Reactive distillation device and method for separating and purifying methylal

A technology of methylal and formaldehyde, applied in chemical instruments and methods, fractionation, preparation of organic compounds, etc., can solve problems such as raw material can not be contained, influence of rectification, increase of side reactions, etc., to overcome difficulty in control and improve reaction rate , the effect of improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

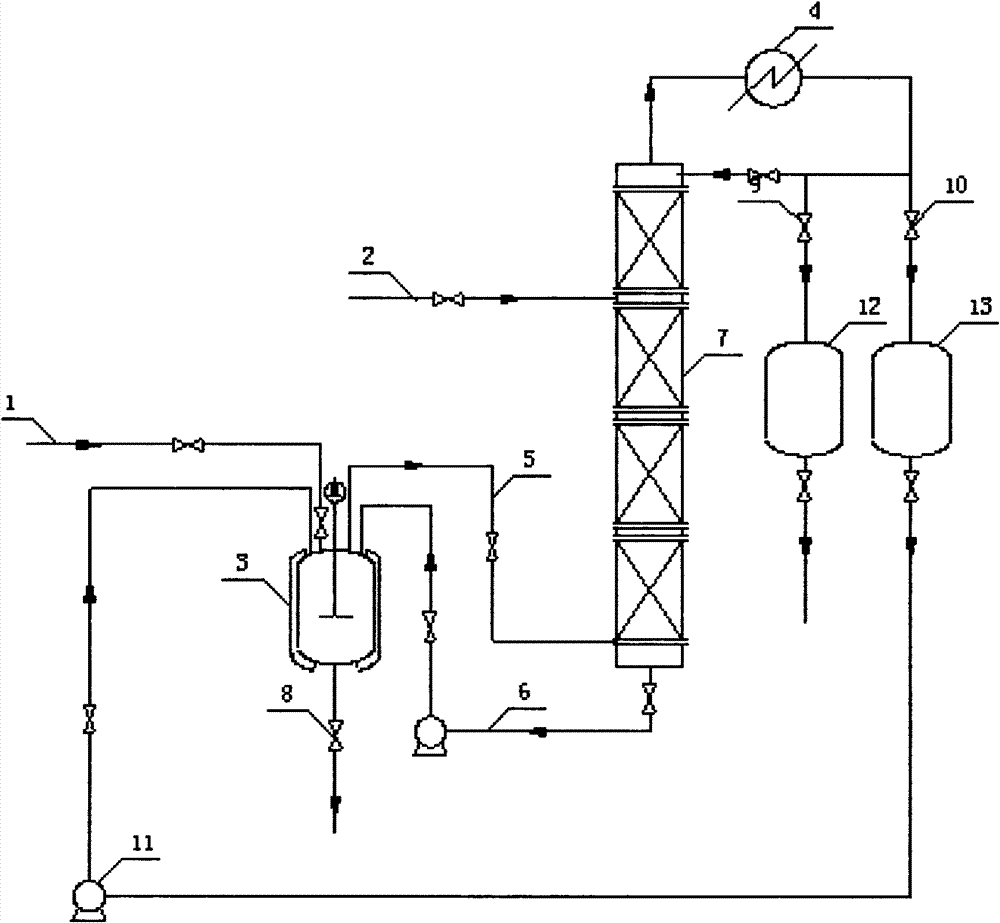

[0025] The present invention is described in detail in conjunction with the accompanying drawings.

[0026] As shown in the figure, 1-methanol feed; 2-formaldehyde feed; 3-reactor; 4-condenser; 5-methylal delivery pipeline; 6-bottom reflux liquid; The valve 8, the second valve 9, and the third valve 10 are pipeline control valves; 11-reflux pump. The θ (3×3) stainless steel filler is filled in the rectification column, and the number of theoretical plates is about 30 to 40.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com