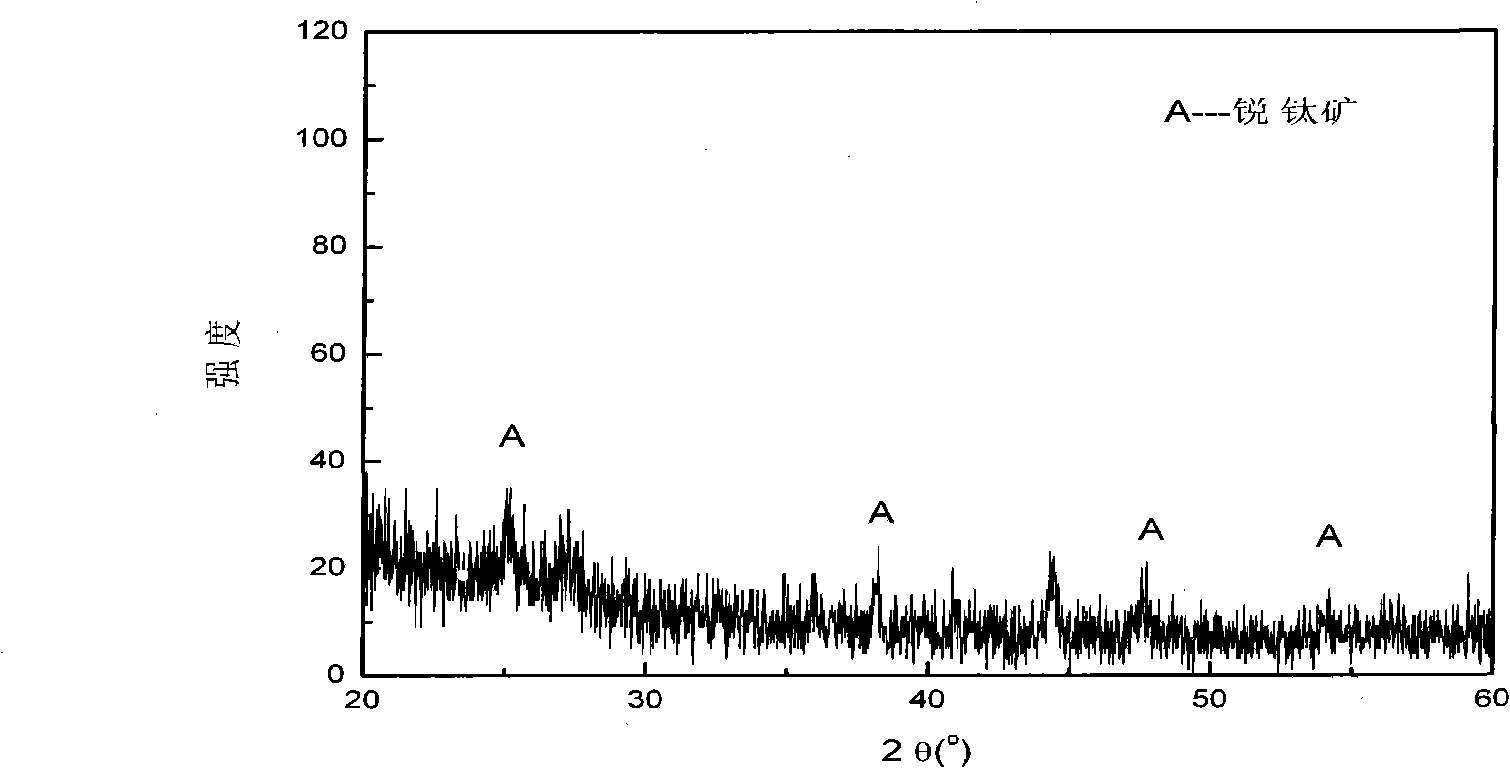

Method for preparing titanium dioxide crystalline state film at low-temperature

A technology of titanium dioxide and nano-titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, coating, etc., can solve the problems of long cycle and achieve the effect of simple preparation method and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

