Combined purifying technique for ammonia preparation from natural gas, ammonia preparation from coal and methanol preparation from coal

A technology of coal-to-methanol and purification process, which is applied in the field of synthesis gas purification of natural gas to ammonia, coal to ammonia and coal to methanol, and to purification of synthesis gas from natural gas and coal to gas, which can solve the difficulty of operation and high control requirements, increasing Coal-to-ammonia gas purification process design and operation control are difficult, purification energy consumption is large, etc., to achieve the effect of reducing the number of washing stages and trays, eliminating the cooling equipment between stages, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

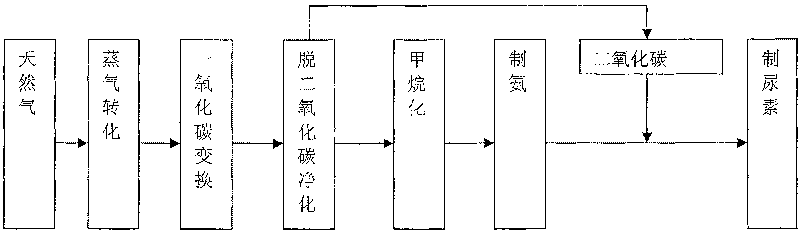

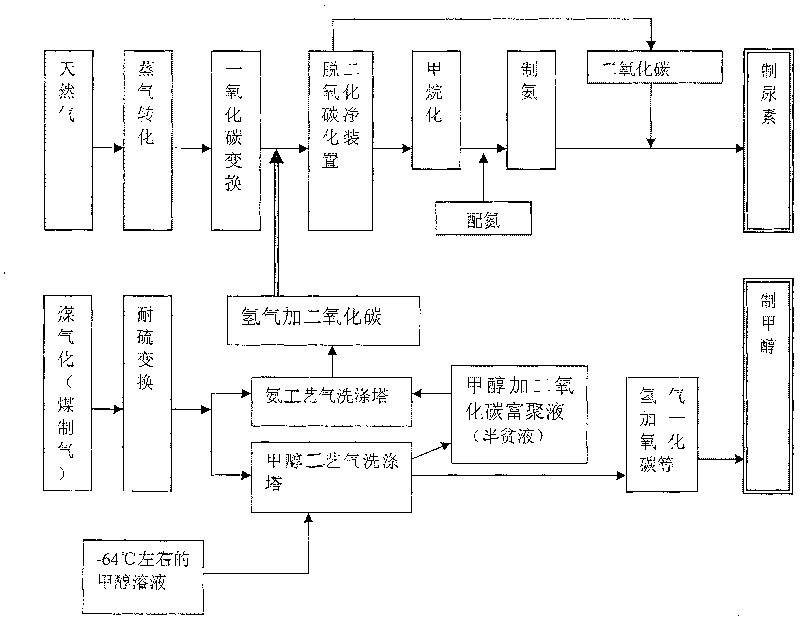

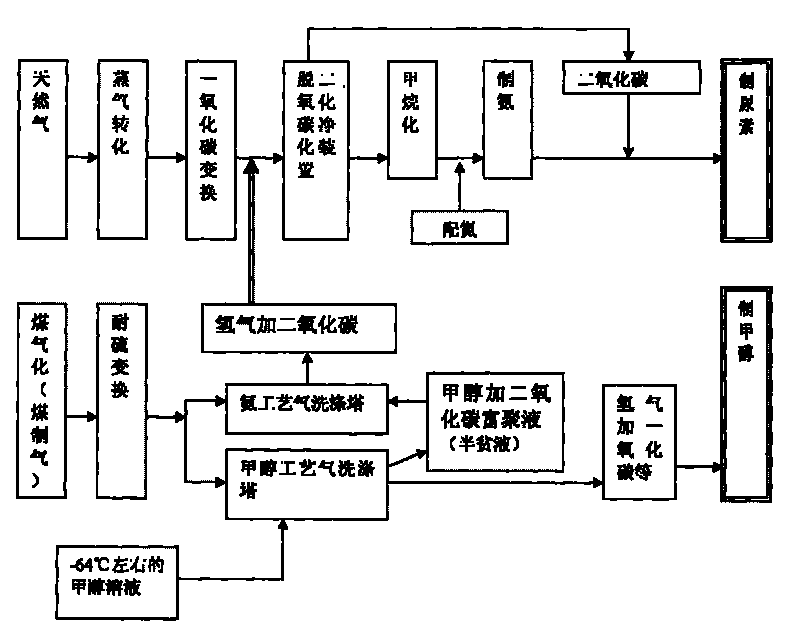

[0038] The inventor has obtained through research: the three independent processes of natural gas ammonia production process, coal ammonia production process, and coal methanol process will be combined into multi-raw material polygeneration process, and the key technology is to carry out the purification process part that the three processes all have. Comprehensive configuration to realize the optimized combined purification process, the optimized combined purification process is as follows:

[0039] The combined purification process of natural gas ammonia production and coal ammonia production and coal methanol production process of the present invention utilizes the CO removal in the purification system in the existing natural gas ammonia production process 2 purification device. In the low-temperature methanol purification system for coal-to-methanol and coal-to-ammonia process gas, the partially converted coal-to-methanol process gas from coal-to-methanol process gas is pa...

Embodiment 2

[0043] On the basis of optimizing the combined purification process in Example 1, the H discharged from the coal-to-methanol process gas scrubber 2 +CO+CO 2 The methanol synthesis gas is fed into the follow-up process and the methanol synthesis tower to prepare methanol; the coal-to-methanol process gas scrubber and the coal-to-ammonia process gas scrubber respectively discharge methanol-rich liquid, which is sulfur-containing methanol-rich liquid, containing Sulfur-methanol-rich liquid needs to be regenerated in the follow-up system to recover sulfur; after the semi-lean liquid is taken out from the coal-to-methanol process gas scrubber (CO2 has been absorbed 2 , can also absorb CO 2 methanol solution), and the semi-lean liquid is removed from the gas phase CO in the flash tank and then passed to the top of the coal-to-ammonia process gas scrubber to wash the coal-to-ammonia process gas.

[0044] When the two processes of natural gas ammonia production and coal ammonia prod...

Embodiment 3

[0046] On the basis of embodiment 2 optimization combined purification process, only two kinds of gas ratios of the following two items are preferred:

[0047] It is preferable to use the coal-to-ammonia process gas scrubber to remove the H used for ammonia synthesis 2 +CO 2 H in the mixed gas 2 The weight is enough to meet all the H consumed by the existing natural gas ammonia plant 2 50% to 80% of the weight to determine the H used for ammonia synthesis in the gas scrubber of the coal-to-ammonia process 2 +CO 2 The weight of the mixed gas; the H used for ammonia synthesis is taken out from the gas scrubber of the coal-to-ammonia process 2 +CO 2 H in the mixed gas 2 with CO 2 The weight ratio is 0.13~0.15:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com