Composite treatment method of regenerated deformed aluminum alloy melt

A technology of deformed aluminum alloy and composite treatment, applied in the direction of improving process efficiency, can solve problems such as performance decline, process yield reduction, complex composition, etc., and achieve the effect of reducing crack sources, broadening industrial applications, and comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

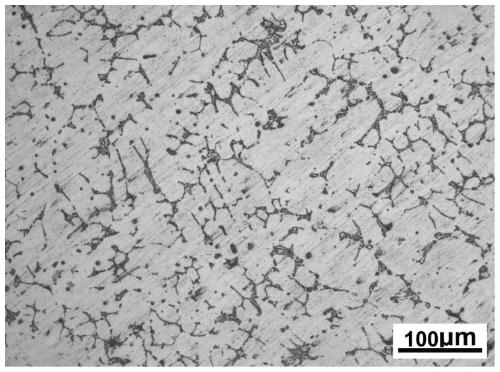

Embodiment 1

[0054] Preparation of 6xxx series regenerated deformed aluminum alloy treated with Mg / Sr / C-containing refining agent: According to the method of Comparative Example 1, melted 6xxx series recycled scrap aluminum after preliminary screening, the initial basic composition is the same as that of Comparative Example 1, stripped off The slag is kept warm and kept for 20 minutes. Add Mg ingot, Al-10Sr modifier and Al-5Ti-0.3B-0.2C refiner to the melt, keep the melt temperature at 720℃, stir evenly after melting, keep it at rest for 20 minutes; among them, Al-10Sr is degraded The addition amount of the agent is 0.6% of the melt mass, and the addition amount of Al-5Ti-0.3B-0.2C refiner is 0.7% of the melt mass. After the Mg ingot is added, the mass percentage of Mg in the melt is adjusted to 1.2%. The melt was refined and slag-removed according to the method of Comparative Example 1, and the refining and slag-removed melt was cast into an ingot. Subsequently, the ingot was placed in a...

Embodiment 2

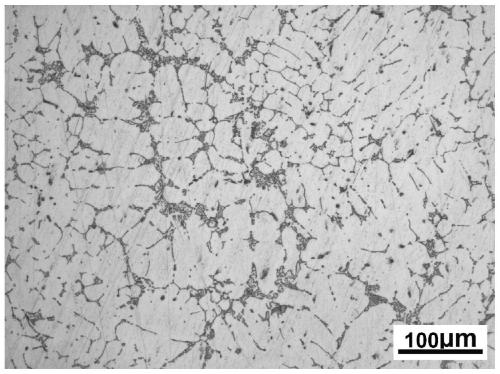

[0057] Preparation of 6xxx series regenerated deformed aluminum alloy treated with Mg / Sr / C-containing refining agent: The preparation method of this embodiment 2 is similar to that of embodiment 1, except for the Mg ingot, Al-10Sr modifier and Al The addition amount of -5Ti-0.3B-0.2C refiner is different. In this example 2, the amount of Al-10Sr modifier added is 0.6% of the melt mass, and the amount of Al-5Ti-0.3B-0.2C refiner added is 0.3% of the melt mass. Mg ingots are added and melted. The mass percentage of Mg in the body is adjusted to 1.0%.

[0058] The optical microstructure of the regenerated deformed aluminum alloy prepared in this example is similar to the microstructure of the regenerated deformed aluminum alloy prepared in Example 1, but the eutectic structure of this example is reduced, and needle-like dendrites are broken. In the as-cast state, the thermal crack sensitivity coefficient HTS of the alloy of this example is 130, the tensile strength is 207.3 MPa, th...

Embodiment 3

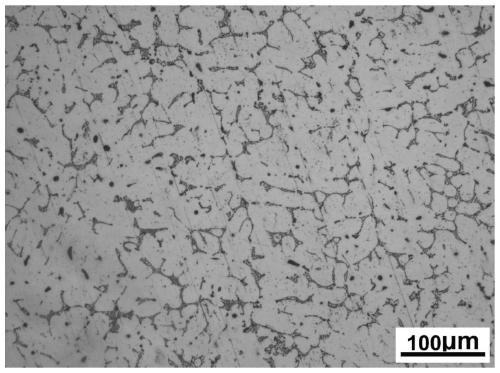

[0060] Preparation of 6xxx series regenerated deformed aluminum alloy treated with Mg / Sr / C-containing refining agent: The preparation method of this embodiment 3 is similar to that of embodiment 1, except that Mg ingot, Al-10Sr modifier and Al The addition amount of -5Ti-0.3B-0.2C refiner is different. In Example 3, the addition amount of Al-10Sr modifier is 0.2% of the melt mass, and the addition amount of Al-5Ti-0.3B-0.2C refiner is 0.5% of the melt mass. The Mg ingot is added and melted. The mass percentage of Mg in the body is adjusted to 1.2%.

[0061] The optical microstructure of the regenerated deformed aluminum alloy prepared in this example is similar to that of the regenerated deformed aluminum alloy prepared in Example 1. The grains are refined, and the eutectic structure is distributed in dots or blocks at the grain boundaries. around. In the as-cast state, the thermal crack sensitivity coefficient HTS of the alloy of this example is 126, the tensile strength is 21...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com