Method and apparatus for synthesizing acetic acid by methanol low-voltage carbonylation

A technology of chemical synthesis and acetic acid, which is applied in the preparation of carboxylic acid by carbon monoxide reaction, separation/purification of carboxylic acid compound, organic chemistry, etc., can solve the problem of loss of catalytic activity, reduce mist entrainment, reduce catalyst loss, and shorten return route effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

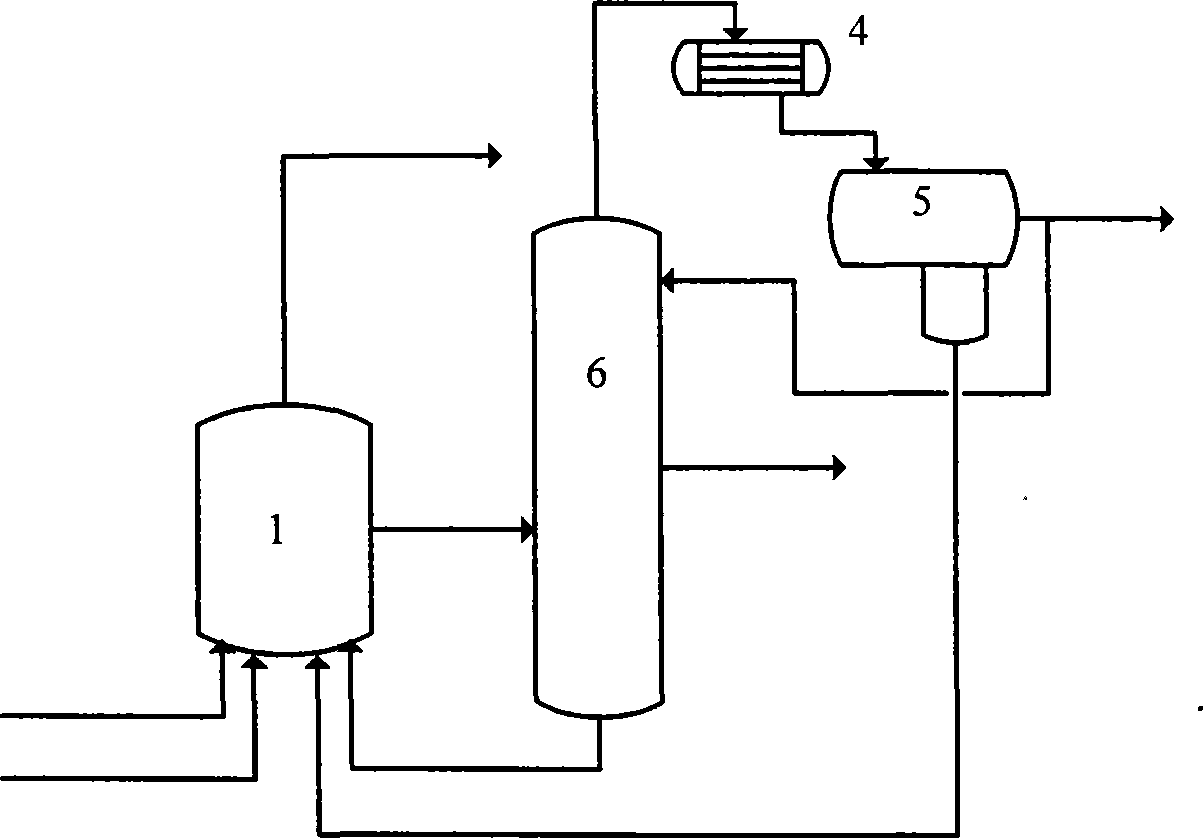

[0078] The device used in this example is figure 2 As shown, the structure of the multifunctional tower is as follows Figure 4 shown.

[0079] The stripping section A of the multifunctional tower uses trays, and the number of trays is 8. A streamline distributor is set in the flash section B.

[0080] Adopt rhodium-based catalyst, the mass percent of each component in the reaction solution is: methyl iodide 14%, water 14%, acetic acid 70%, hydrogen iodide 1%, methyl acetate 1%, catalyst content 0.03% (calculated as Rh) . The pressure of the reactor is 2.86MPa, and the reaction temperature is 185°C.

[0081] The reaction liquid is introduced into the flash section of the multifunctional tower. The gas phase obtained by flash evaporation enters the light removal section of the multifunctional tower, and adopts rectification method for separation and purification. The light removal section is controlled at a pressure of 0.15MPa. The acetic acid purity of the crude acetic a...

