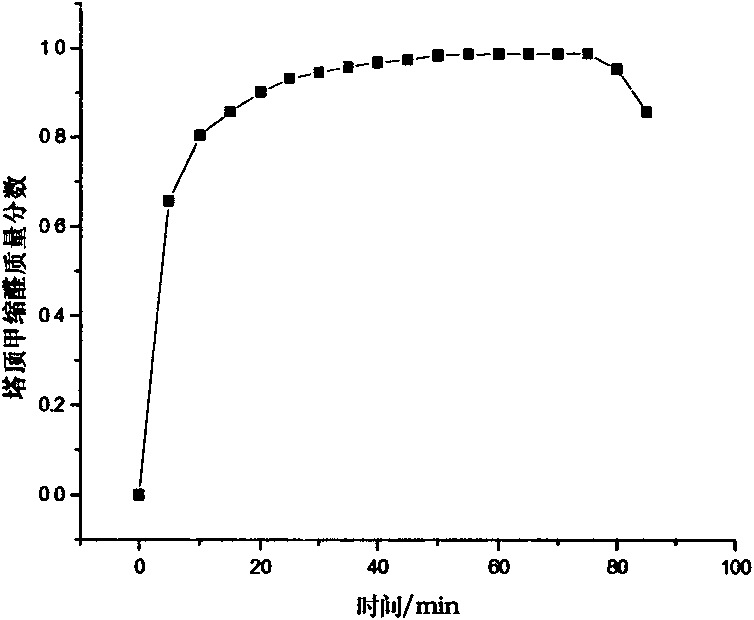

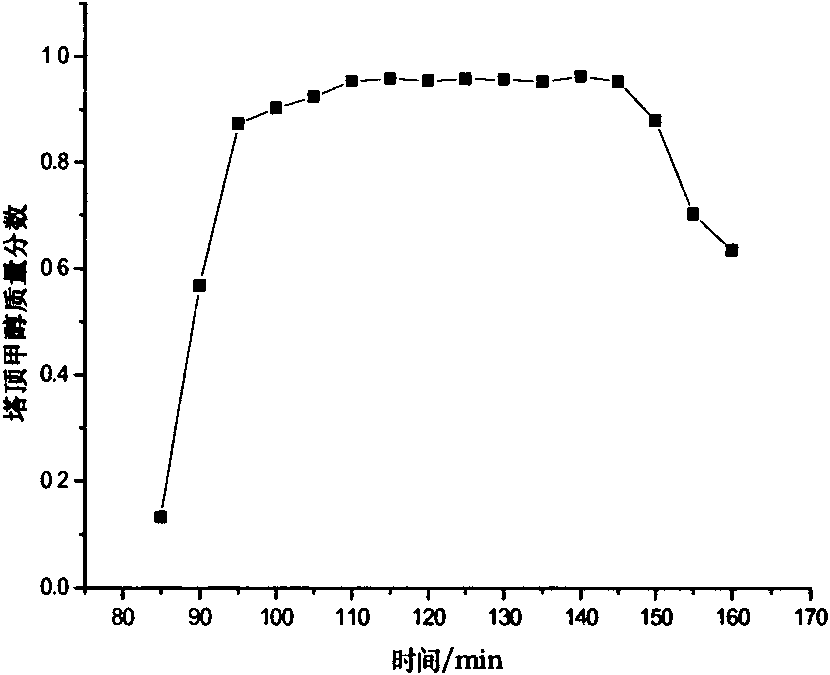

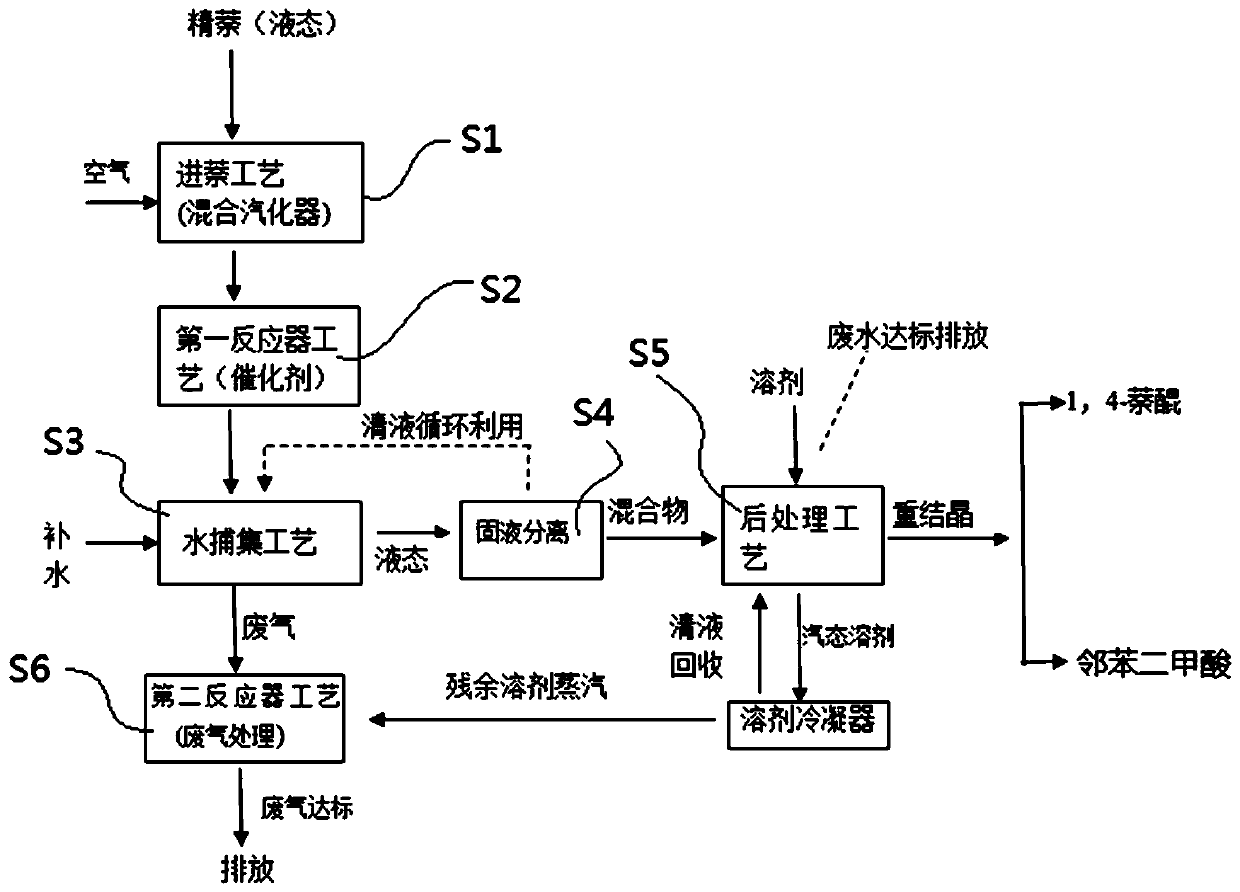

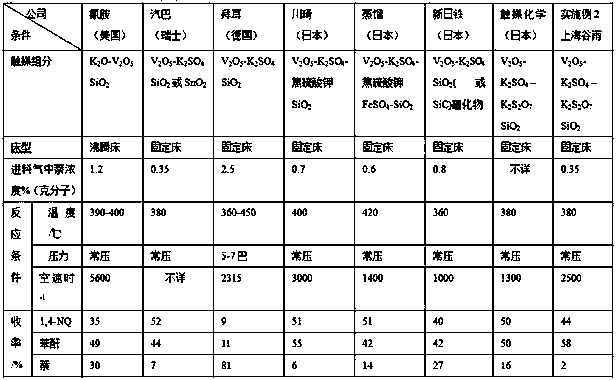

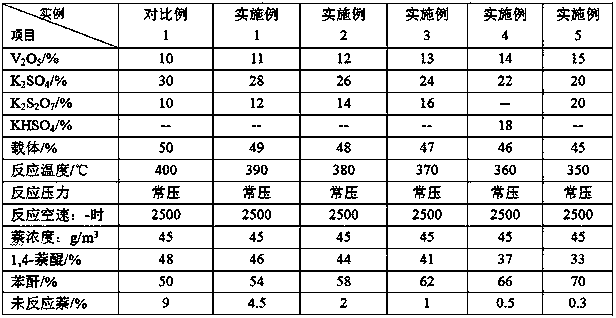

A kind of production method of 1,4-naphthoquinone, adopted catalyst and its application

ActiveCN109896947BReduce the difficulty of operation controlImprove securityQuinone preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsTrappingCatalytic oxidation

The invention discloses a production method of 1,4-naphthoquinone, the catalyst used and its application. The method comprises: step 1, mixing liquid naphthalene with hot air, heating and vaporizing to obtain a naphthalene-air mixture; step 2 , the naphthalene-air mixture is input into the first reactor, and the catalytic oxidation reaction is carried out at 350-400°C by the first catalyst, and the gas residence time is 1-1.5 seconds; The aqueous solution of the product; Step 4, performing solid-liquid separation treatment, collecting the solid mixture and the liquid mixture respectively; Step 5, separating the solid mixture through solvent extraction and recrystallization to obtain 1,4-naphthoquinone. The production method of the present invention has low difficulty in controlling the concentration of naphthalene, high safety, low degree of deep oxidation, and high yield. The conversion rate of naphthalene is 95.5~99.7%, and the yields of the main reaction products 1,4-naphthoquinone and phthalic anhydride are 44% respectively. ~58%, total reaction yield ≥ 102%, total product yield ≥ 95%, broad application prospects.

