Backpressure steam turbine regenerative system with small steam turbine and design method of thermodynamic equilibrium

A heat recovery system and small steam turbine technology, applied in mechanical equipment, separation methods, steam engine devices, etc., can solve problems such as flexible adjustment of unfavorable heating load and safe operation, complicated operation adjustment, cold end loss, etc., to achieve oxygen removal The effect is good, the number is reduced, and the system efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

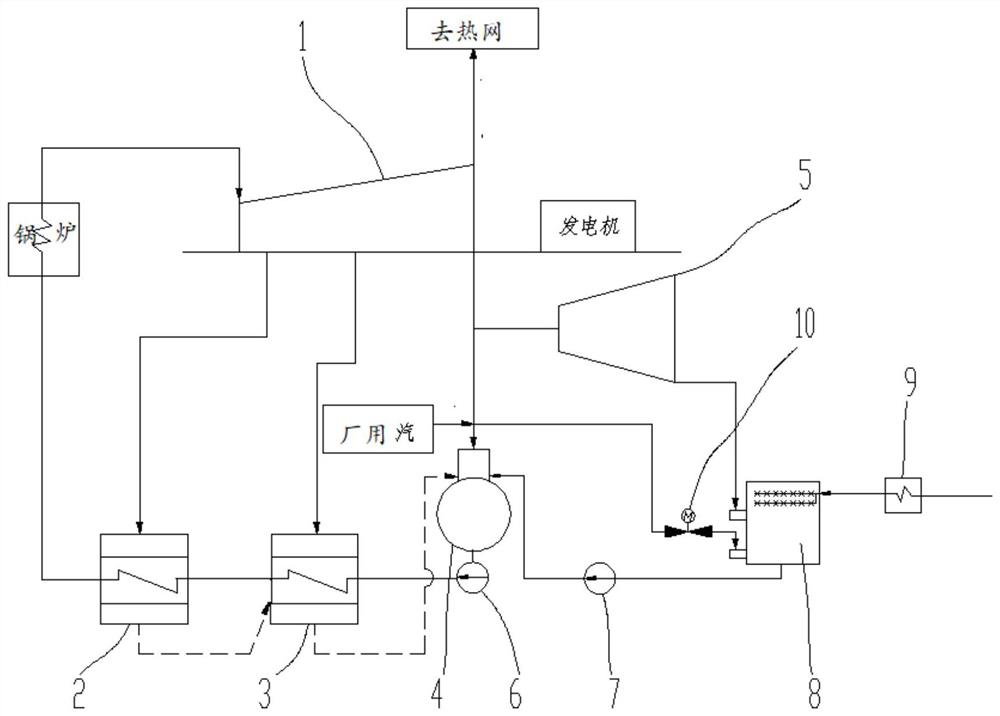

[0035] Such as figure 1 As shown, the above-mentioned back-pressure steam turbine heat recovery system at least includes a back-pressure steam turbine 1, auxiliary devices, water supply power devices, small steam turbine 5, and a condenser. Wherein, the auxiliary device is connected with the back pressure steam turbine 1 for heating and deoxygenating the replenishment water and return water of the regenerating system, and the water supply power device provides power for the system replenishment and return water, so that it can be used in the regenerating system. Circulating flow in the system; and the small steam turbine 5 is connected with the back pressure steam turbine 1, which can drive the water supply power device, and the condenser 8 is connected with the small steam turbine 5; it should be noted that the condenser 8 is used as In addition to the steam exhaust condensing equipment of the small steam turbine 5, it is also used as the primary deoxygenation and heating equ...