Embodiment 2

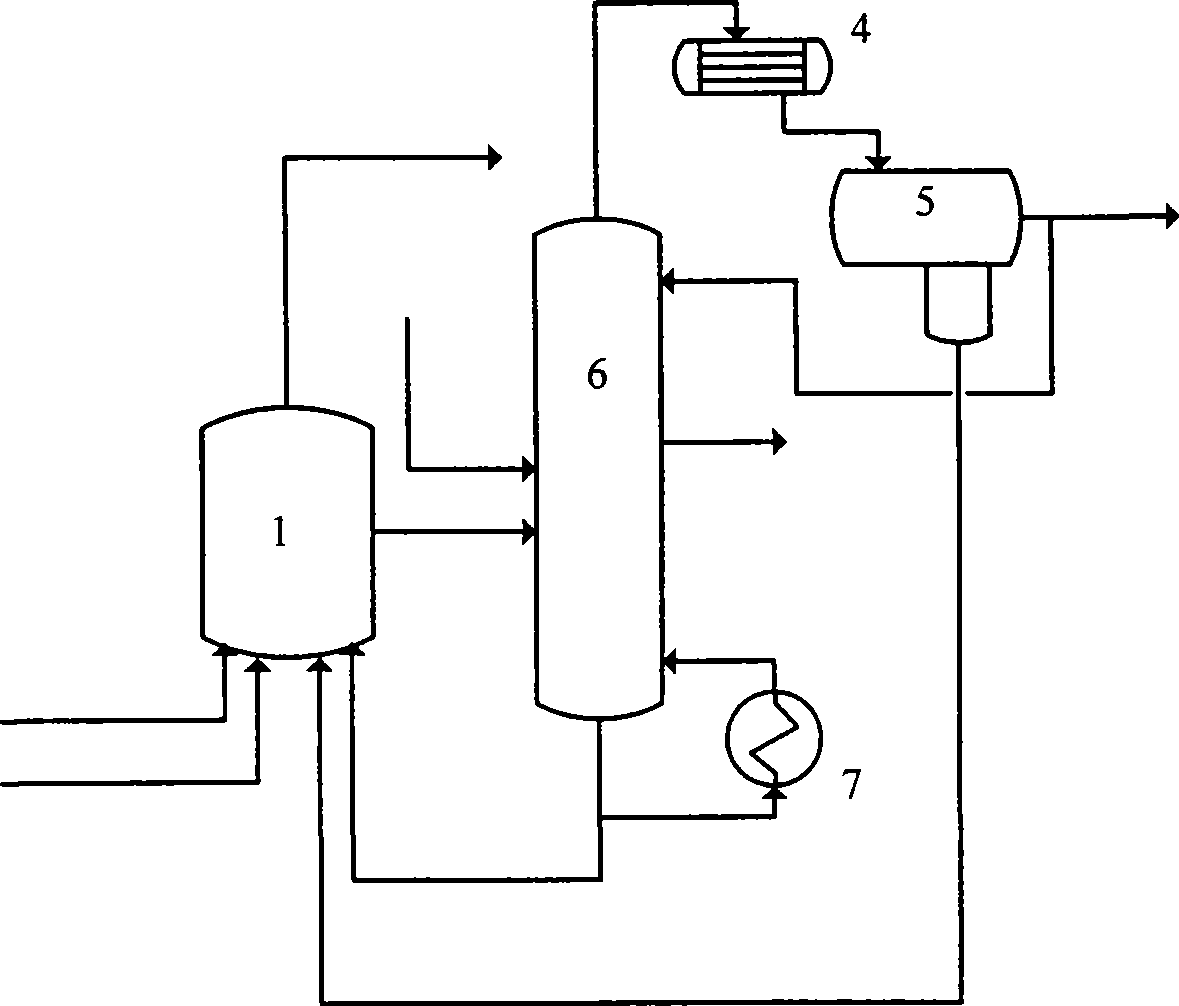

[0087] The device used in this example is image 3 As shown, the structure of the multifunctional tower is as follows Figure 5 shown.

[0088] The delightening section A of the multifunctional tower uses packing with a packing height of 5m, and the lower part 0.5m is used as the washing section C to elute the catalyst that may be entrained to the delightening section in the gas phase after flash evaporation, so as to further effectively control the loss of catalyst. A streamline distributor is set in the flash section B. The lower part of the flash section is equipped with 2 trays, which is used as the stripping section D. Add washing liquid inlet 13 and reboiler return port 14.

[0089] The rhodium-based catalyst is adopted, and the mass percentages of the components in the reaction solution are: 14% methyl iodide, 14% water, 70% acetic acid, 1% hydrogen iodide, 1% methyl acetate, and 0.03% catalyst content (calculated as Rh). The pressure of the reactor is 2.86MPa, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com