Owner:上海谷雨医药科技有限公司

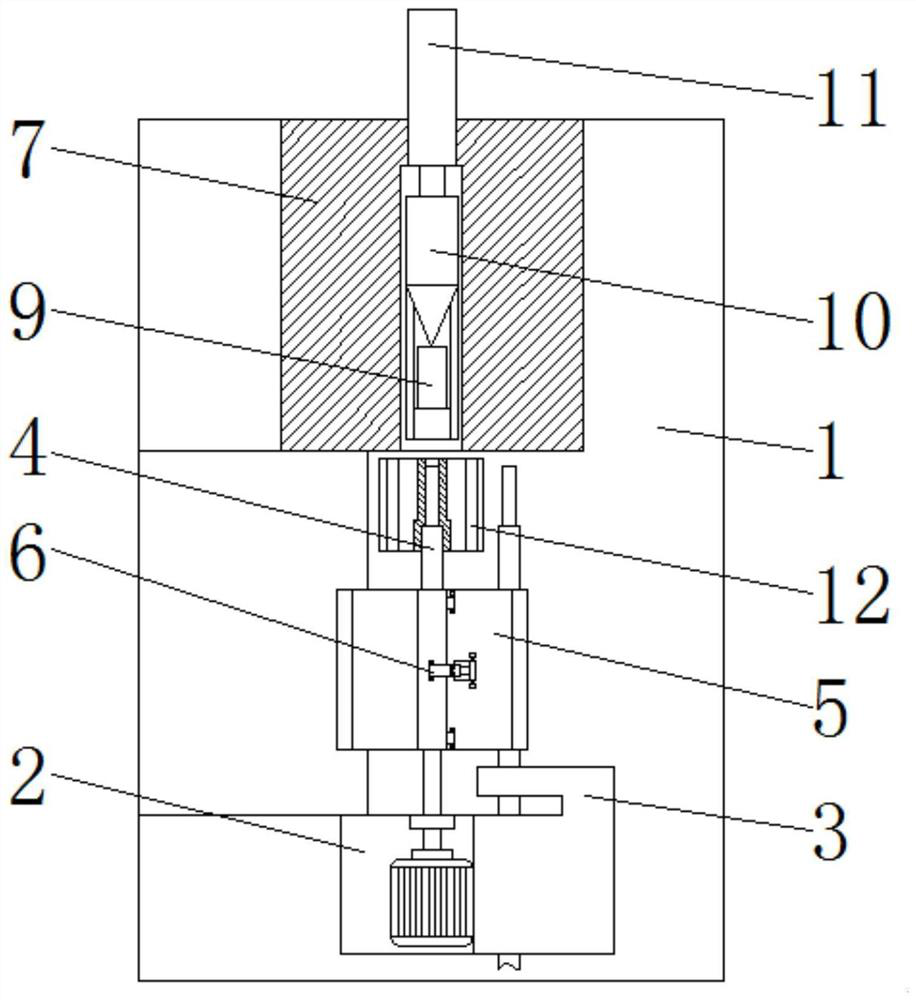

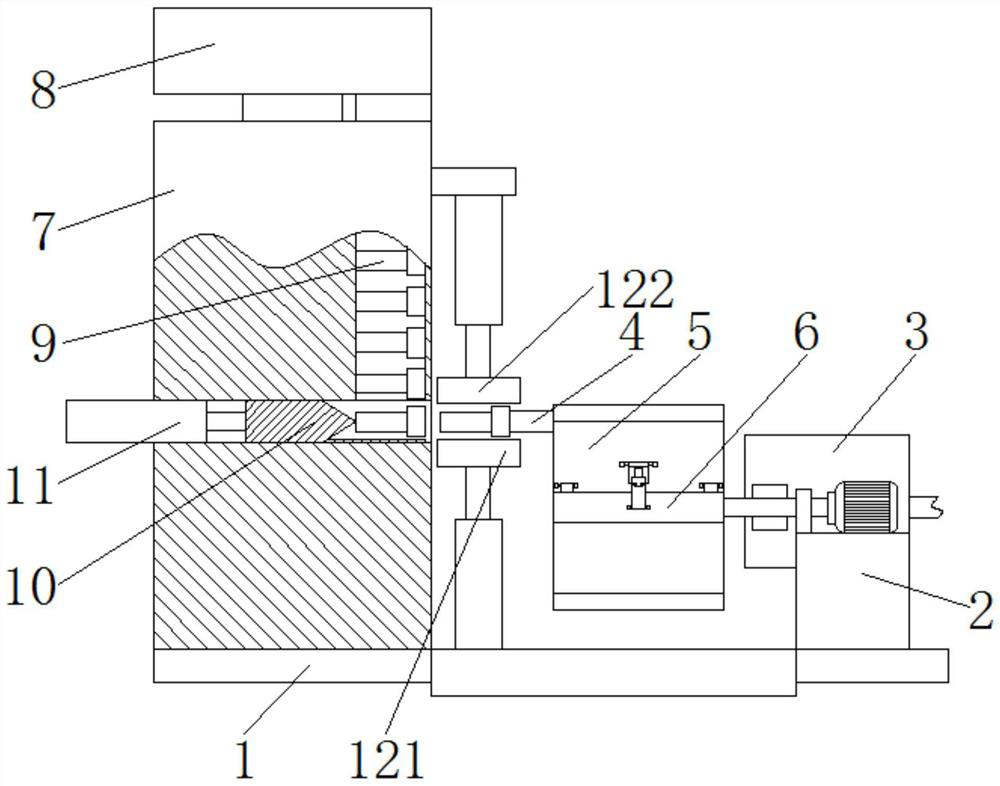

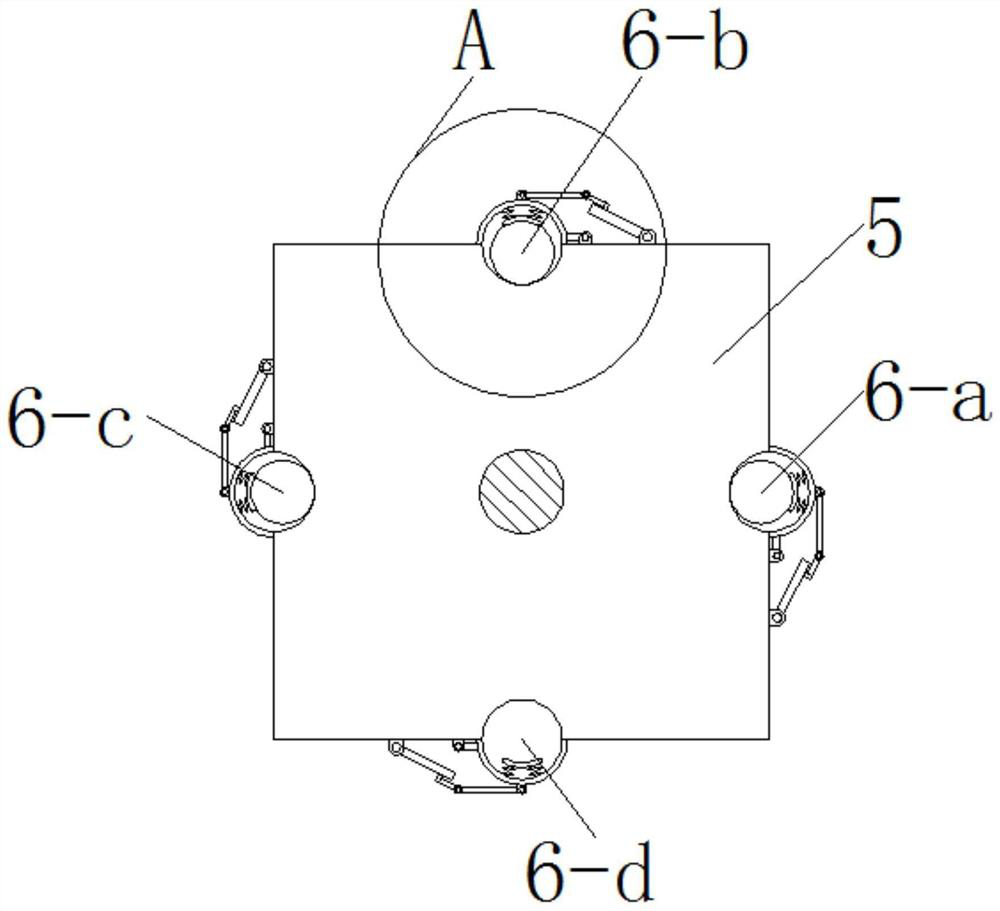

An automatic crimping machine for electronic components

ActiveCN111293567BAvoid displacementReduce the probability of insufficient fixationConnection formation by deformationElectronic componentIndustrial engineering

The invention relates to the technical field of electronic component crimping equipment, and discloses an automatic crimping machine for electronic components. The automatic crimping machine comprisesa base, wherein a fixed seat is fixedly mounted at the front part of the upper surface of the base, and a cable processing device is fixedly mounted at the top of the right side of the fixed seat. The processing process of a wire is divided into four areas through the arrangement of a square rotating body and a fixing device, so that the cutting, peeling and crimping of the connecting terminal and the releasing process of the wire can be simultaneously performed, and the production efficiency of the crimping machine is greatly improved. In addition, the equipment operation control difficultyis reduced through the fixed rotation angle, the positioning accuracy between the wire and the connecting terminal is improved, and the product production quality is improved. Meanwhile, the wire is fixed by the fixing device, the wire is prevented from moving when the connecting terminal is fixed by sleeving and stamping, the wire is further prevented from being inserted into the connecting terminal too deeply or too shallowly, and the probability of insufficient fixation of the connecting terminal is reduced.

