Data-driven modeling furnace temperature control method applied to rotary kiln for hazardous waste incineration

A hazardous waste, data-driven technology, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve problems such as economic loss, unplanned downtime, low efficiency, etc., to improve economic benefits, reduce control difficulty, The effect of reducing the degree of dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

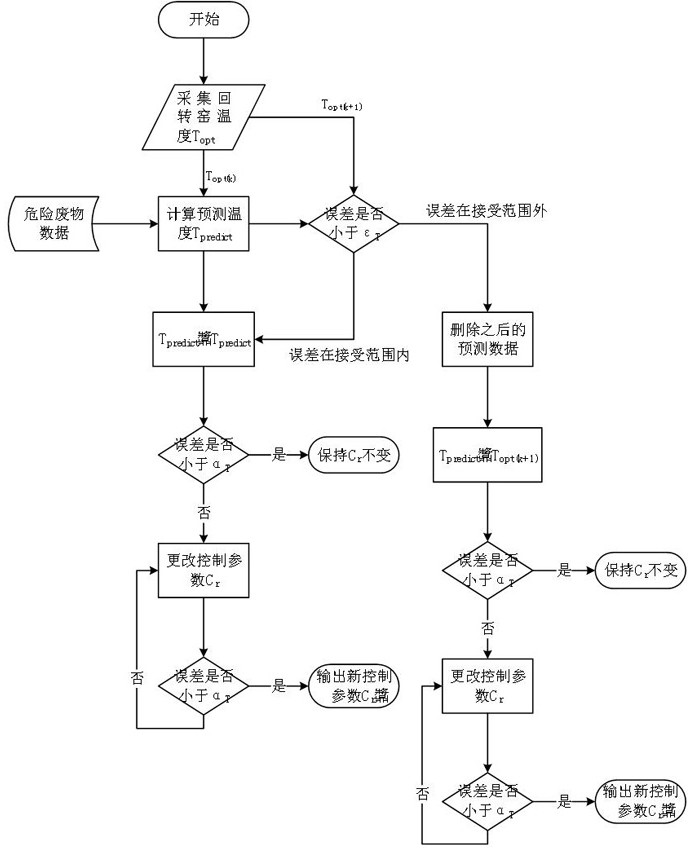

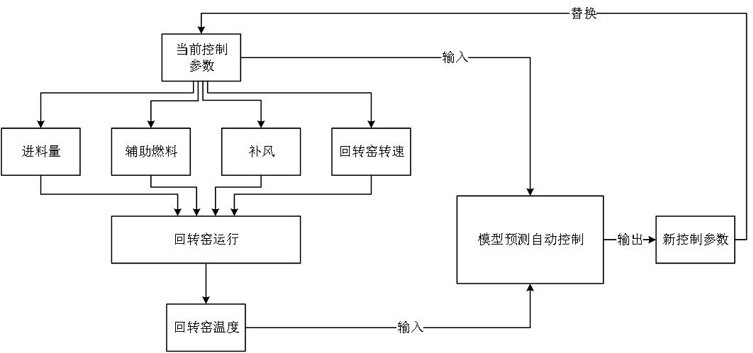

[0054] In this embodiment, the historical operation data of the rotary kiln is used to fit the prediction model, and the nonlinear relationship between the control parameters of the rotary kiln and the temperature of the rotary kiln is established through the autoregressive sliding average modeling method, and the model structure parameters and model estimation parameters are obtained. Input the obtained temperature prediction model into the rotary kiln model prediction control unit.

[0055] Sampling and analyzing the hazardous wastes that are going to enter the rotary kiln for incineration according to the categories, and obtain the physical property data, industrial analysis data and elemental analysis data of the hazardous wastes. Organize and package the obtained data into a hazardous waste database, so that it can be called in the process of model prediction calculation.

[0056] The rotary kiln is turned on, and auxiliary fuel is injected so that the temperature in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com