Clamping device based on shape memory alloy wires and control method of clamping device

A memory alloy wire and gripper technology, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of poor expandability of flexible grippers, and achieve the effect of low difficulty in operation control and strong expandability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

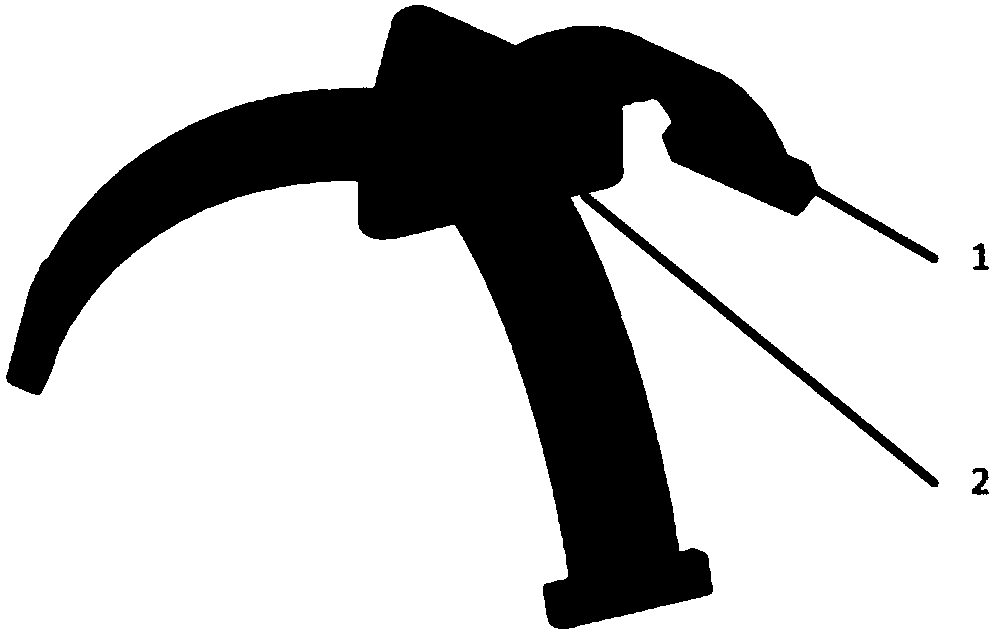

[0018] A clamper based on shape memory alloy wire, comprising: a connecting piece 2 and a clamping arm 1 .

[0019] The holding arm 1 is composed of a PCB board and a shape memory alloy wire. There are two PCB boards in total, and there are multiple sections of shape memory alloy wires arranged in parallel in the same plane between the two PCB boards. The entire PCB board and the shape memory alloy wire are wrapped by a soft material with curing function. There are multiple holding arms 1 and one end is all connected to the connecting piece 2 . The shape-memory alloy wires between the two PCB boards have multiple layers, and the multi-layer shape-memory alloy wires are arranged in parallel. The shape memory alloy wire between the two PCB boards is formed by winding a shape memory alloy wire back and forth between the two PCB boards. The soft material with curing function is thermosetting glue or thermosetting resin. A plurality of holding arms 1 are arranged radially and sy...

Embodiment 2

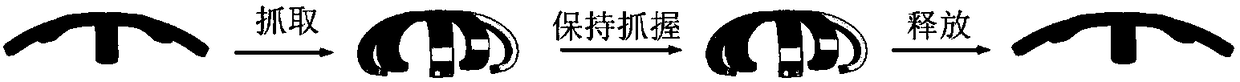

[0021] The specific steps of a control method based on a shape memory alloy wire holder are as follows:

[0022] The shape-memory alloy wires of multiple clamping arms 1 are all connected to the single-chip microcomputer, and the single-chip microcomputer performs independent heating control on each clamping arm 1 by adjusting the waveform of the voltage according to the timing parameters corresponding to different motion modes, so that the clamping arm 1 completes gripping or Slack movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com