Owner:贵州芯火悦创科技有限公司

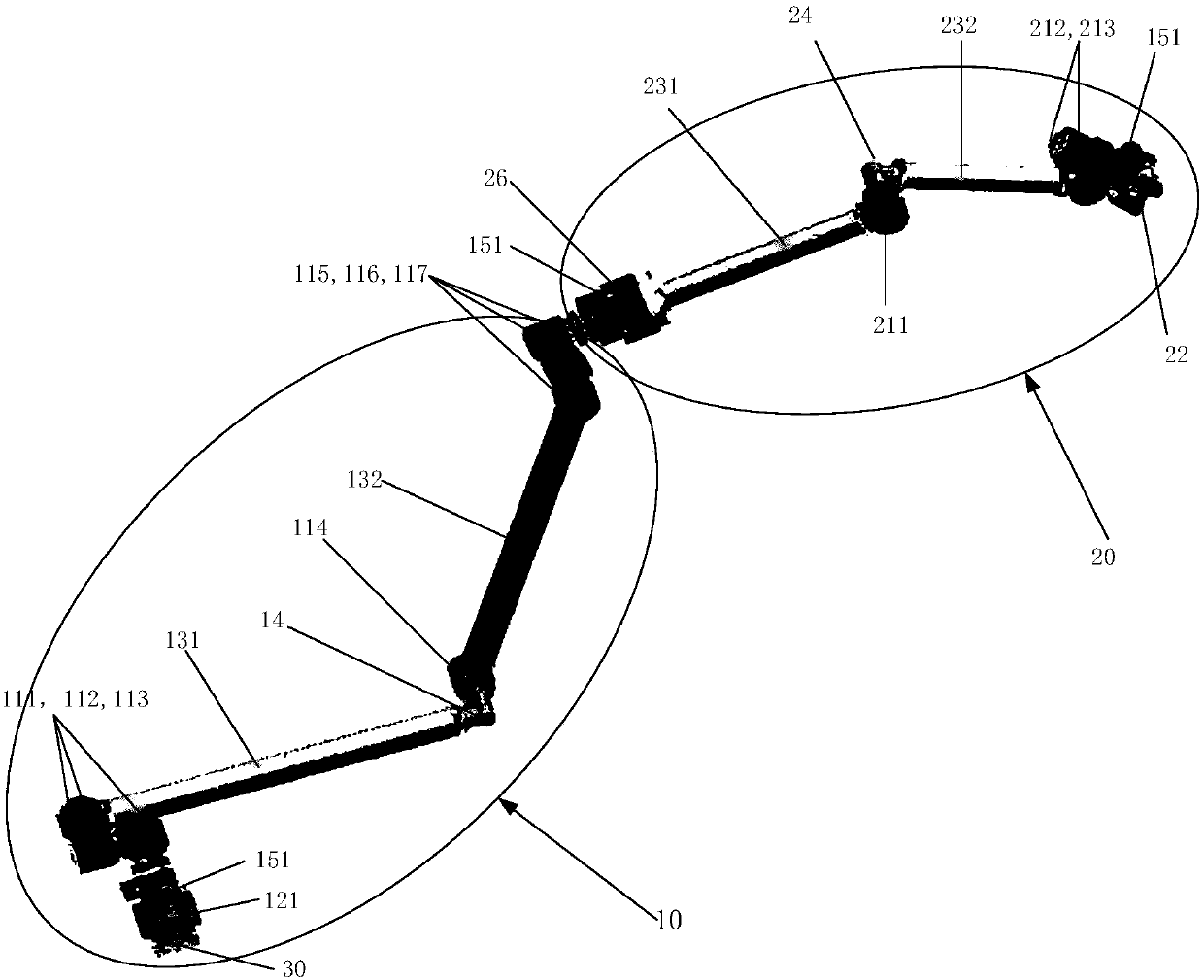

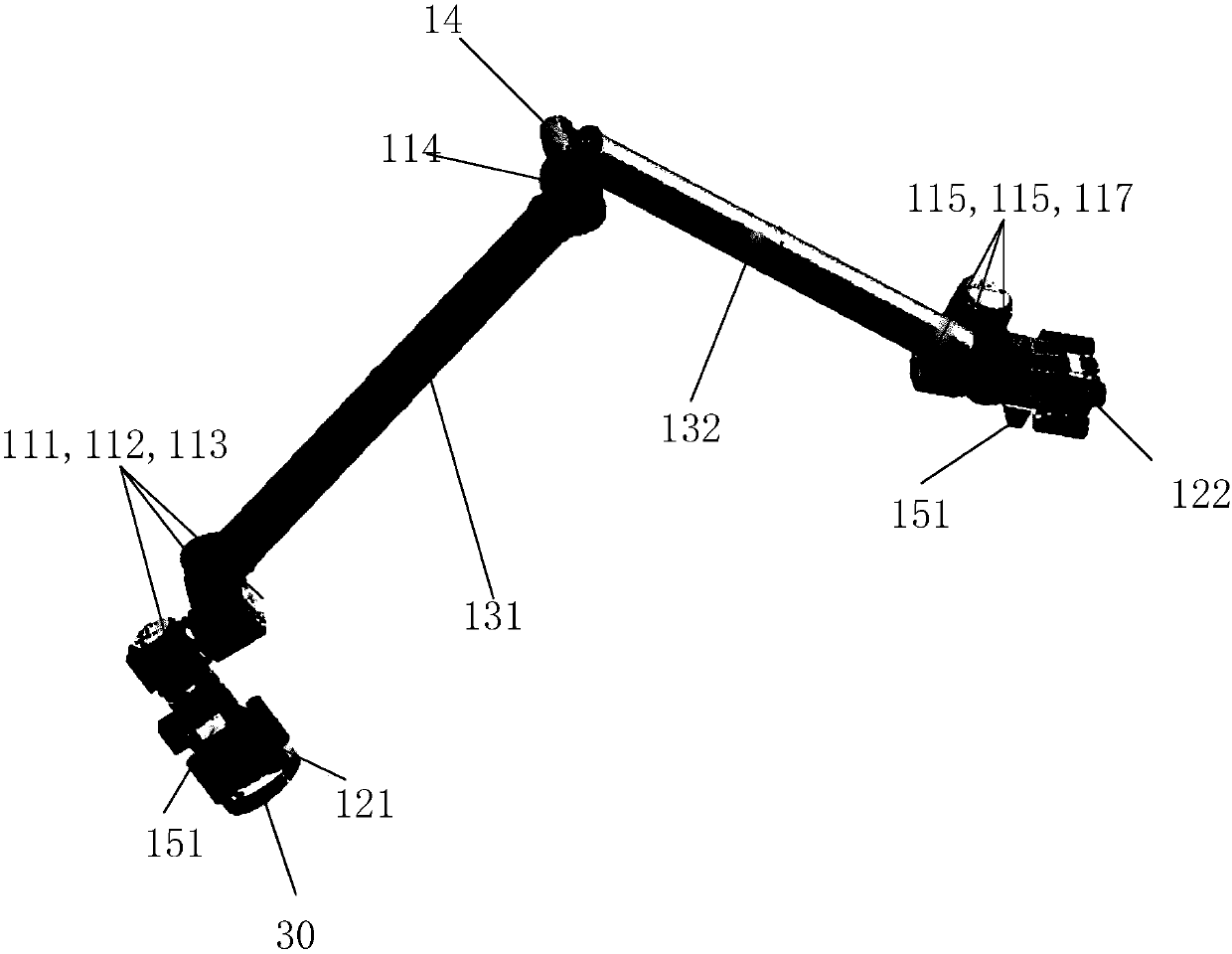

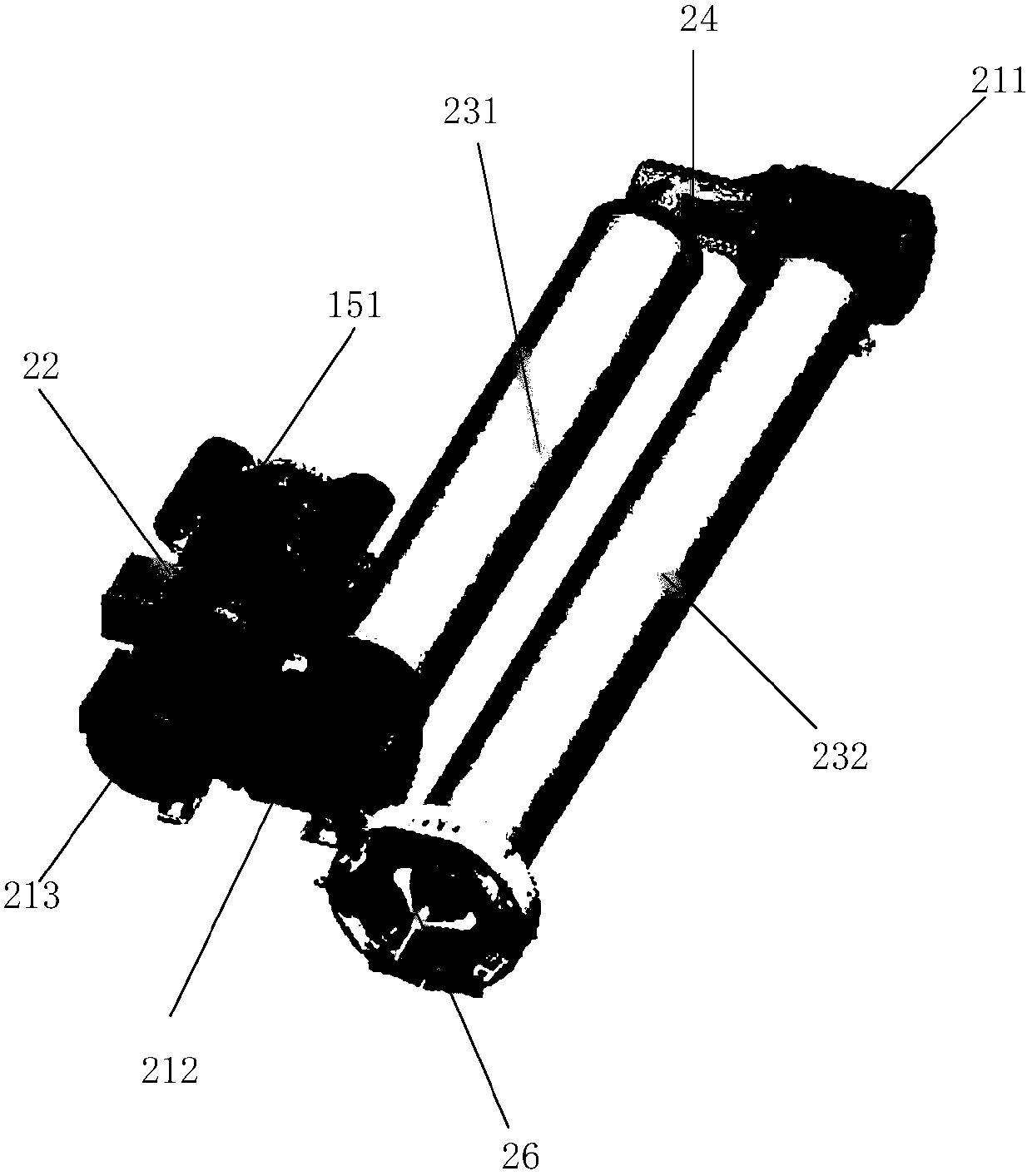

A space super-redundant drive manipulator and assembly method

ActiveCN106002948BImplement extended functionsIncreased redundant operation capabilityProgramme-controlled manipulatorJointsControl mannerResource utilization

The invention discloses a spatial hyper-redundant drive manipulator. According to the spatial hyper-redundant drive manipulator, the manipulator extension function is realized in the form of cascade connection between a main manipulator and an auxiliary manipulator; meanwhile, the manipulator redundant operating capability is greatly improved; the realization form is relatively simple and reliable; and the operating functions and the operating performance of the original manipulator are not influenced. According to an on-orbit assembling method of the spatial hyper-redundant drive manipulator, all joints of the main manipulator and the auxiliary manipulator can be uniformly planned and controlled by a central controller of the main manipulator; such a time-sharing control manner that coarse positioning operation is performed at the first 7 degrees of freedom as well as fine positioning operation and the like are performed at the last 6 degrees of freedom can be adopted; compared with 13-degree-of-freedom redundant operation, the time-sharing control manner has the advantage that the operation control difficulty can be greatly reduced under the premise that the operation precision is guaranteed; and meanwhile, the three intermediate joints are shared, so that the space resource utilization ratio is greatly improved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Nitrile hydratase industrial fermentation method

ActiveCN101200702BHigh activityImprove fermentation production cycleEnzymesChemical cell growth stimulationIndustrial fermentationSugar

The present invention provides a nitrile hydratase industrial fermentation production prescription and a fermentation method. The prior nitrile hydratase industrial fermentation base fluid is used asa base, trisodium phosphate is added into the fermentation base fluid and the adding quantity is 0.13 percent to 0.15 percent of the weight of fermentation fluid. The prescription is adopted, after material is put and dissolved, sodium hydroxide is used to adjust the pH value to be 7 to 8; then disinfection is processed; when the