Ionic rare earth mine ammonia nitrogen tail water denitrification treatment device and treatment method

An ionic rare earth and treatment device technology, which is applied in mining wastewater treatment, chemical instruments and methods, biological water/sewage treatment, etc. It can save energy and organic carbon sources, be easy to control and implement, and save processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

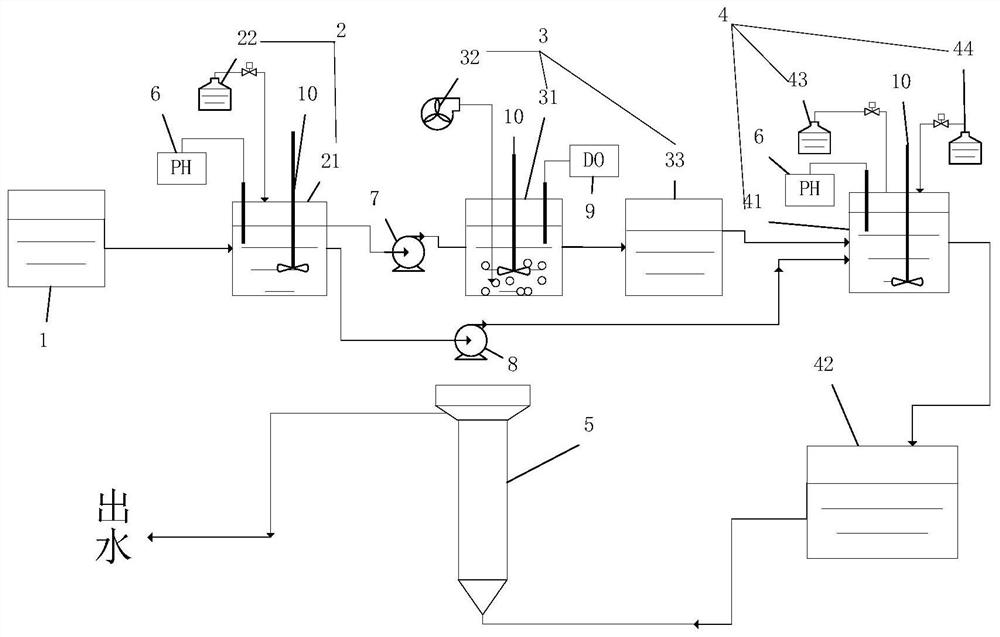

[0019] Such as figure 1 As shown, the ionic type rare earth mine ammonia nitrogen tail water treatment device includes: raw water pool 1, pretreatment component 2, nitrification reaction component 3, short-range denitrification reaction component 4, anammox reaction component 5; pretreatment component 2 and raw water The outlet of the pool 1 is connected, and the pretreatment component 2 adjusts the pH of the raw wastewater; the nitrification reaction component 3 and the pretreatment component 2 are connected through the first centrifugal pump 7, and a part of the pretreated wastewater Q1 is nitrified to remove the Ammonium nitrogen is generated into nitrate nitrogen; the short-range denitrification reaction component 4 is connected to the nitrification reaction component 3 and the short-range denitrification reaction component 4 is connected to the pretreatment component 2 through the second centrifugal pump 8, and the short-range denitrification reaction component 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com