Sand lined metal mould casting brake shoe tool device and production method thereof

A technology for iron mold sand-coated casting and brake shoes, which is applied in the field of foundry tooling devices and iron mold sand-coated casting brake shoes, can solve the problems of low production efficiency and achieve improved production efficiency, uniform material, and structural well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

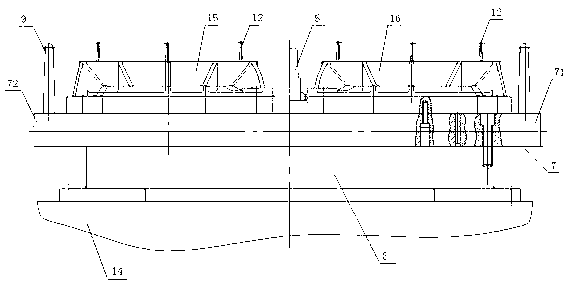

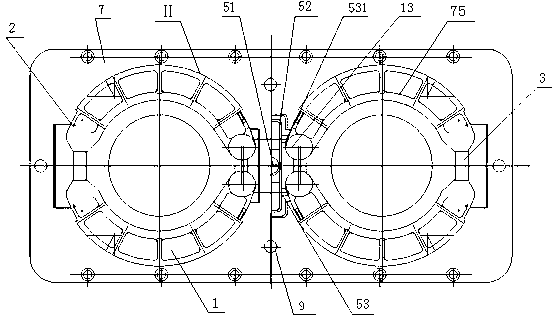

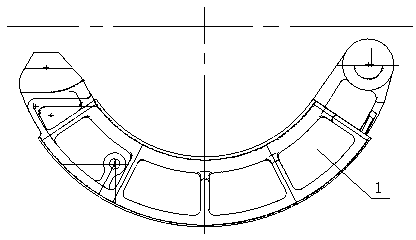

[0032] see Figure 1 to Figure 9 , the present invention mainly includes lower casting 1, upper casting 2, overall casting II, connecting plate 3, mud core 4, pouring system 5, iron mold 6, mold plate 7, base 8, positioning pin 9, box buckle 10.

[0033] The lower casting 1, the upper casting 2 and the overall casting II are all installed on the template 7, the lower casting 1 and the upper casting 2 are connected with the connecting plate 3 to form an integral casting II, and the mud core 4 is connected with a mud core head 74, and the mud core 4 The core 4 is placed in the iron mold cavity 73, the mud core 4 is used to form the inner cavity 75, the gate nest 54 and the lower part of the runner 55 of the integral casting II, and the ingate 531 is arranged in the ingate 53, and the inflow One end of the port 531 is connected to the runner 52, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com