temperature rises till 110 DEG C to 120 DEG C, the pressure is keptfor 10 to 20 minutes; subsequently, the temperature of the material in a fermentation tank is reduced to 20 DEG C to 30 DEG C fast; when a strain meets the index, the subcultivation is processed for the fermentation production. The method can improve the activity of the nitrile hydratase by more than 50 percent and synchronously can ensure that the fermentation production period of the fermentation tank is shortened by one third, which does not require adding new devices and is simple for carrying out; compared with the feeding methods of feeding sugar, feeding sodium hydroxide, etc., the method of the present invention reduces additional work and the operation and control difficulty brought by feeding during the course of the fermentation and eliminates the occurrence of the status that the fermentation tank is infected bacteria caused by feeding.

Owner:PETROCHINA CO LTD

Method and apparatus for synthesizing acetic acid by methanol low-voltage carbonylation

ActiveCN101503346BSimplify the process routeShortened return routeCarboxylic preparation from carbon monoxide reactionCarboxylic compound separation/purificationAcetic acidLow voltage

The invention relates to a method for chemically synthesizing acetic acid by using methanol low pressure carbonyl and a device thereof, belonging to the technical field of chemical engineering. The method comprises: methanol and carbon monoxide firstly react in a reactor filled with reaction liquid to generate the acetic acid, and then the reaction liquid enters a multifunctional tower to be processed by flash evaporation and lightness removal to lead overhead fraction of the multifunctional tower to enter a condenser, so that part of light phase in the condensate liquid flows and returns to a lightness removing section of the multifunctional tower, and heavy phase returns to the reactor to continuously take part in the reaction. The method combines the functions of the existing evaporator and lightness removing tower into the multifunctional tower, so as to simplify the flow route of acetic acid preparation, shorten the returning route of catalyst, be beneficial to maintaining the stable property of the catalyst and reducing the loss of the catalyst; the existing evaporator and lightness removing tower are combined into a whole, so that the equipment investment is reduced and thedifficulty of operation and control can be lowered.