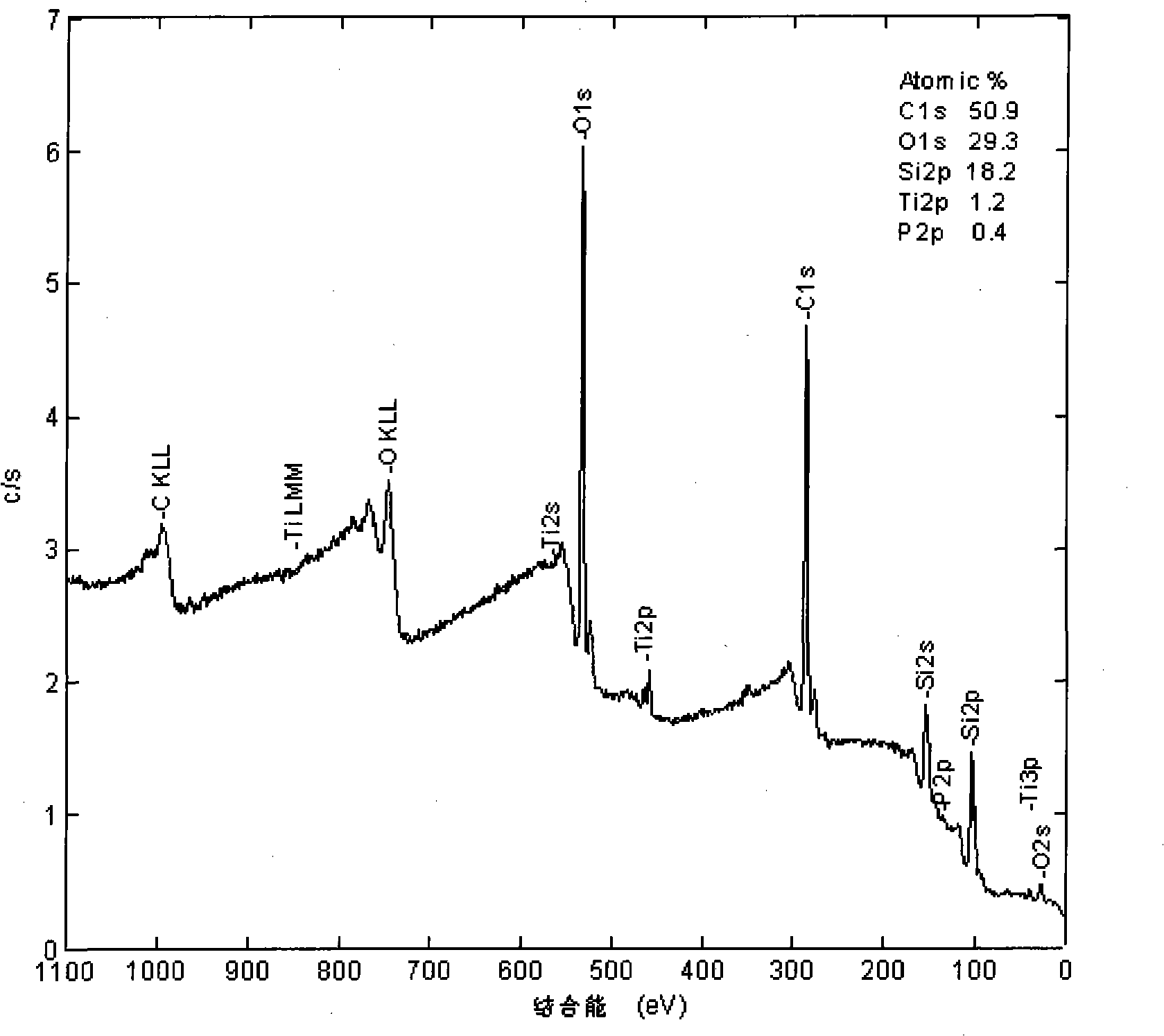

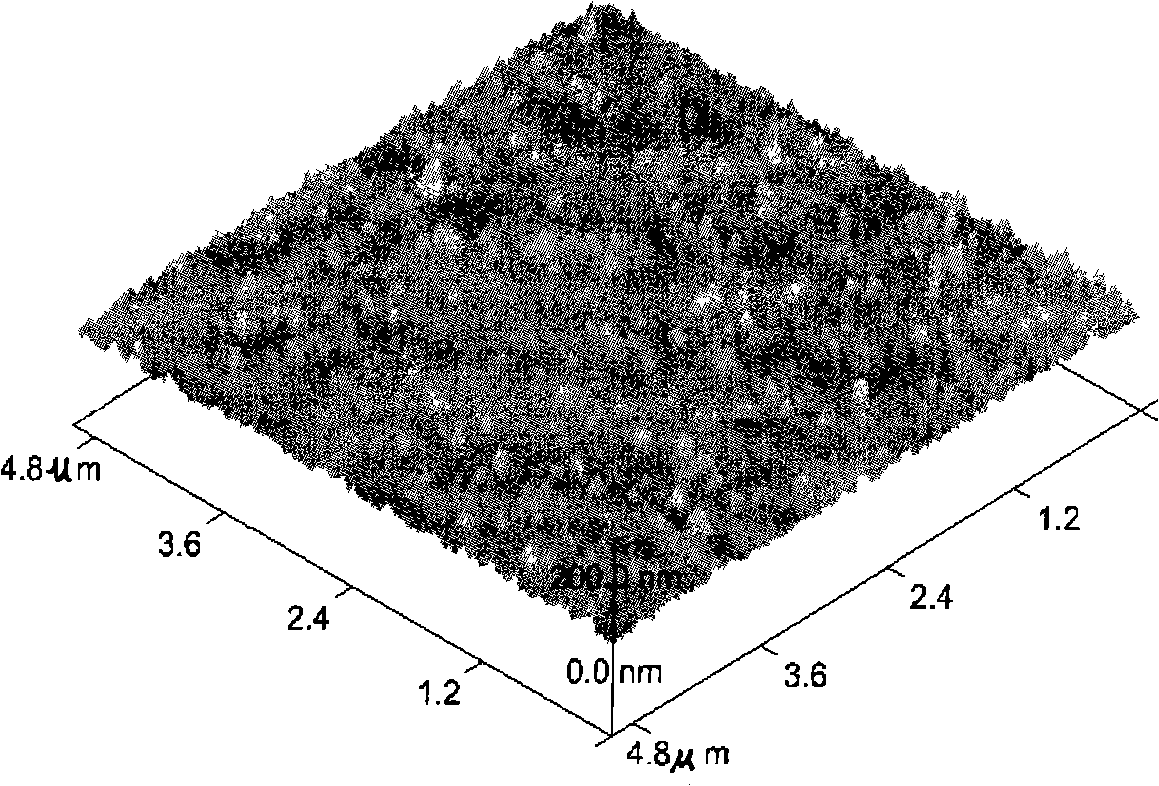

[0022] A method for preparing a titanium dioxide crystalline film at a low temperature, comprising the steps of:

[0023] (1) Clean the monocrystalline silicon wafer; place it in a mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 7:3 and soak it for 20 minutes at 80°C. Drying, vacuum drying at 100°C for 40 minutes;

[0024] (2) With a concentration of 6×10 -3 The anhydrous cyclohexane solution of M mercaptopropyltrimethoxysilane was soaked at room temperature to treat the substrate for 30 minutes, after taking it out, rinsed with cyclohexane and ethanol successively, and dried with nitrogen;

[0025] (3) Prepare supersaturated methanol or aqueous solution of phosphorus pentoxide, put the substrate after the self-assembly treatment of mercaptopropyltrimethoxysilane into it, and react at 40°C for 30 minutes. water for washing and drying;

[0026] (4) Finally put the substrate into 5mM TiCl 4 / 0.1M HCl aqueous solution, deposit at 80°C...

Embodiment 2

[0031] A method for preparing a titanium dioxide crystalline film at a low temperature, comprising the steps of:

[0032] (1) Wash the glass sheet with water, take out the substrate from the washing solution, put it in hydrogen peroxide and soak it at 15°C for 60 minutes, wash the substrate with ethanol after taking it out, and dry it with air;

[0033] (2) The immersion concentration of the substrate treated in step (1) is 1×10 -3 M SHCH 2 Si(OCH 3 ) 3 soak in anhydrous methanol solution at 15°C for 180 minutes, take it out, wash it with cyclohexane and water successively, and dry it with air;

