Low alloy steel

A low-alloy steel and process technology, used in metal processing equipment, coating, casting and molding equipment, etc., can solve the problems of large cracking and deformation, poor toughness, large grain size of castings, etc., and achieve high fatigue strength and good toughness. , the effect of high casting yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

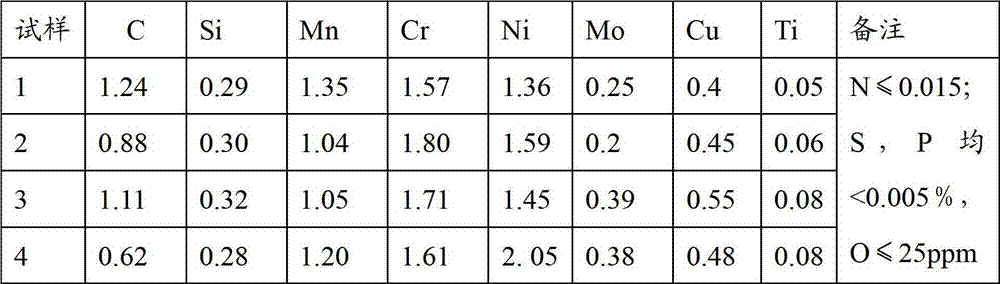

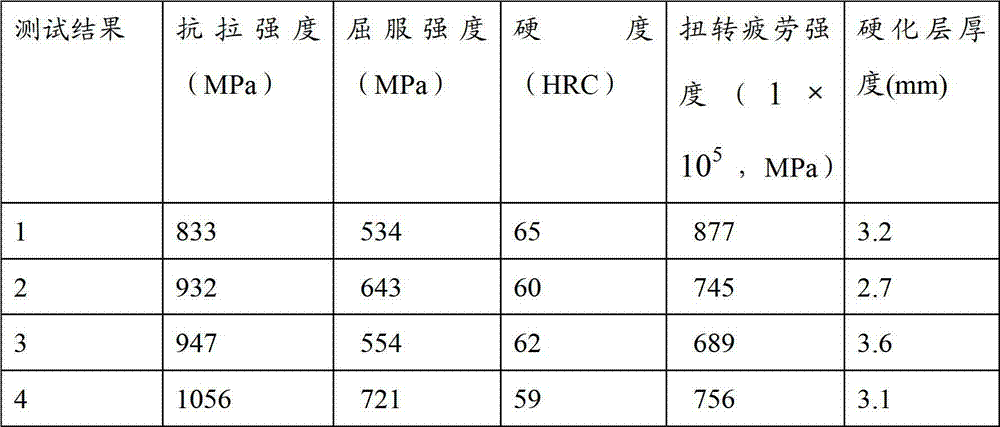

[0048] The low-alloy steel of the present invention is smelted in a vacuum induction furnace, and its specific chemical composition is shown in Table 1.

[0049] Table 1 Chemical Composition List

[0050]

[0051] Gears are then prepared as follows:

[0052] 1) Make pattern with foam material, the tooth shape of pattern is consistent with the tooth-shaped parts; Apply adhesive on the surface of pattern, sandblast and dry; The sandblasting is silicon carbide; The adhesive is polyacrylamide; The pattern is placed in the sand box, the sprue is placed, sand is filled into the sand box for modeling, and a riser is set on the pattern; the alloy material is smelted; the melting temperature is 1620°C, and the pouring temperature is 1530°C; pouring; after cooling, open the box Shakeout to clean the castings;

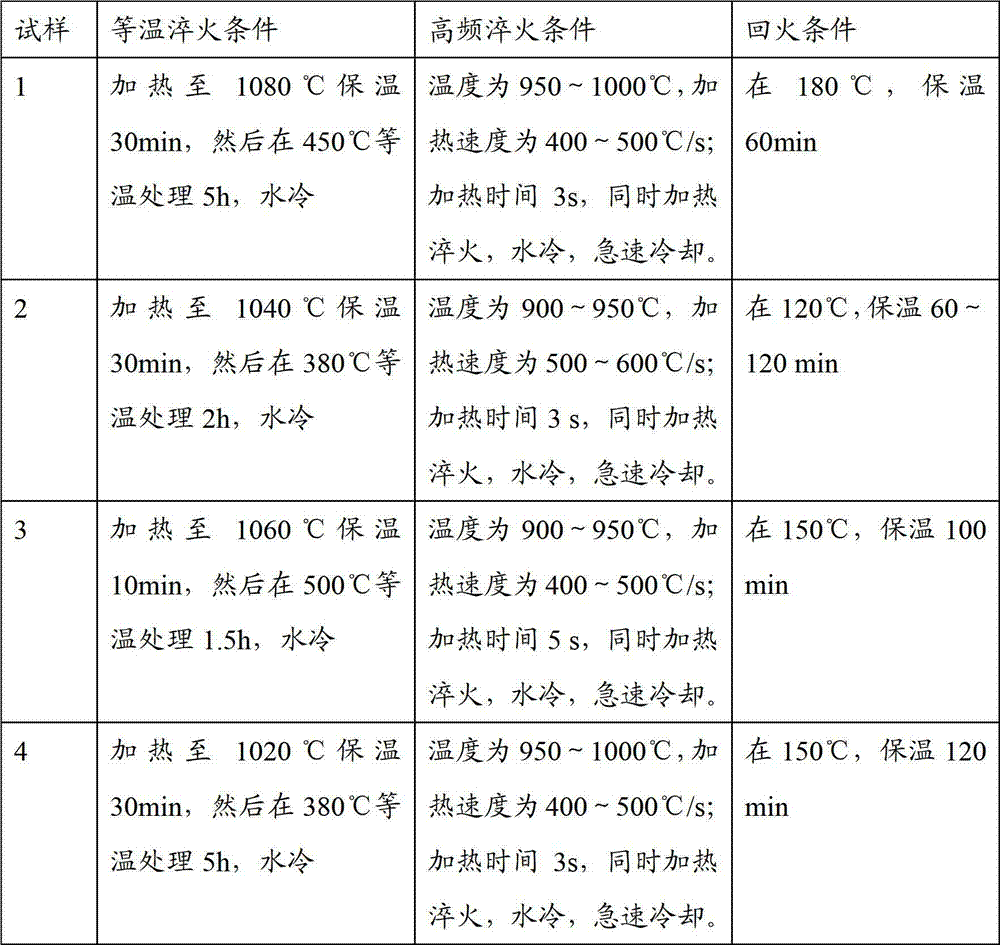

[0053] 2) Austempering is carried out after the above-mentioned cast casting is processed, and then high-frequency quenching is carried out;

[0054] 3) Quenching the heate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com