Owner:BEIJING ZEHUA CHEM ENG

A method for generating synchronous fixed-frequency current phasors in a full-inverter microgrid

ActiveCN107732976BReduce the difficulty of operation controlFlexible and controllable frequencySingle network parallel feeding arrangementsMicrogridVoltage droop

The invention discloses a generation method of synchronous fixed-frequency current phasors in a full-inverter type microgrid. A GPS satellite timing signal is used as a global synchronous reference signal so as to control the synchronous current phasors, which are constant in output frequency and coincident in phase, of all schedulable distributed power inverters in the microgrid; according to a microgrid distributed power current-voltage droop control strategy, a current amplitude instruction is generated, a complete current phasor reference instruction is obtained with the combination of a phase instruction generated according to the global synchronous reference signal, and the amplitudes of the output current phasors of the schedulable inverters are adjusted, so that the network voltageoperates within a qualified range, and a synchronous fixed-frequency current source microgrid is formed. In the generation method, the advantages that the amplitude, the frequency and the phase of the output voltage (current) of the inverters are flexibly controllable are given full play to, and the control over the operation of the microgrid is simplified into a single voltage control, so that the operation control difficulty of the full-inverter type microgrid is obviously reduced.

Owner:SHANDONG UNIV OF TECH +1

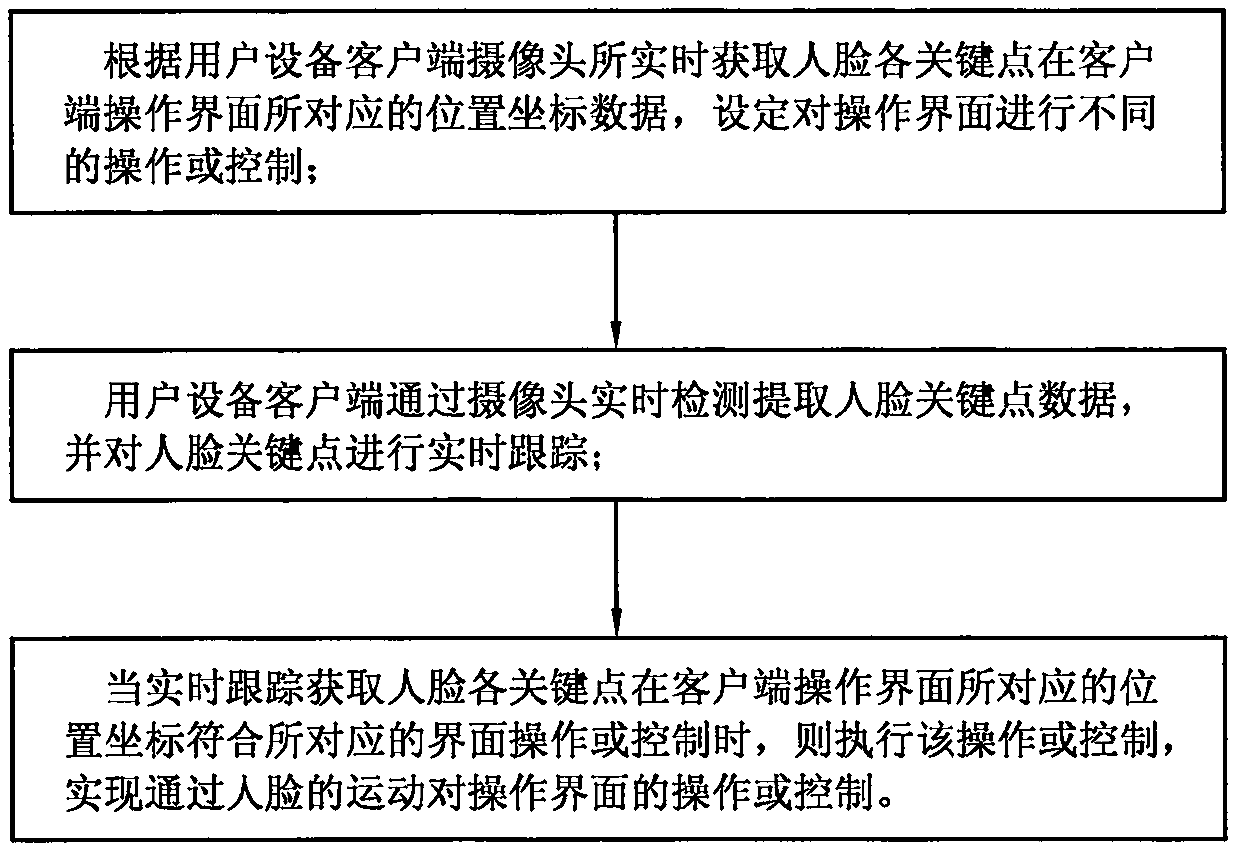

Interaction method based on human face detection tracking and game method

PendingCN109954274AImprove experienceReduce the difficulty of operation controlVideo gamesFace detectionGame interface

The invention provides an interaction method based on human face detection tracking and a game method. According to position coordinate data of each key joint of the human face corresponding to a client operation interface obtained in real time by a client camera of user equipment, different operation and control performed on the operation interface is set; the user equipment client detects the extraction human face key point data through a camera and performs real-time tracking on the human face key points; when the corresponding position coordinate of each key point of the human face obtained through real-time tracking in the client operation interface conforms to the interface operation or control, the operation or control is executed; the operation or control of the human face movementon the client operation interface and the game interface can be realized.

