Multifunctional tower for carbonyl synthesis process of acetic acid

A carbonylation and multi-functional technology, applied in carbon monoxide reaction to prepare carboxylic acid, chemical instruments and methods, distillation and separation, etc., can solve the problems of increasing equipment investment and prolonging the process flow, so as to reduce equipment investment, simplify the process route, reduce effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

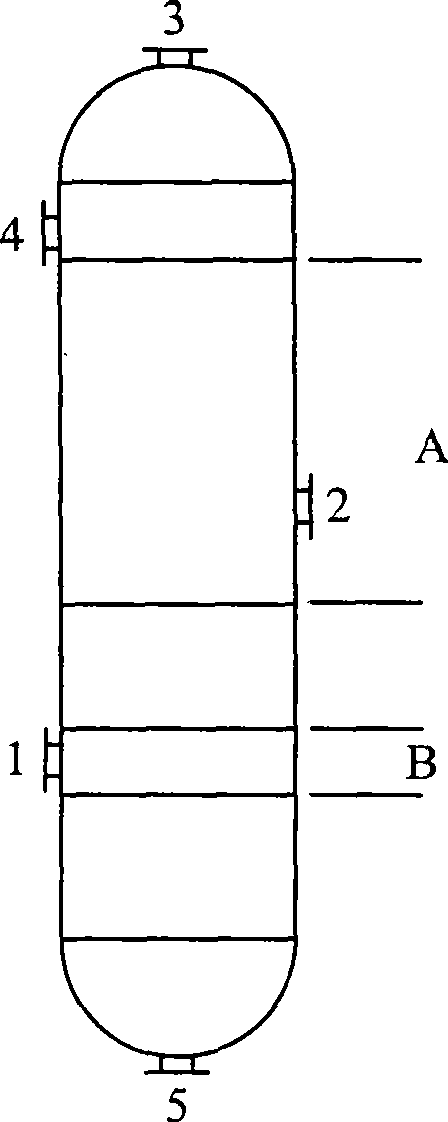

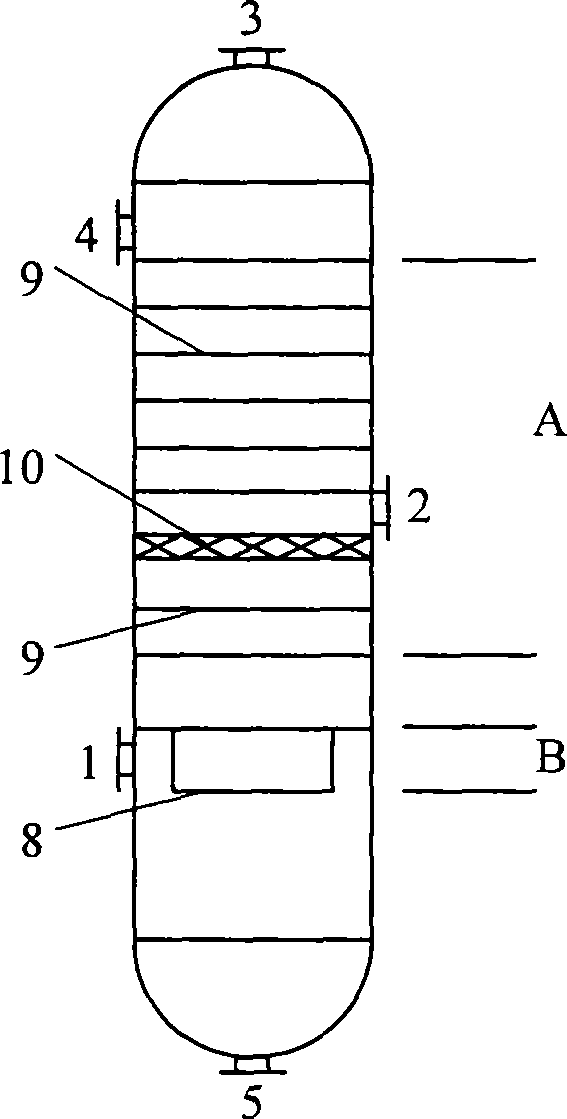

[0038] Described multi-functional column device such as figure 2 As shown, it is a vertical column, which includes light removal section A and flash evaporation section B from top to bottom. The reflux port 4, the product outlet 2 located in the light removal section and the liquid phase outlet 5 located at the bottom of the tower.

