High-temperature baking resistant phenolic molding compound and preparation method thereof

A technology of phenolic molding compound and high temperature resistance, applied in the field of phenolic molding compound and its preparation, can solve the problems of reducing the thermal stability of phenolic resin and affecting the baking resistance of bakelite products, and achieve the effect of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific drawings.

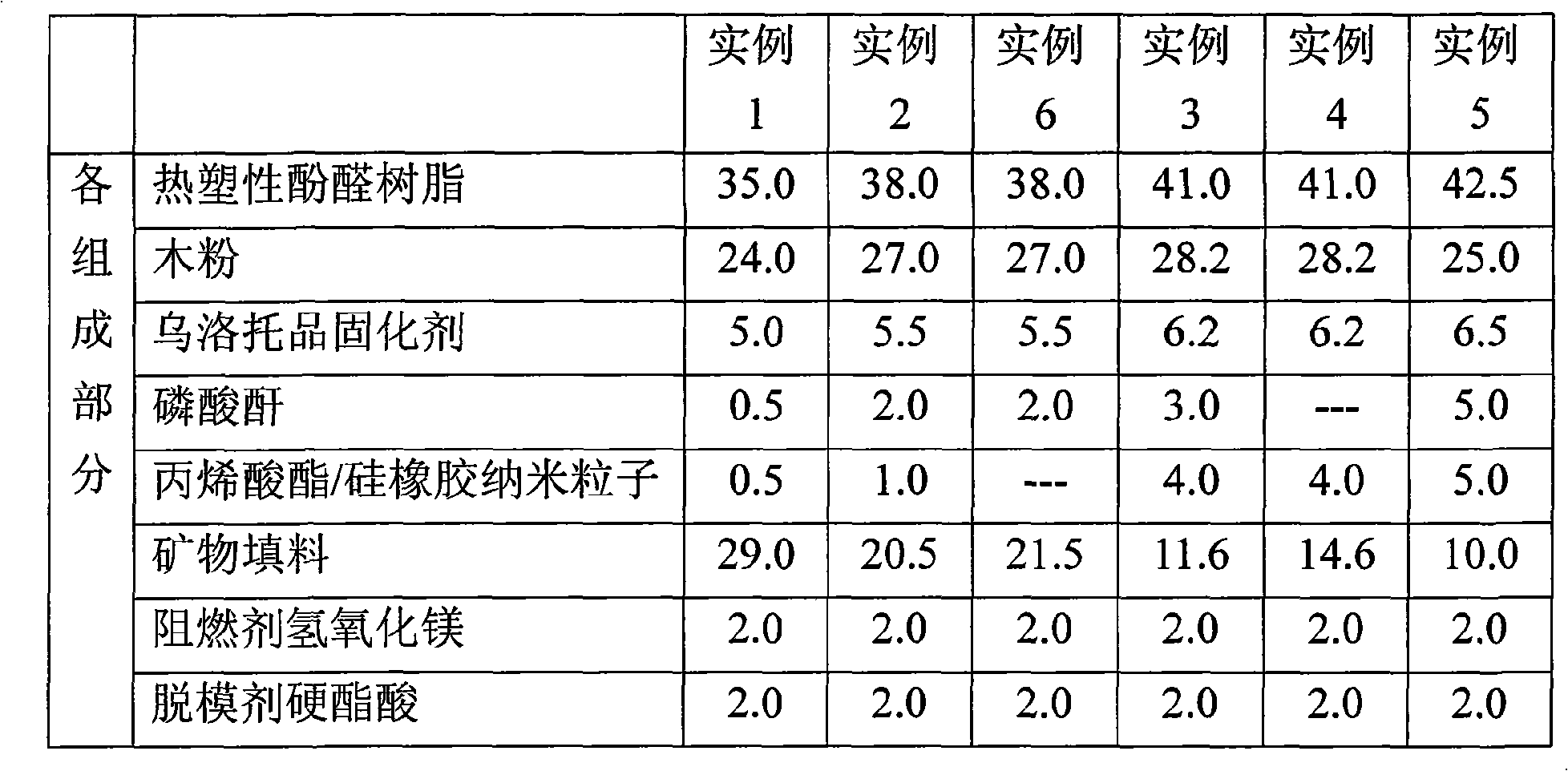

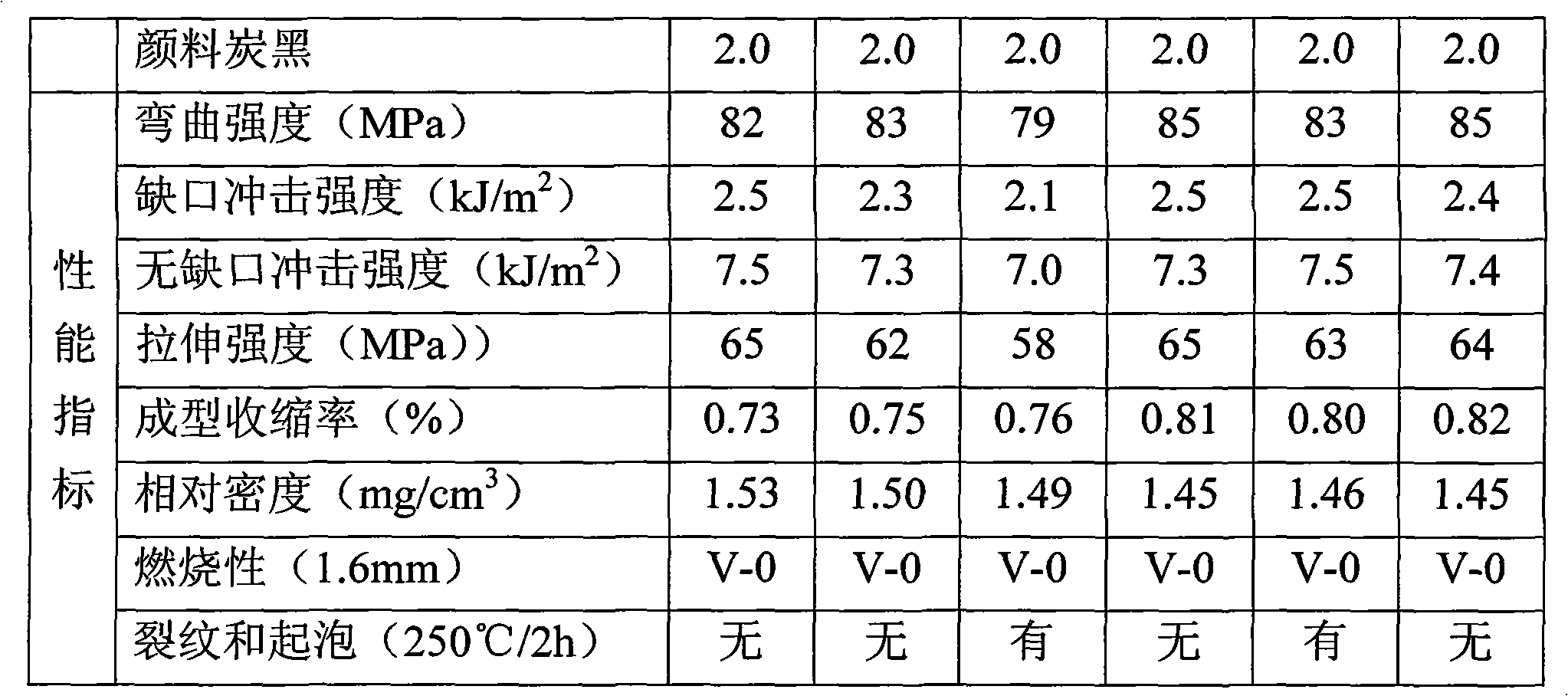

[0025] The present invention discloses a high-temperature baking resistant phenolic molding compound, which contains additives and further includes the following components: (1) phenolic resin with a content of 30 to 48%; (2) wood flour with a content of 10 to 40%; 3) Mineral filler, the content is 10-30%; (4) Urotropine curing agent, the content is 4.0-9.0%; (5) Phosphoric anhydride catalyst, the content is 0.5-5.0%; (6) Acrylate nanoparticles Or silicone rubber nanoparticles, the content is 0.5-5.0%. The additives include pigments, lubricants, flame retardants, mold release agents, etc., which are well-known technologies in the field of the present invention.

[0026] The present invention uses phenolic resin as a binder. The phenolic resin used is an aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com