Mesoporous bioactive glass material with apatite nanocrystallines and method for producing mesoporous bioactive glass material with apatite nanocrystallines

A bioactive glass and apatite technology, applied in the field of biomaterials, can solve the problems of uncontrollable and time-consuming apatite nanocrystals, and achieve the effects of simple operation, simple raw materials, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Using sucrose as raw material to prepare carbon spheres to synthesize mesoporous bioactive glass M60S-1C containing hydroxyapatite nanocrystals

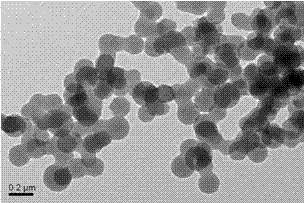

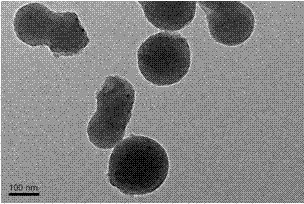

[0043] Dissolve 60 grams of sucrose in 200 ml of ultra-pure water to form a clear solution, transfer it to a 250 ml hydrothermal kettle, seal it, heat it at 140°C for 36 hours, filter it with suction, wash it with deionized water and ethanol, and dry it That is, carbon sphere powder. The resulting carbon spheres are 200 nanometers to 1 micron through electron microscope inspection, see figure 1 .

[0044] Dissolve 2 g of cetyltrimethylammonium bromide (CTAB) in 100 ml of deionized water, adjust the pH value of the solution below 2 with nitric acid, and stir until clear at 30°C. According to the molar ratio of silicon dioxide: calcium oxide: phosphorus pentoxide is 60:36:4, add 5.62 grams of ethyl orthosilicate, 1.64 grams of triethyl phosphate, 1.80 grams of calcium chloride, according to calcium chloride: carbon ...

Embodiment 2

[0045] Example 2: Using sucrose as raw material to prepare carbon spheres to synthesize mesoporous bioactive glass M80S-2C containing hydroxyapatite nanocrystals

[0046] Prepare carbon sphere powder and structure directing agent solution according to the steps and raw material ratio of Example 1. According to silicon dioxide: calcium oxide: the mol ratio of phosphorus pentoxide is 80:15:5, add 7.49 gram tetraethyl orthosilicate, 0.82 gram triethyl phosphate, 0.56 gram calcium chloride, 1.11 gram carbon sphere powder ( Calcium chloride: carbon sphere mass ratio is 1:2), stirred at 50°C for 72 hours, dried at 90°C and calcined at 650°C for 6 hours to obtain mesoporous bioactive glass M80S containing hydroxyapatite nanocrystals -2C.

Embodiment 3

[0047] Example 3: Using sucrose as raw material to prepare carbon spheres to synthesize mesoporous bioactive glass M80S-10C containing hydroxyapatite nanocrystals

[0048] Prepare carbon sphere powder and precursor solution according to the steps and raw material ratio of Example 2. Add 7.49 grams of ethyl orthosilicate, 0.82 grams of triethyl phosphate, 1.60 grams of calcium nitrate, add 15.92 grams of carbon sphere powder according to the mass ratio of calcium nitrate:carbon spheres of 1:10, stir at 80°C for 96 hours, and dry at 110°C After that, it was calcined at 700° C. for 5 hours to obtain the mesoporous bioactive glass M80S-10C containing hydroxyapatite nanocrystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com