High-color-rendering composite fluorescent glass and preparation method thereof

A composite fluorescence, high color rendering technology, applied in the field of fluorescent materials, can solve the problems of inability to achieve rapid cooling molding, unfavorable large-scale production, aggravation, etc., achieve excellent thermal stability and chemical stability, and meet the needs of large-scale industrial production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

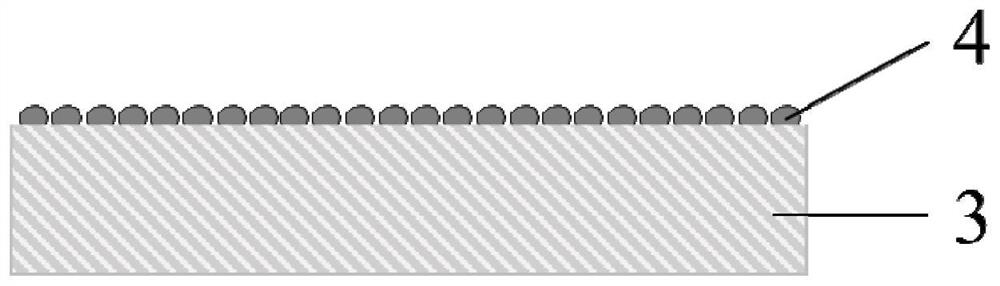

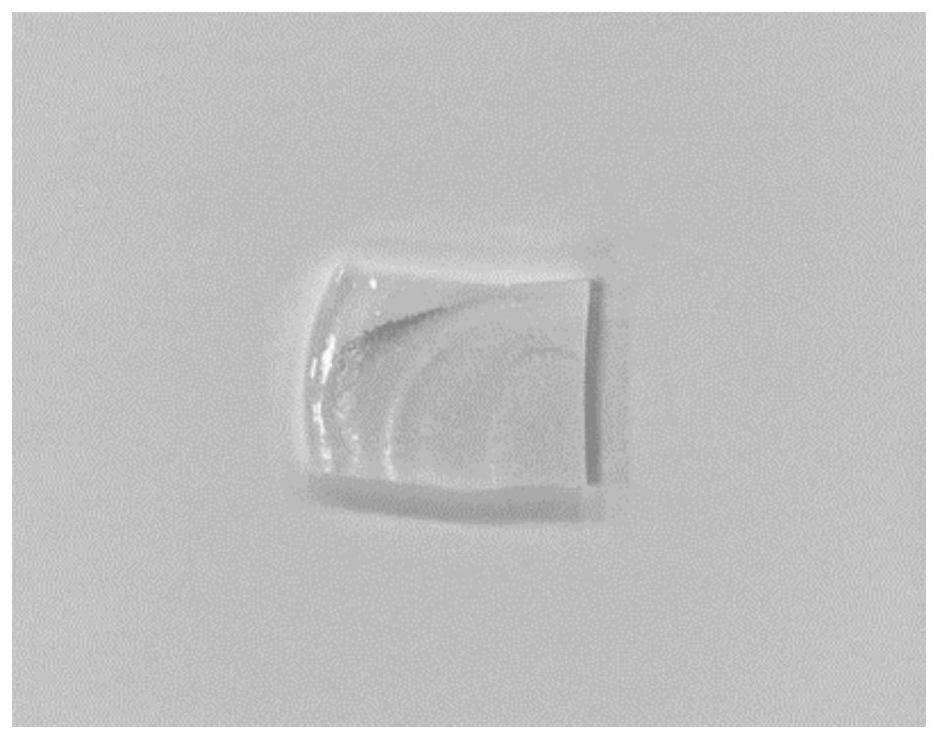

[0033] According to the tellurate glass formula, weigh a certain amount of raw materials, mix them evenly, put them into a crucible, melt them at 850°C for 0.5h, quench the molten glass with water, dry, grind and pass through a 200-mesh sieve to obtain Matrix glass powder. Weigh LuAG:Ce by 8% mass fraction 3+ Green fluorescent powder and matrix glass powder are mixed thoroughly and put into a crucible, melted at 580°C for 0.3h, pour the melt into a copper mold heated to 250°C, and a layer of CaAlSiN has been laid on the bottom of the mold in advance 3 :Eu 2+ red phosphor. After the melt in the crucible flows into the mold completely, quickly cover the mold tightly. Continue to keep warm for 0.5h, after it is naturally cooled to room temperature, it is taken out from the mold, annealed at 320°C for 3h, and the composite fluorescent glass material is obtained after cooling to room temperature.

