Controlled release mixed and compound fertilizer and preparation method thereof

A technology of slow-release compound fertilizer and compound fertilizer, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of high price of coating auxiliary agent, high production cost of slow-release fertilizer, low utilization efficiency of by-products, etc. Achieve the effect of improving sustainability, benefiting growth and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

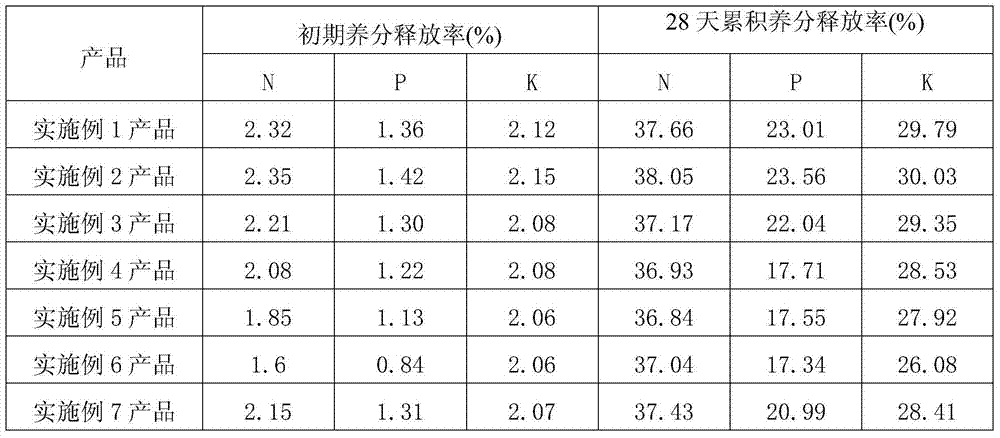

Examples

preparation example Construction

[0026] The preparation method of the slow-release compound fertilizer of the present invention comprises the following steps: weighing 0.1-30% of the by-products of the wet-process phosphoric acid industry and 0.1-20% of the coating auxiliary, which account for 0.1-30% of the total weight of the slow-release compound fertilizer, and mixing them evenly Then, 2-12% water is added to coat the compound fertilizer granules, and after drying, the finished product of slow-release compound fertilizer granules is obtained.

[0027] Further, the compound fertilizer granules can be prepared by the following method: nitrogen, phosphate, potassium fertilizers with a weight ratio of nitrogen, phosphorus and potassium to 4-25:4-25:4-25 and The granulation adjuvant, which accounts for 0.1-29% of the total weight of the compound fertilizer, is mixed evenly, among which nitrogen, phosphorus and potassium are three nutrients (N+P 2 O 5 +K 2 The total mass fraction of O) is 25-60%, adding 0.5-1...

Embodiment 1

[0032] (1) Nucleation

[0033] Put ammonium sulfate, heavy calcium and potassium sulfate in the 4:15:10 ratio of nitrogen, phosphorus and potassium into the granulator, and add the granulation auxiliary chalk soil that accounts for 22% of the total compound fertilizer. , mix evenly, add 10% water, granulate, dry and sieve to obtain compound fertilizer granules with a particle size of 3-5mm for use.

[0034] (2) Shell making

[0035] Put the above-mentioned standby compound fertilizer granules into the coating machine, add fertilizer grade calcium hydrogen phosphate with a water content of 48%, and 5% molasses, which account for 15% of the total portion of the slow-release fertilizer, and add a coating material that accounts for the total amount of the coating material and moisture. 2% water. The compound fertilizer granules are coated and then dried to obtain the finished product of slow-release compound fertilizer granules.

Embodiment 2

[0037] (1) Nucleation

[0038] Put ammonium chloride, monoammonium phosphate and potassium sulfate in the 15:4:10 nutrient ratio of nitrogen, phosphorus and potassium into the granulator, and add granulation auxiliary which accounts for 20% of the total compound fertilizer. The chalk soil was added with 12% water, granulated, dried and sieved to obtain compound fertilizer granules with a particle size of 3-5 mm for later use.

[0039] (2) Shell making

[0040] Put the above-mentioned standby compound fertilizer granules into the coating machine, add ammonium phosphate residue accounting for 13% of the total part of slow-release fertilizer, 7% coal slime, and add water accounting for 9% of the total part of coating material and moisture. . The compound fertilizer granules are coated and then dried to obtain the finished product of slow-release compound fertilizer granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com