Lanthanum-aluminum phosphate composite material cured at normal pressure and low temperature as well as preparation method and application thereof

A composite material and phosphate technology, which is applied in the field of lanthanum-aluminum phosphate composite materials, can solve problems such as material melting and destruction, and achieve energy saving, low cost, and improved ablation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The invention provides a preparation method of a lanthanum-aluminum phosphate composite material, comprising the following steps:

[0078] 1) After the preheated dilute phosphoric acid and aluminum hydroxide are reacted, a transparent solution is obtained;

[0079] 2) Mix the transparent solution and chromium trioxide obtained in the above steps, then add hydrogen peroxide, and conduct a heating reaction to obtain aluminum chromium phosphate-based mucus;

[0080] 3) Stir and gel the aluminum-chromium-phosphate-based slime and lanthanum oxide obtained in the above steps, and then place them in a mold to solidify to obtain a lanthanum-aluminum phosphate composite material.

[0081] In the invention, the preheated dilute phosphoric acid and aluminum hydroxide are reacted to obtain a transparent solution.

[0082] In the present invention, the preheating temperature is preferably 80-85°C, more preferably 81-84°C, more preferably 82-83°C.

[0083] In the present invention,...

Embodiment 1

[0122] Add 60-80ml of distilled water to 0.8-1mol of H 3 PO 4 (analytical pure), put the diluted phosphoric acid in a water bath at 80-85°C to heat and stir; then add 0.2-0.4mol of Al(OH) 3 Add to the preheated dilute phosphoric acid and stir until the solution has a certain viscosity. At this time, 0.1-0.2mol of CrO 3 Add the above solution and wait for CrO 3 Dissolve immediately add 0.1-0.2mol of H 2 o 2 . Then the mixture was stirred for 20-30 minutes to prepare the aluminum chromium phosphate-based adhesive. Finally weighed 30 parts of La 2 o 3 Mix it with aluminum chromium phosphate, stir continuously in a water bath at 80-85°C until it reaches a suitable viscosity, pour it into a suitable mold, and put it in a 50°C oven to dry and solidify for 1-2 hours to obtain a 30% La-Al series phosphate high temperature resistant material .

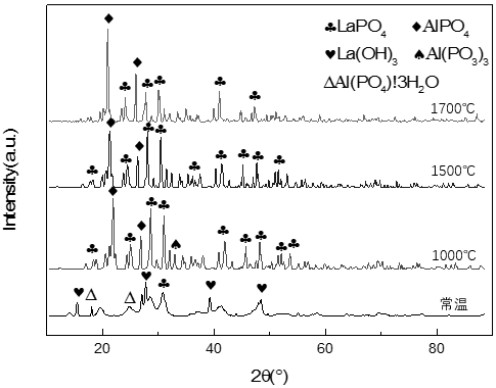

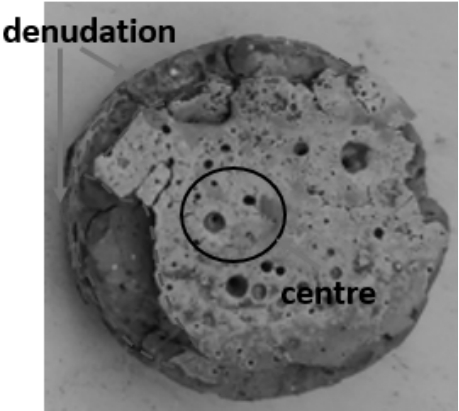

[0123] The lanthanum-aluminum phosphate composite material prepared in Example 1 of the present invention was tested for high temper...

Embodiment 2

[0144] Add 60-80ml of distilled water to 0.8-1mol of H 3 PO 4 (analytical pure), put the diluted phosphoric acid in a water bath at 80-85°C to heat and stir; then add 0.2-0.4mol of Al(OH) 3 Add to the preheated dilute phosphoric acid and stir until the solution has a certain viscosity. At this time, 0.1-0.2mol of CrO 3 Add the above solution and wait for CrO 3 Dissolve immediately add 0.1-0.2mol of H 2 o 2 . Then the mixture was stirred for 20-30 minutes to prepare the aluminum chromium phosphate-based adhesive. Finally weighed 30 parts of La 2 o 3 Mix it with aluminum chromium phosphate, stir continuously in a water bath at 80-85°C until it reaches a suitable viscosity, pour it into a suitable mold, and put it in a 50°C oven to dry and solidify for 1-2 hours to obtain a 40% La-Al series phosphate high temperature resistant material .

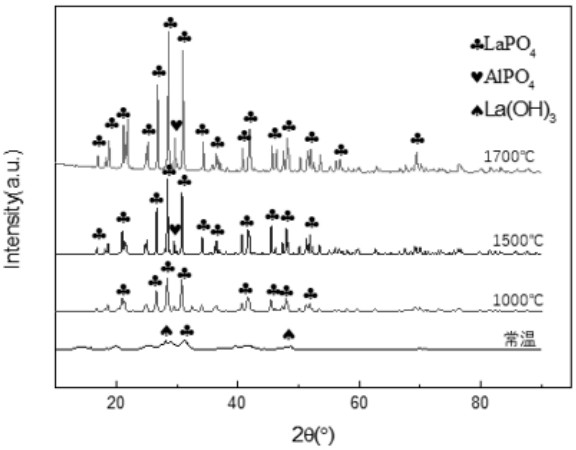

[0145] The lanthanum-aluminum phosphate composite material prepared in Example 2 of the present invention was tested for high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com