A kind of production method of 1,4-naphthoquinone, adopted catalyst and its application

A production method and catalyst technology, which is applied in the field of fine chemical synthesis, can solve the problems of low naphthalene conversion rate, high yield, and low cost, and achieve the effects of simple post-treatment process, low difficulty in operation control, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

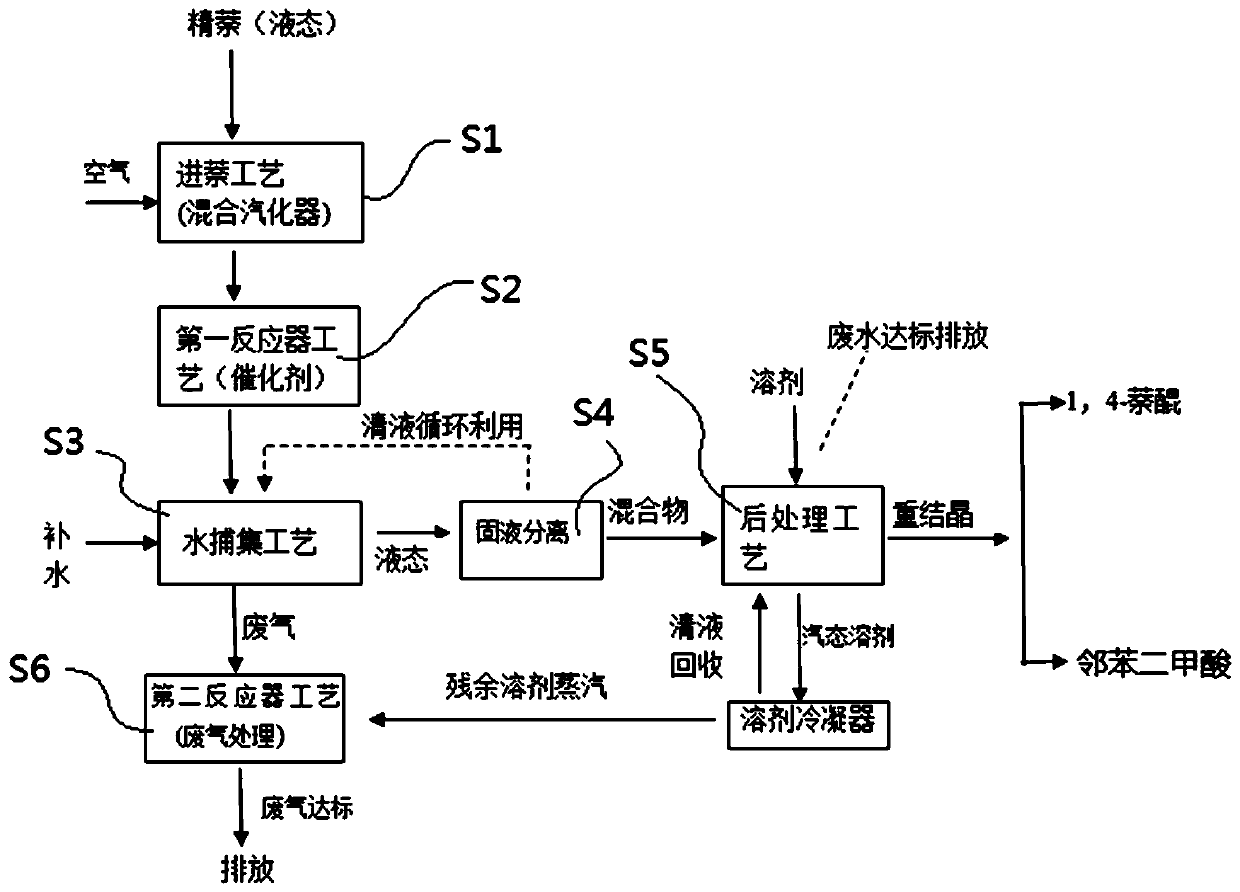

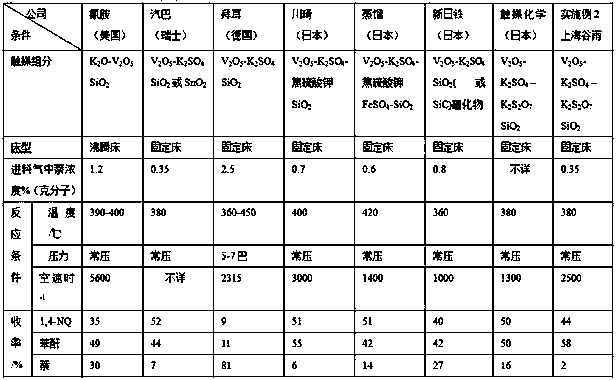

Method used

Image

Examples

preparation example Construction

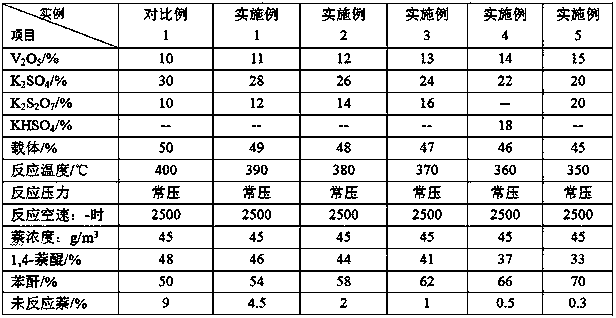

[0039] The preparation method of the first catalyst is to adopt 11~15% vanadium pentoxide, 20-30% potassium sulfate, 10~20% auxiliary agent (potassium pyrosulfate or potassium bisulfate or a mixture of the two) and 45% ~50% carrier (SiO 2 、Al 2 o 3 , SiO 2 -Al 2 o 3 、Al 2 o 3 -TiO 2 Any one of them or any mixture of two or more) mixed, dried at 60~100°C in different periods (at least 2 times of drying), kept at 100~150°C for 2~4 hours to ensure that the dehydration is complete, and prepared into a diameter of ¢4~ 8mm, 4~8mm high ring-shaped catalyst, activated by calcination at 150~500°C and a small amount of air (providing oxygen to increase the valence state of vanadium) in different periods, and at 450~500°C for 4~6 hours to improve the thermal stability of the catalyst The first catalyst of the present invention is obtained by natural cooling.

[0040] In the first catalyst, the addition of potassium sulfate may lead to an increase or decrease in the yield of naph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com