Owner:金德奎

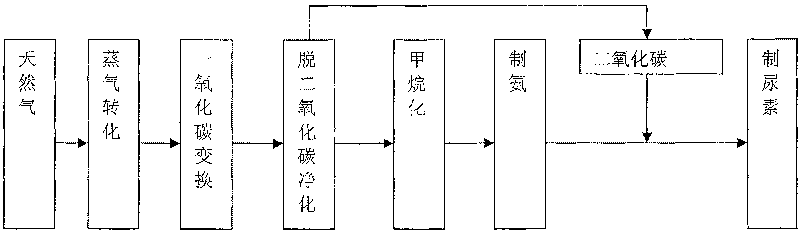

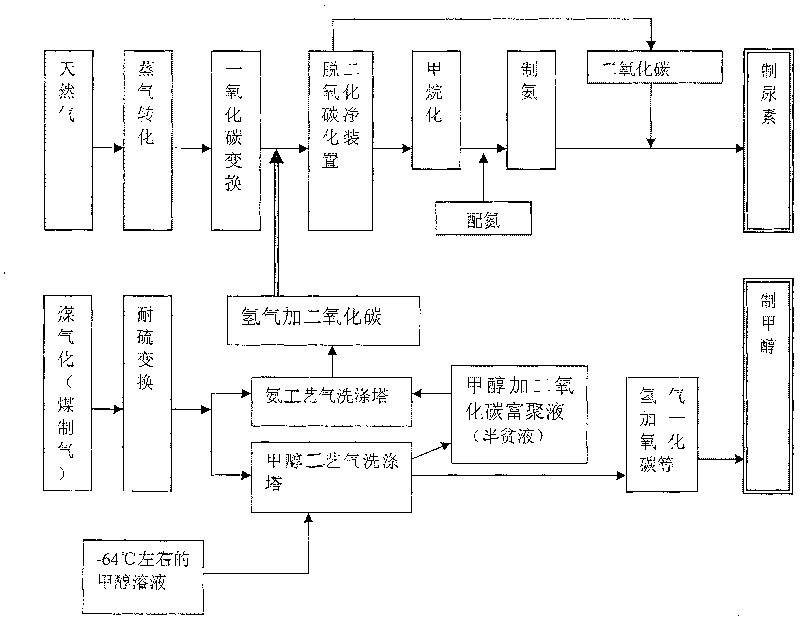

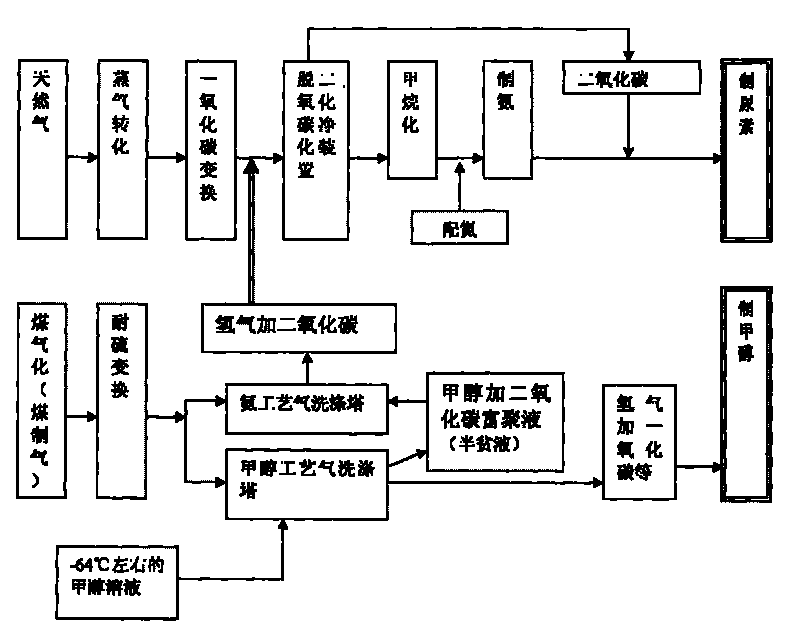

Combined purifying technique for ammonia preparation from natural gas, ammonia preparation from coal and methanol preparation from coal

InactiveCN101214922BAdvantages of combined purification process technologyReduce energy consumptionHydrogen separation using liquid contactGas purification by liquid washingSyngasAmmonia

The combined purification process of ammonia preparation with natural gas and coal as well as methanol preparation with coal belongs to the purification technical field of synthesis gas of ammonia preparation with natural gas and coal as well as methanol preparation with coal. In the low-temperature methanol purification system of the process gas of methanol preparation with coal and ammonia withcoal, the coal gas is fed into the bottom of the coal prepared methanol and coal prepared ammonia process gas scrubber; meanwhile, fresh methanol solution with the temperature of about 64 DEG C belowzero is used to wash only the coal prepared methanol process gas; the semi lean solution is taken out of the coal prepared ammonia process gas scrubber to wash the coal prepared ammonia process gas; the H2+CO2 mixed gas used for synthesising ammonia is taken out from the coal prepared ammonia process gas scrubber and fed in the CO2 purification device of the prior natural gas prepared ammonia process purification system; the follow-up process of the prior natural gas prepared ammonia is used to prepare ammonia. The invention has the advantages of the optimization and the combination of three independent processes, namely ammonia preparation with natural gas, ammonia preparation with coal and methanol preparation with coal, system simplification, energy consumption saving, and reduction ofequipment quantity and investment.

Owner:罗庆洪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com