Embodiment 2

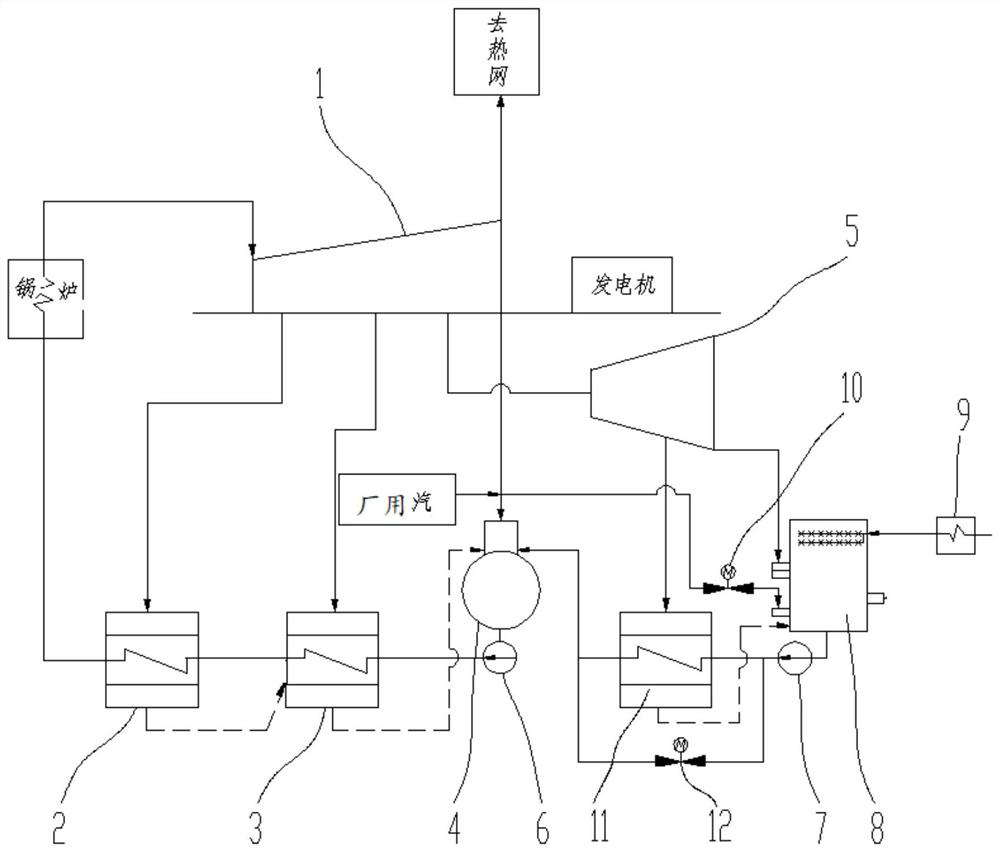

[0058] When the power and flow rate of the small steam turbine 5 do not meet the requirements of the system, and the design pressure of the condenser 8 is unreasonable, resulting in an increase in equipment cost, difficulty in operation, or a decrease in system efficiency, the scheme of this embodiment can be used for optimization. This embodiment is a further improvement of Embodiment 1. The main improvement is that the back-pressure steam turbine 1 heat recovery system also includes low-pressure heaters I 11 respectively connected to the water supply power device and the auxiliary device. The low-pressure heater I11 is also connected to the small steam turbine 5 through a heat recovery pipeline; the low-pressure heater I11 is also connected with a bypass regulating valve 12, and the low-pressure heating is adjusted by bypassing part of the water side flow of the low-pressure heater I11 The amount of reheated steam used in device I11.

[0059] Such as figure 2 As shown, for...

Embodiment 3

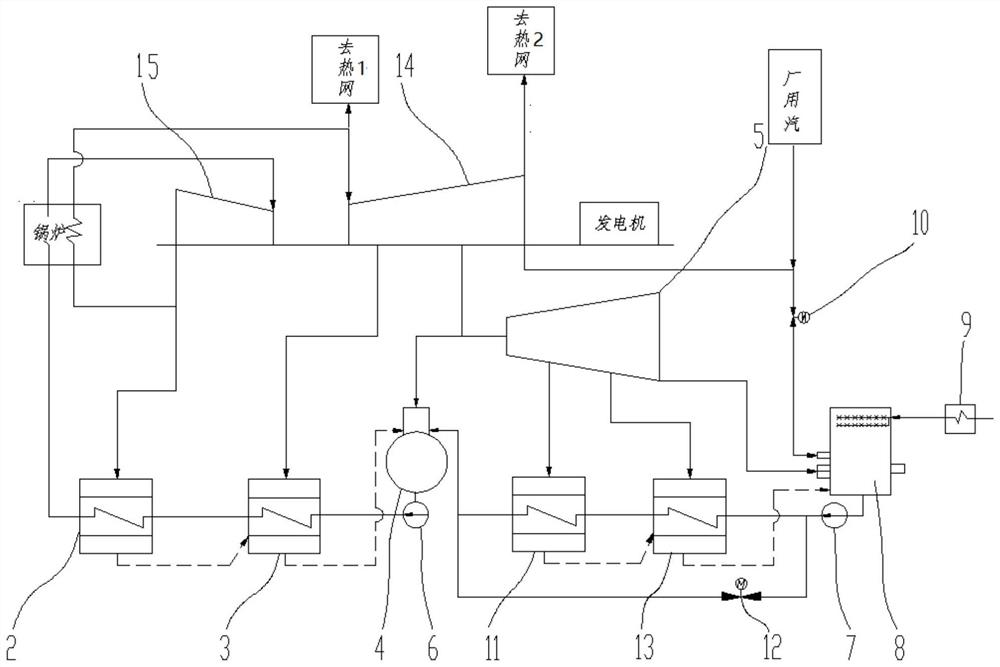

[0064] Embodiment three is also a further improvement of embodiment one, as image 3 As shown, the main improvement is that the backpressure steam turbine 1 is a reheating backpressure steam turbine 1 . This kind of reheating steam turbine is to send the steam that has done work in the high pressure cylinder of the steam turbine back to the reheater of the boiler to be heated to a temperature close to that of the new steam, and then return to the middle and low pressure cylinder of the steam turbine to continue to work. The intermediate reheating of the steam not only reduces the exhaust steam humidity of the steam turbine, but also improves the working conditions of the blades of the last stages of the steam turbine and improves the relative internal efficiency of the steam turbine. For the reheating back pressure steam turbine, different from the non-reheating back pressure steam turbine, the matching of the steam temperature and pressure after the reheater has changed, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com