Plasma display panel, method of manufacturing the same, and composition of partitions thereof

A display panel and plasma technology, applied in the direction of alternating current plasma display panels, cold cathode manufacturing, electrode system manufacturing, etc., can solve the problems of color temperature deterioration, image quality deterioration, panel appearance damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

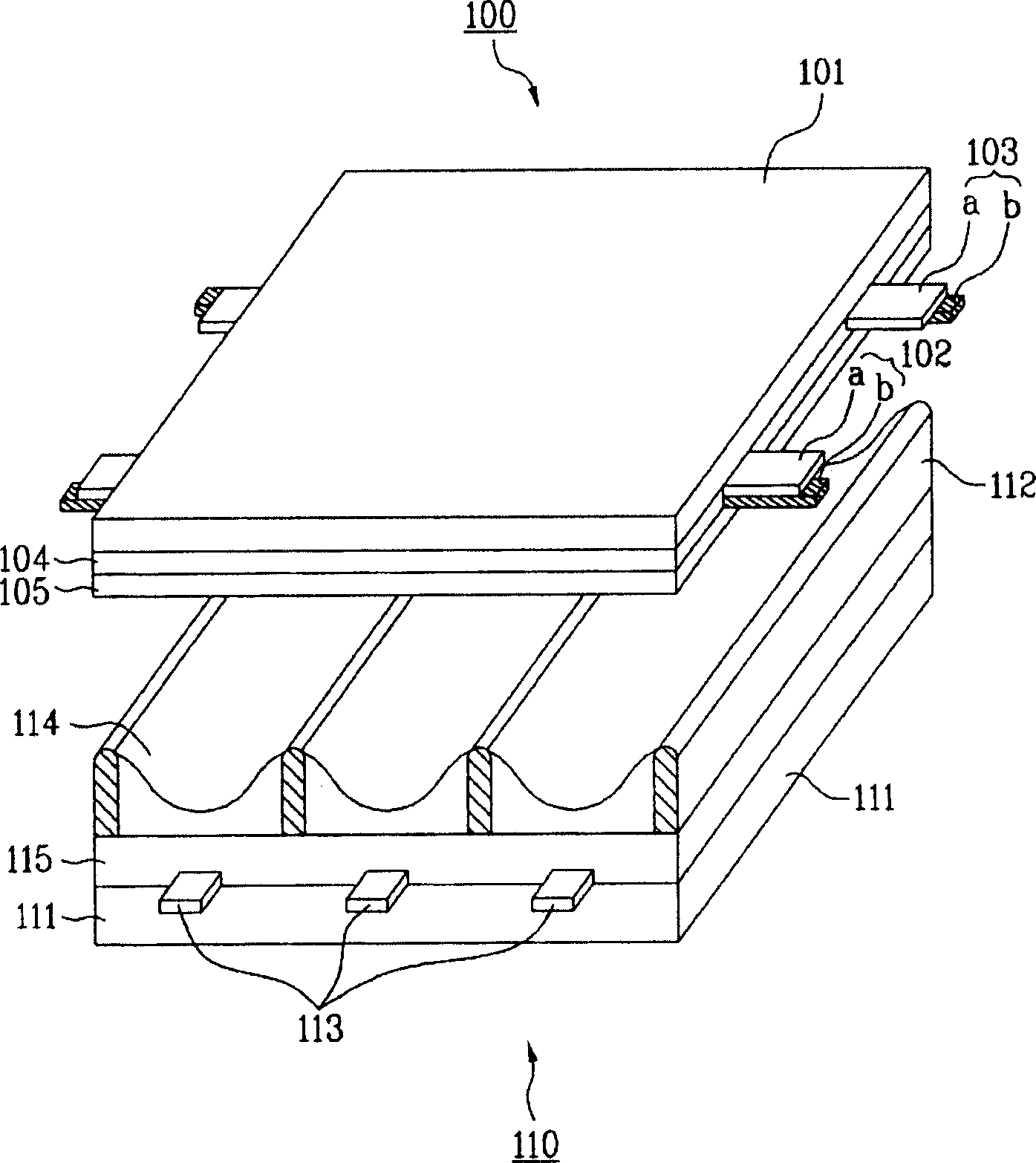

[0032] Preferred embodiments of the plasma display panel, its manufacturing method and the material for the spacer of the plasma display panel of the present invention are described in detail below, in Figures 1 to 9K An example of it is shown in .

