Sludge treatment process

A sludge disposal and process technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of increasing process difficulty and load, no sludge pollution, secondary pollution and other problems, to achieve the effect of simplifying the sludge disposal process, saving energy consumption and scale, reducing energy consumption and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

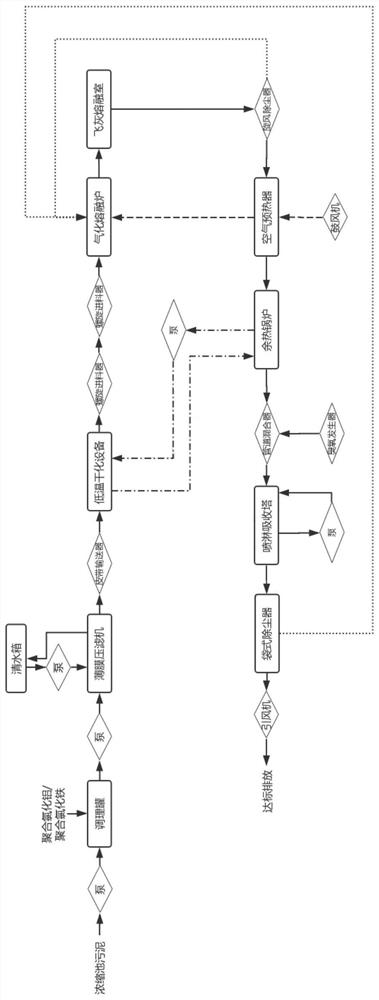

[0027] The present invention is introduced below by accompanying drawing.

[0028] figure 1 is a schematic flow chart of the sludge disposal process according to the present invention. Such as figure 1 As shown, firstly, the sludge in the sludge thickening tank is pumped to the sludge conditioning tank to stir and condition the sludge. According to the present invention, the sludge disposal process can directly treat the sludge in the sludge thickening tank. The sludge in the sludge thickening tank can be lifted by a submersible sewage pump or a self-priming centrifugal pump, and then pumped to the sludge conditioning tank.

[0029] After the sludge is pumped to the sludge conditioning tank, an inorganic conditioner is added to the sludge conditioning tank. The inorganic conditioner can be polyaluminum chloride or polyferric chloride. The addition amount of polyaluminum chloride or polyferric chloride is 5-20wt% of the absolute dry sludge. Polyaluminum chloride or polyfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com