Wood industry adhesive and preparation thereof

An adhesive and wood technology, applied in the direction of adhesives, adhesive types, aldehyde/ketone condensation polymer adhesives, etc., can solve the problems of long curing time, slow bonding speed, poor penetration, etc. Short, fast bonding speed, no arch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

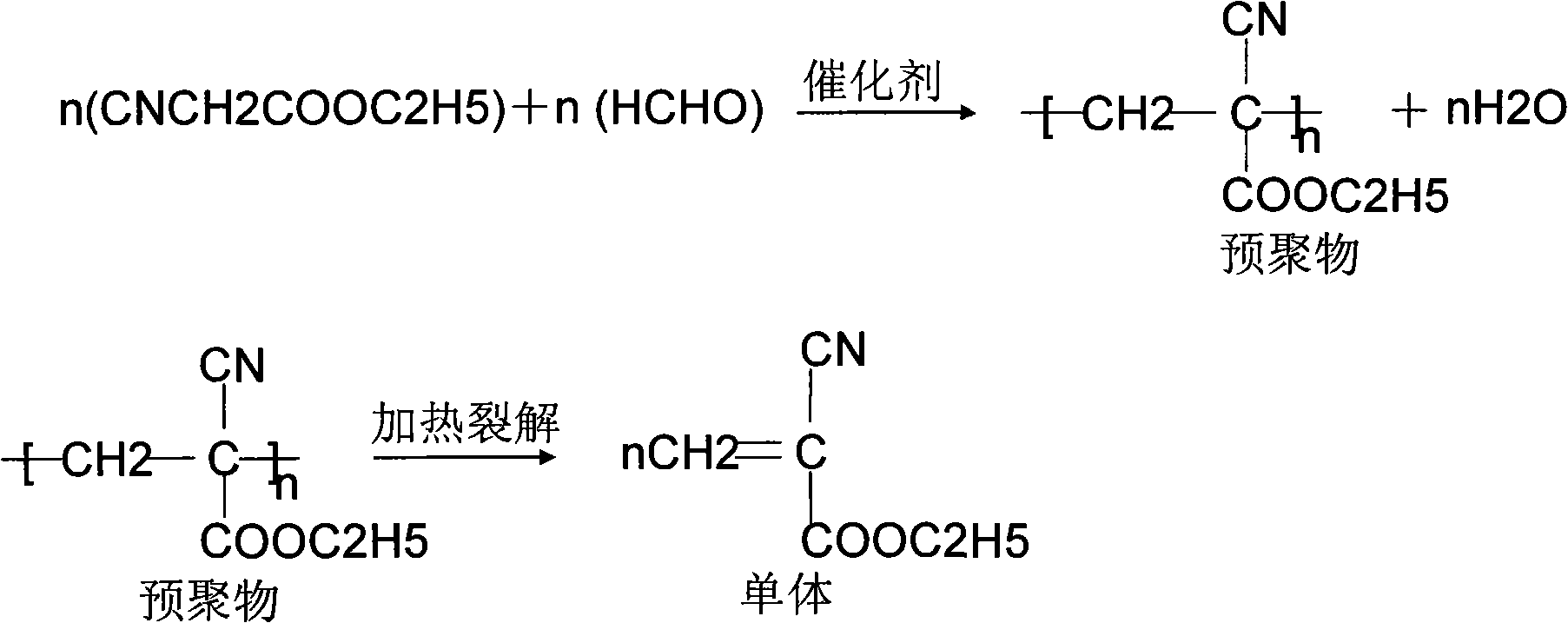

Method used

Image

Examples

Embodiment

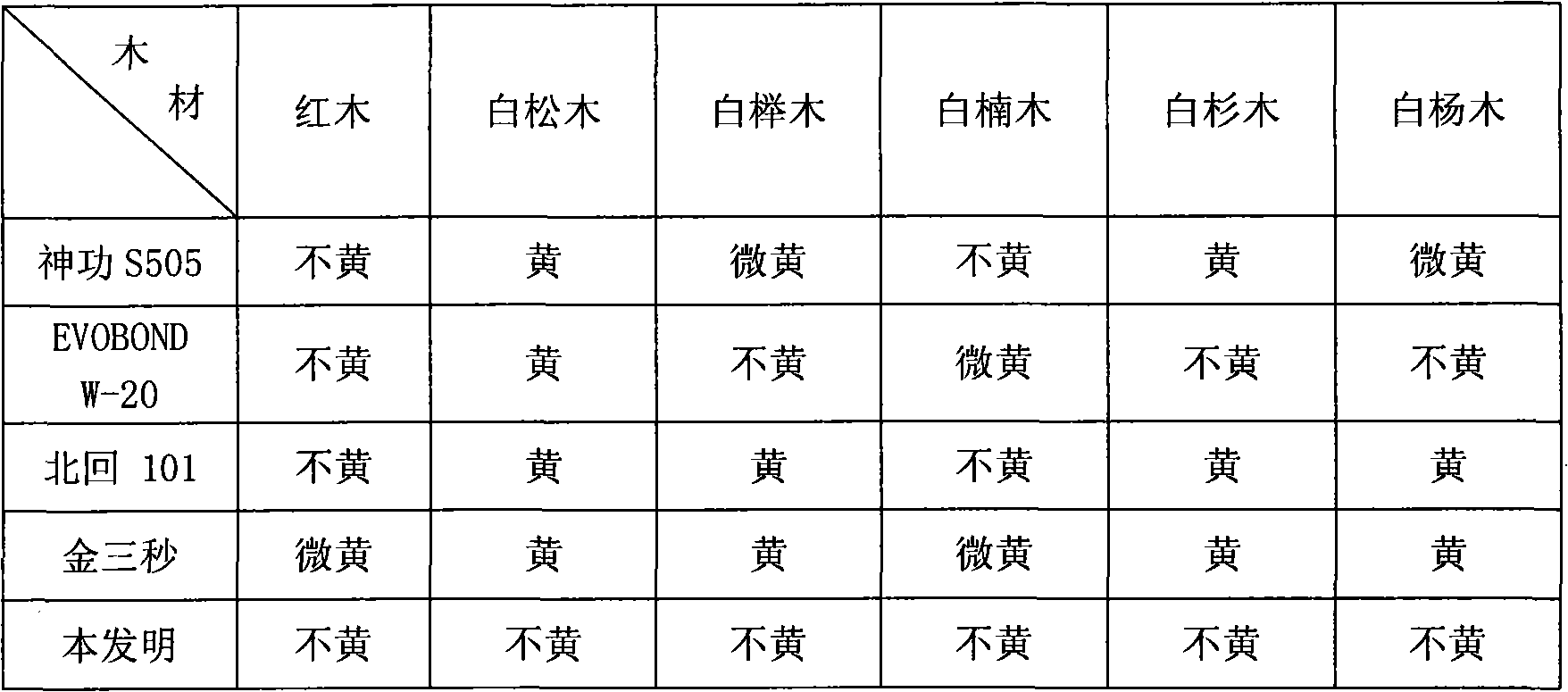

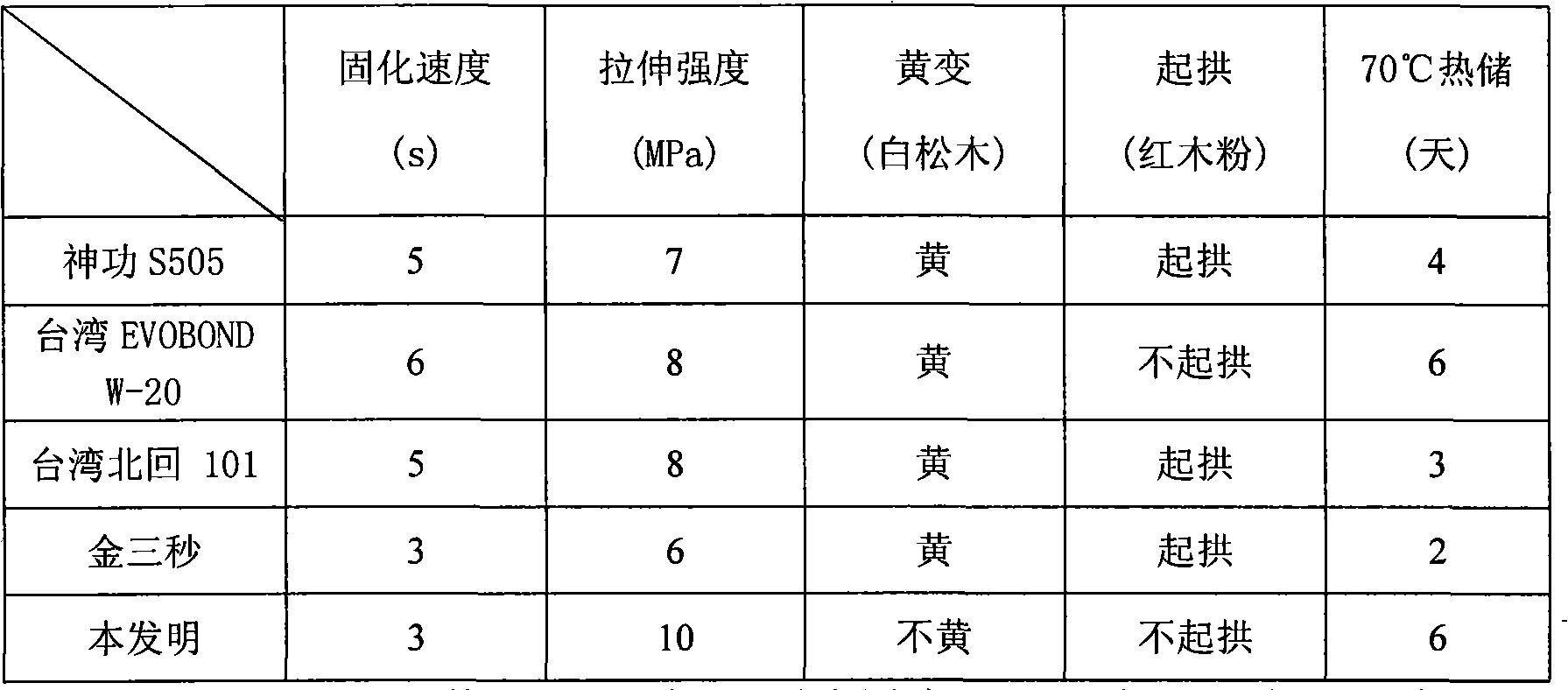

[0030] Embodiment: a kind of wood adhesive, wherein: be made up of following components by weight parts:

[0031] 1 part of paraformaldehyde; 2 to 4.6 parts of dichloroethane; 3 to 4 parts of ethyl ester or / and 10 to 15 parts of hexahydropyridine; 0.03 to 0.54 parts of phosphorus pentoxide and / or terephthalate 0.022 to 0.514 parts of phenol; 0.003 to 0.018 parts of p-toluenesulfonic acid; less than 0.1 parts of additives.

[0032] A preparation method of wood adhesive, wherein: comprising the following steps:

[0033] Polymerization step, cracking step, distillation step and refining step;

[0034] The aggregation steps include:

[0035] Step 1: Select 1 part of paraformaldehyde and mix with 2 to 4.6 parts of dichloroethane in parts by weight;

[0036] Step 2: Add the pre-mixed additive dropwise to the mixture mixed in step 1 at a temperature ranging from 55°C to 63°C, and the time is controlled at most 2 hours; the additive includes 3 to 4 parts of ethyl ester or / and 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com