[0034] (3) Soak the substrate obtained after the treatment in step (2) at 15° C. in a supersaturated methanol solution of phosphorus pentoxide for 120 minutes, take out the substrate, wash it with ethanol and water successively, and dry it;

[0035] (4) Immerse the substrate treated in step (3) at 20° C. in an isopropyl titanate ethanol solution with a concentration of 5 mM to dep...

Embodiment 3

[0037] A method for preparing a titanium dioxide crystalline film at a low temperature, comprising the steps of:

[0038] (1) Wash the ceramic sheet with ethanol and water in turn, take out the substrate from the washing liquid, put it in a mixed solution of acetic acid and hydrogen peroxide with a volume ratio of 1.5:1 at 90°C, soak for 10 minutes, and remove the substrate in turn Rinse with distilled water and blow dry with nitrogen;

[0039] (2) immerse the substrate processed through step (1) into a concentration of 5×10 -2 M's SH(CH 2 ) 16 Si(OCH 3 ) 3 soak in anhydrous methanol solution at 50°C for 30 minutes, take it out, wash it with methanol and water successively, and dry it with air;

[0040] (3) Soak the substrate obtained after the treatment in step (2) at 50° C. in a supersaturated ethanol solution of phosphorus pentoxide for 30 minutes, take out the substrate, wash it with ethanol and water successively, and dry it;

[0041](4) Immerse the substrate treate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com