[0039] The light removal section uses trays 9, the number of trays is 8, and a demister 10 is arranged at the lower end of the product outlet. A streamline distributor 8 is set in the flash section.

[0040] When the multifunctional column is used in the oxo acetic acid unit, the catalyst-containing reaction liquid derived from the reactor enters the flashing section B of the multifunctional column from the material inlet 1, and flashes under reduced pressure It is a gas-liquid two-phase; the gas phase containing acetic acid, methyl iodide and other light components enters the light removal section A, removes the droplets containing catalysts e...

Embodiment 2

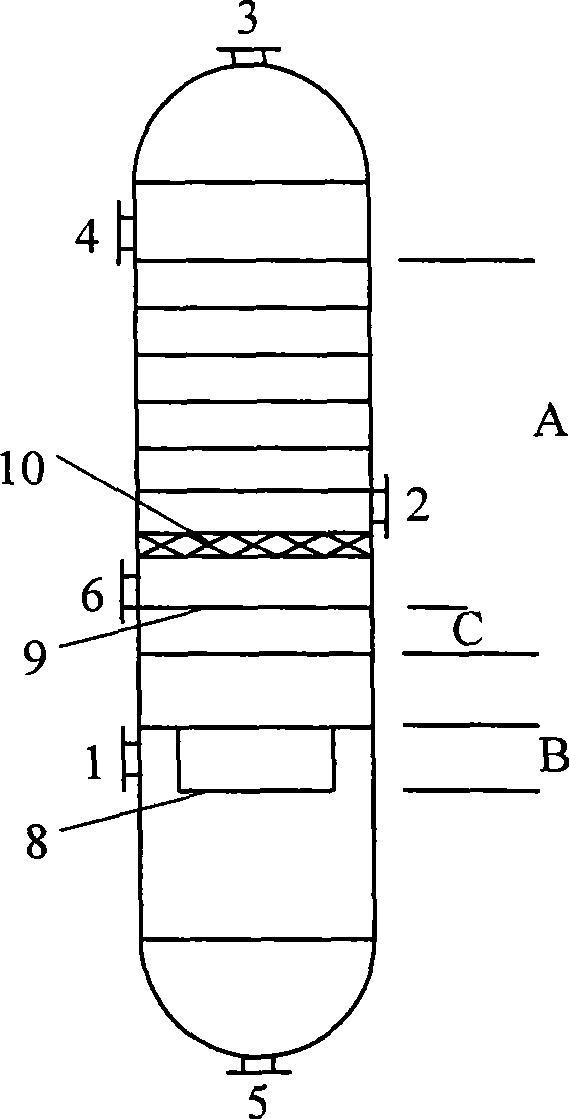

[0044] Described multi-functional column device such as image 3 As shown, the structure is similar to that of Example 1. Eight trays are set in the delightening section A, of which the lower two trays are used as the washing section C, and the washing liquid inlet 6 is set at the upper end of the washing section.

[0045] When the multi-functional column is used in the oxo acetic acid unit, the washing liquid enters the washing section from the washing liquid inlet, and the catalyst that may be entrained in the light removal section A in the gas phase after the flash is eluted, further effectively controlling the loss of the catalyst . All the other are with embodiment 1.

[0046] The washing liquid can be the liquid at the bottom of the light removal section directly entering the washing section as the washing liquid, the liquid drawn from any position in the multifunctional tower, part of the crude acetic acid obtained from the product outlet, or the liquid drawn from othe...

Embodiment 3

[0048] The multifunctional tower is as Figure 4 As shown, the stripping section A uses packing 11, the packing height is 5m, and the lower part 0.5m is used as the washing section C, and the washing liquid inlet 6 is set at the upper end of the washing section. A streamline distributor 8 is set at the flash section B. The lower part of the flash section is equipped with 2 trays, which is used as the stripping section D. Set the material return port 7.

[0049] When the multifunctional column is used in the oxo-synthetic acetic acid unit, the bottom of the multifunctional column obtains the catalyst-containing reaction raffinate part into the reboiler, and the gas-liquid mixture obtained by heating, the gas-liquid mixture is obtained from the reboiler After the top comes out, it enters the lower end of the stripping section of the multifunctional tower from the stream return port 7 to provide stripping steam for the stripping section. Its using method is the same as embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com