Dual-zone turbine for turbocharging

A turbocharged, dual-zone technology, applied in stators, engine components, machines/engines, etc., can solve the problems of turbine efficiency reduction, sudden gas expansion, etc., and achieve good inheritance, high casting yield, and high structural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

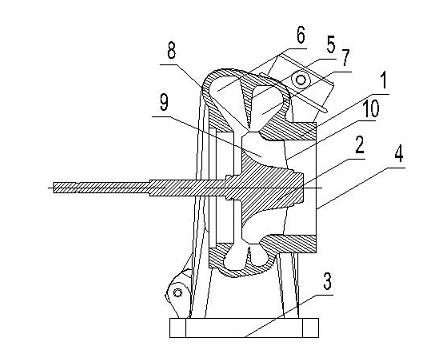

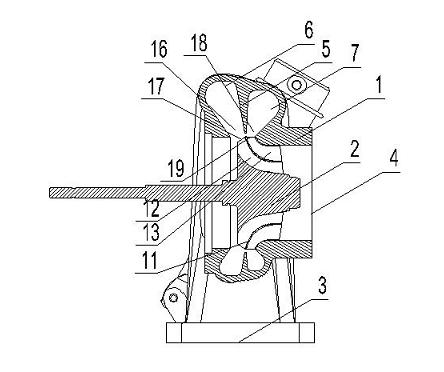

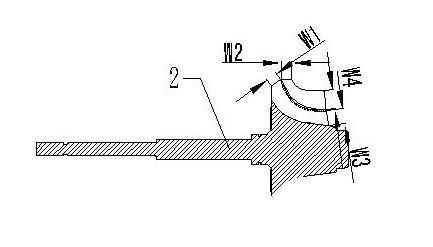

[0043] Example 1, such as figure 2 , image 3 As shown, a dual-zone turbine for turbocharging includes a turbine volute 1, a turbine impeller 2 is installed in the turbine volute 1, and turbine blades are arranged on the outside of the turbine volute 2, and the turbine volute is provided with There are volute air inlet 3, volute air inlet flow channel and volute air outlet 4.

[0044] The turbine wheel 2 is provided with a turbine wheel air inlet, a turbine wheel air intake channel, a turbine wheel air outlet and a turbine wheel blade.

[0045] Between the turbine wheel inlet and the turbine wheel air outlet of the turbine wheel 2, there is a circumferentially arranged partition plate 11, the shape of the partition plate 11 meets the requirements of aerodynamic performance and reliability.

[0046] The partition plate 11 divides the turbine wheel air intake channel into a turbine wheel air intake inner channel 12 and a turbine wheel air intake outer channel 13 .

[0047] T...

Embodiment 2

[0058] Example 2, such as Figure 6 As shown, on the basis of Embodiment 1, the adjustable valve 20 near the volute inlet 3 in the left flow passage 6 of the volute air intake is removed, and the right flow passage 7 of the volute air intake is close to the volute An adjustable valve 20 is provided at the air inlet 3 of the shell, and the adjustable valve 20 is connected with the control mechanism, and the rotation of the adjustable valve 20 is realized under the drive of the control mechanism, thereby opening the flow channel 7 on the right side of the volute air intake and off.

[0059] When the engine is in the range of low-speed operating conditions, the amount of exhaust gas discharged by the engine is small, and the adjustable valve 20 is in a closed state driven by the control mechanism, so the right side flow channel 7 of the volute intake and the intake air of the outer flow channel of the turbine impeller intake Port 19, turbine impeller air inlet outer flow channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com