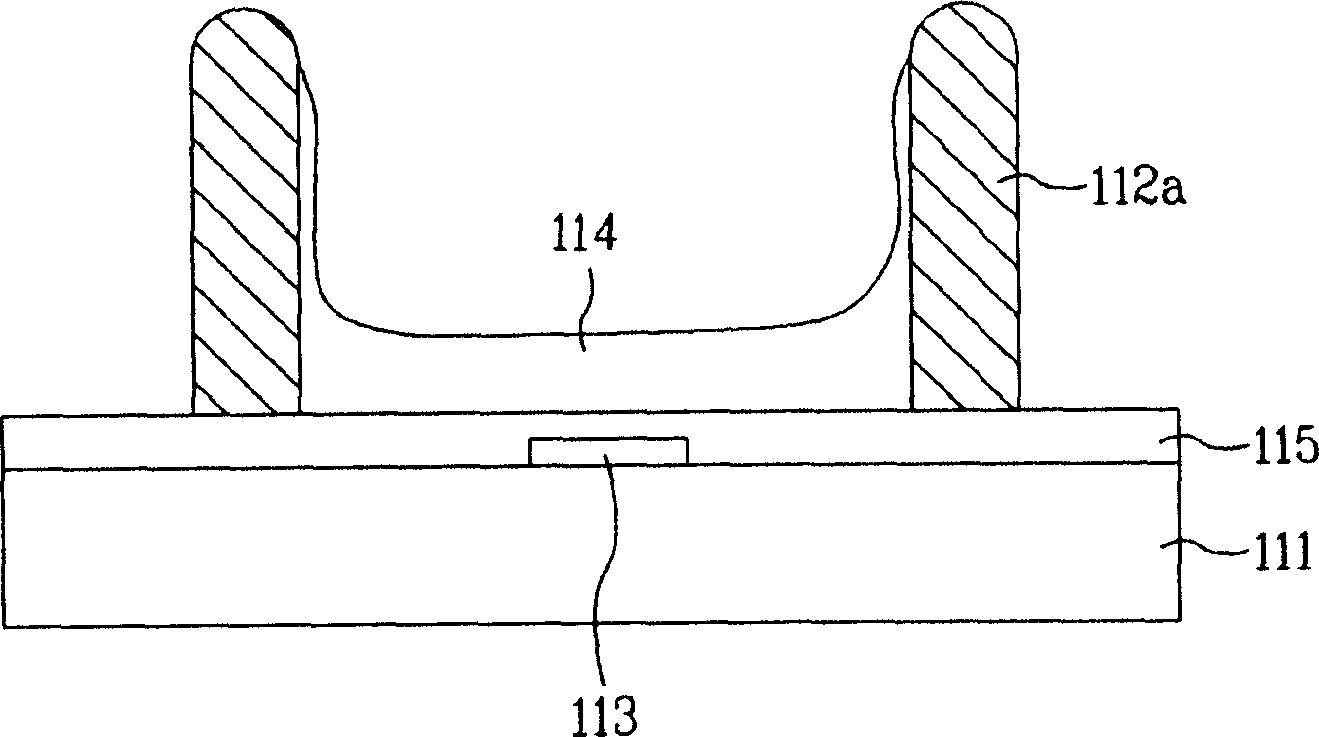

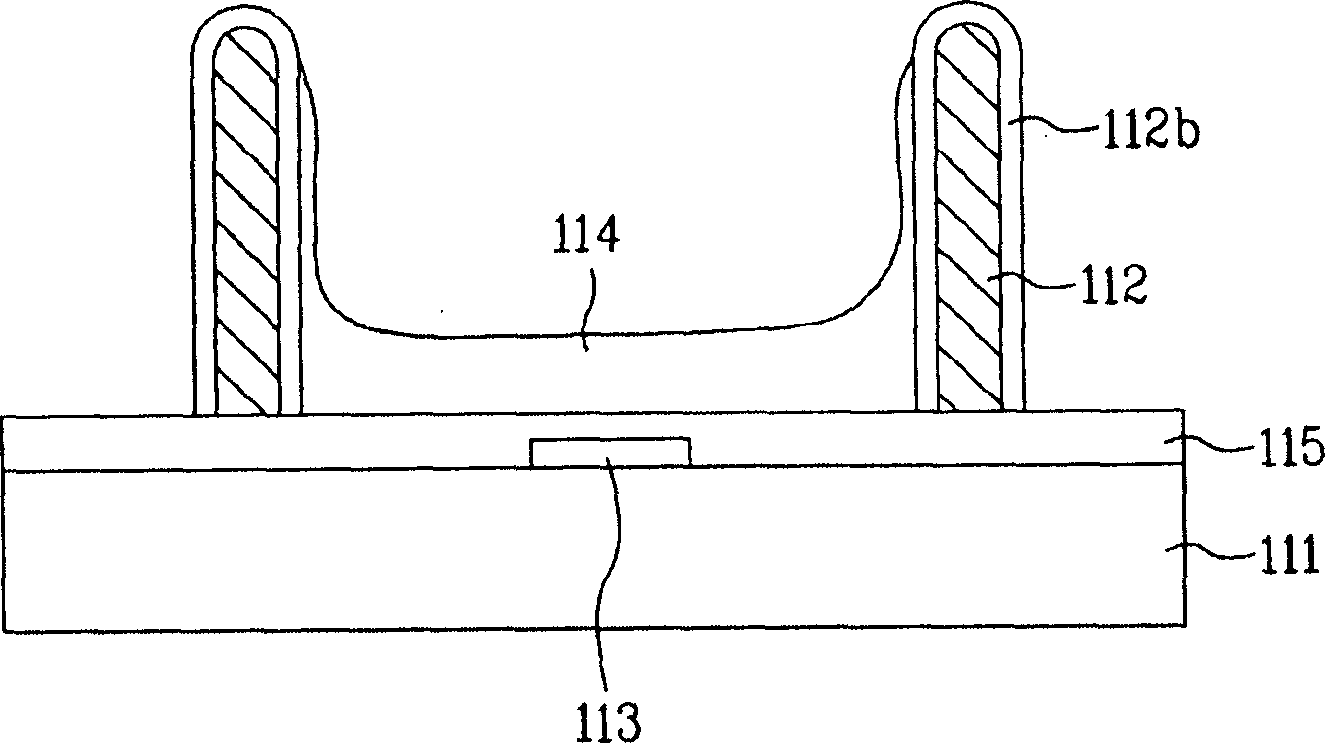

[0033] figure 2 is a cross-sectional view schematically illustrating the rear substrate of the plasma display panel according to the first preferred embodiment of the present invention.

[0034] The front substrate of the plasma display panel according to this preferred embodiment of the present invention has the same structure as the front substrate of the existing plasma display panel, so that a plurality of pairs of sustain electrodes forming scan electrodes and sustain electrode pairs are arranged in the existing plasma display panel. The front substrate of the display panel is on a front glass 101 which is a display surface in which an image is displayed. In the rear substrate, a plurality of address electrodes 113 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com