Chewy and elastic fresh-keeping rice noodle and preparation method thereof

An elastic, rice noodle technology, applied in the fields of food preservation, food science, food ultrasonic treatment, etc., can solve the problems of large cooking loss, reduced rice noodle quality, and high breakage rate, and achieves low difficulty in operation control, low cooking loss, and equipment investment. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

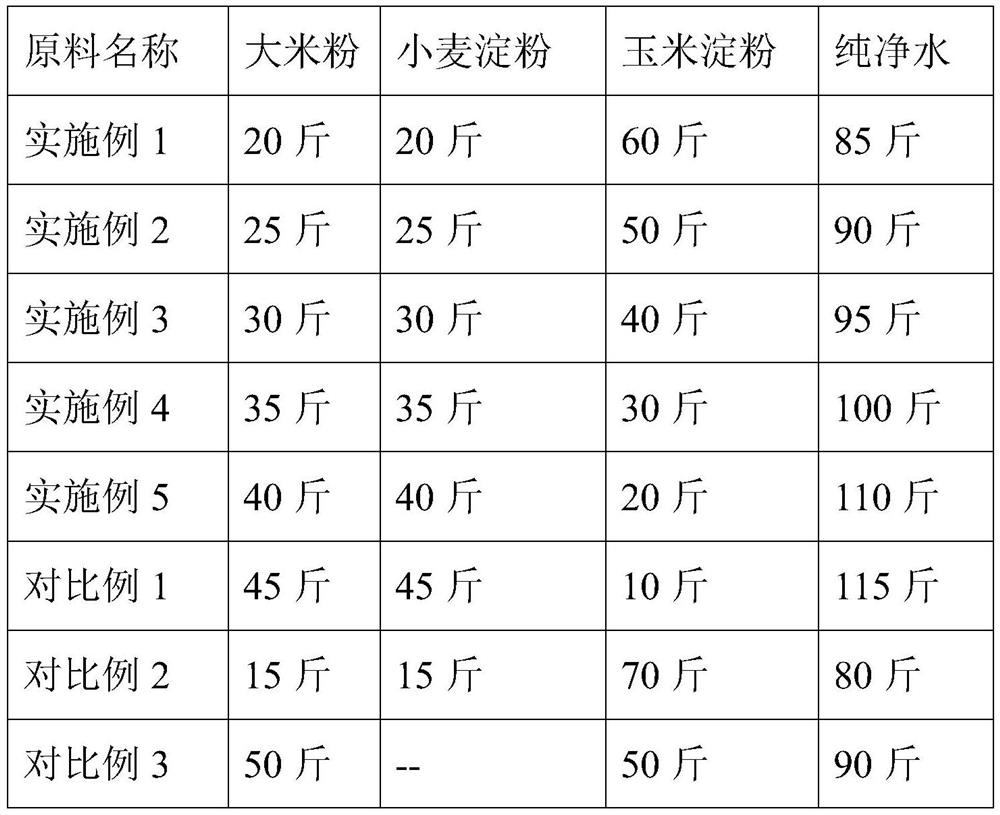

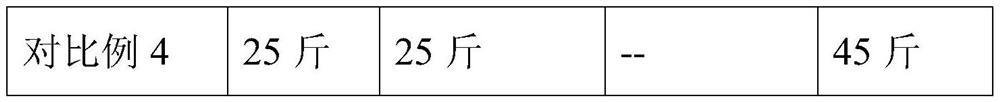

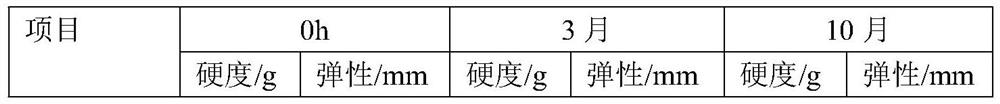

Embodiment 1-5 comparative example 1-4

[0036] In the present invention, for the screening of rice flour raw materials, factors such as texture, physical and chemical property differences, amylose and amylopectin content differences, and protein differences of different sources of starch are considered to match, and in "Rice Flour Mixing Flour and Starch Rheology" Research on the Effects of Characteristics on the Quality of Rice Flour also emphasizes that starch has an important influence on the quality of rice flour. The characteristics of starch are closely related to the quality of rice flour. The starch content, especially the proportion of amylose, will directly affect the quality of rice flour. Quality; while rice starch is not ideal in terms of elasticity and breaking rate, so potato starch is usually added to improve the elasticity, tendon strength, and bite strength of the powder, prolong the shelf life, and shorten the rehydration time. Adding cassava starch can improve the luster and toughness of rice flou...

Embodiment 6

[0047] The difference with Example 1 is that the processing method of the rice flour is: take the unaged rice and mechanically grind it into a powder with a sieve residue of 6-8% through a 50-mesh sieve, and then according to the mass ratio of water: powder =2:1 Soak the powder in water and perform intermittent ultrasonic treatment during the soaking process, take the wet powder and process it with ultra-high pressure, and then grind it until the sieve residue of 100 mesh sieve is ≤5%.

[0048] The working conditions of the intermittent ultrasound are: power 100W, frequency of ultrasonic treatment is 20kHz, frequency of ultrasonic treatment is 2 times, intermittent time is 30s, and time of each ultrasonic treatment is 90s;

[0049] The working conditions of the ultra-high pressure treatment are: normal temperature, a pressure of 120Mpa is applied, and the pressure is maintained for 10 minutes.

Embodiment 7

[0051] The difference with Example 1 is that the processing method of the rice flour is: take the unaged rice and mechanically grind it into a powder with a sieve residue of 6-8% through a 50-mesh sieve, and then according to the mass ratio of water: powder =2.6:1 Soak the powder in water and perform intermittent ultrasonic treatment during the soaking process, take the wet powder and process it with ultra-high pressure, and then grind it to a 100-mesh sieve with a sieve balance of ≤ 5%.

[0052] The working conditions of the intermittent ultrasound are: power 130W, frequency of ultrasonic treatment is 40kHz, frequency of ultrasonic treatment is 5 times, intermittent time is 60s, and time of each ultrasonic treatment is 150s;

[0053] The working conditions of the ultra-high pressure treatment are: normal temperature, a pressure of 270Mpa is applied, and the pressure is maintained for 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com