Measuring method for mold clearance of plate molding of plate type heat exchanger

A technology for plate heat exchangers and forming molds, which is applied to measuring devices, instruments, etc., can solve problems such as inaccurate measurement of mold gaps and waste of production materials, and achieve the effects of simple detection methods, good fluidity, and waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention and its beneficial effects will be further described in detail below in conjunction with the accompanying drawings.

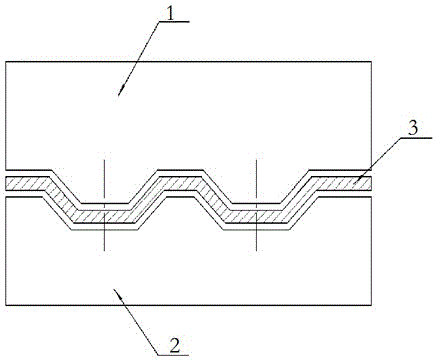

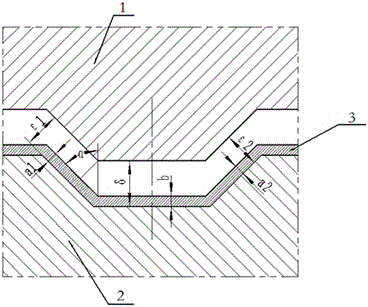

[0027] Such as Figure 1 to Figure 3 Shown is a method for measuring the gap between plate forming molds for plate heat exchangers. This method uses soft metal materials to be placed at the gaps to be detected by the mold to be tested. After the mold is closed, the soft metal material deforms. By measuring the deformation of the soft metal To judge the clearance of the mold under test, it includes the following steps:

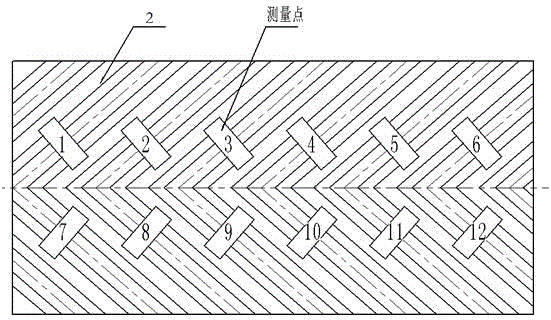

[0028] Step 1. Cut the lead wire or tin wire of soft metal material into several small pieces, prepare soft metal samples, and place 1 to 12 test points on the inner surface of the lower mold of the mold test point. The test points are evenly, comprehensively and symmetrically distributed. on the inner surface of the die;

[0029] Step 2. Sample forming. After placing the soft metal sample properly, close the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com