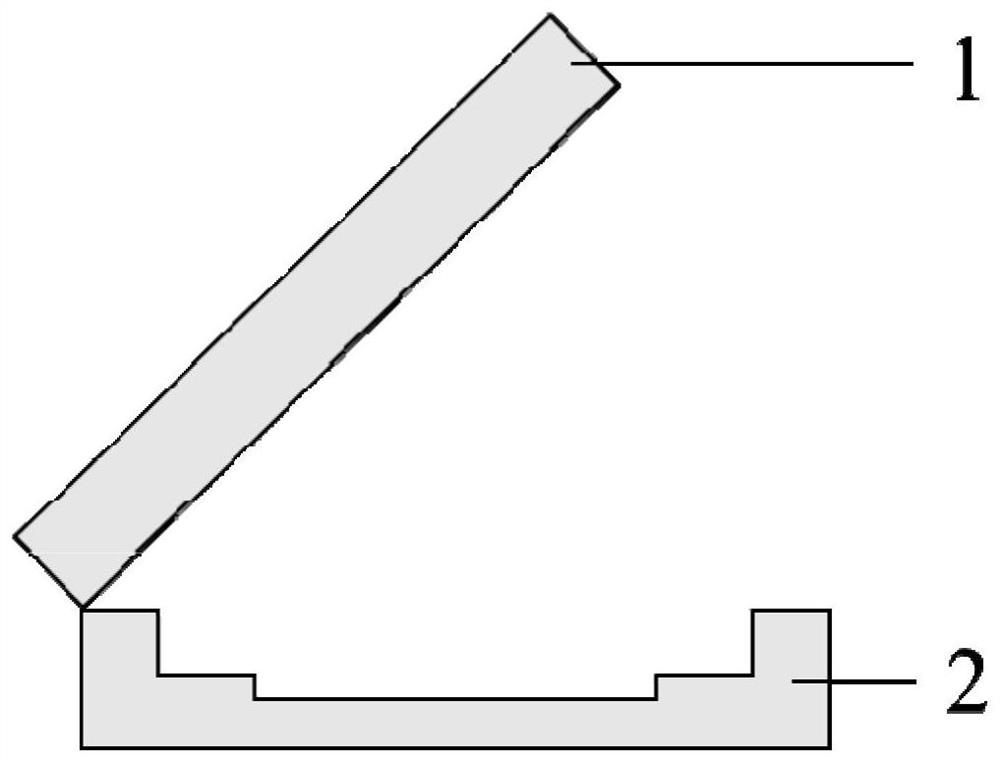

[0034] The structure diagram of the mold is shown in figure 2 As shown, it inc...

Embodiment 2

[0042]According to the phosphate glass formula, weigh a certain amount of raw materials, mix them evenly, put them into a crucible, melt them at 1000°C for 1 hour, quench the molten glass with water, dry, grind and pass through a 200-mesh sieve to obtain matrix glass pink. Weigh YAG:Ce by 20% mass fraction 3+ Mix yellow fluorescent powder and matrix glass powder thoroughly, put them into a crucible, melt at 650°C for 0.5h, pour the melt into a copper mold heated to 250°C, and a layer of CaAlSrN has been laid on the bottom of the mold in advance 3 :Eu 2+ red phosphor. After the melt in the crucible flows into the mold completely, quickly cover the mold tightly. Continue to keep warm for 0.5h, after it is naturally cooled to room temperature, it is taken out from the mold, annealed at 320°C for 3h, and the composite fluorescent glass material is obtained after cooling to room temperature.

Embodiment 3

[0044] According to the formula of borate glass, weigh a certain amount of raw materials, mix them evenly, put them into a crucible, melt them at 1100°C for 1 hour, quench the molten glass with water, dry, grind and pass through a 200-mesh sieve to obtain the matrix glass powder. Weigh YAGG:Ce by 15% mass fraction 3+ Green fluorescent powder and matrix glass powder are mixed thoroughly and put into a crucible, melted at 700°C for 1 hour, pour the melt into a copper mold heated to 200°C, and a layer of K has been laid on the bottom of the mold in advance 2 SiF 6 :Mn 4+ red phosphor. After the melt in the crucible flows into the mold completely, quickly cover the mold tightly. Continue to keep warm for 0.5h, after it is naturally cooled to room temperature, it is taken out from the mold, annealed at 320°C for 3h, and the composite fluorescent glass material is obtained after cooling to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com