High-carbon equivalent and high-strength gray cast iron and preparation method thereof

A high-carbon equivalent, high-strength technology, applied in the field of high-carbon-equivalent, high-strength gray cast iron, can solve problems such as nitrogen pore defects that are prone to occur, and achieve the effects of reducing the tendency of material shrinkage and porosity, good thermal conductivity, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

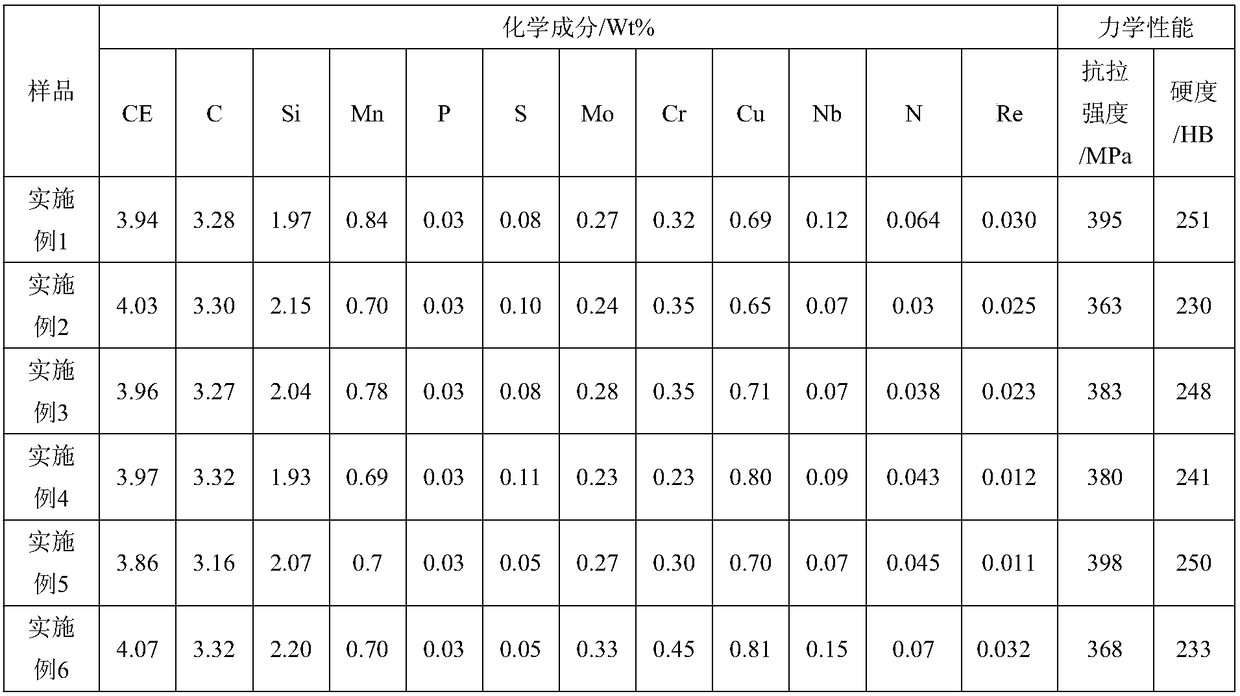

Examples

preparation example Construction

[0020] A method for preparing gray cast iron with high carbon equivalent and high strength, comprising the following steps:

[0021] (1) Alloy smelting: use intermediate frequency smelting furnace for smelting, and the furnace materials are pig iron, scrap steel, recycled material, ferromanganese, ferro-niobium, ferrochrome, copper, ferrosulfur, ferromolybdenum, recarburizer, iron nitride alloy, according to the furnace The chemical composition is adjusted according to the test results of the molten iron composition. When the temperature of the molten iron reaches 1470 ° C ~ 1560 ° C, it is allowed to stand for 5 ~ 25 minutes, and then it is taken out of the furnace;

[0022] (2) Inoculation treatment: pour molten iron into the ladle for inoculation treatment, sprinkle slag collecting agent, and pour;

[0023] (3) Pouring: The inoculated molten iron is poured at a temperature of 1360°C to 1440°C, and an inoculant is added to inoculate with the flow while pouring, and the inocu...

Embodiment 1

[0044] A high-carbon equivalent high-strength gray cast iron of the present invention, the composition and weight percentage of the gray cast iron are: C: 3.25%, Si: 1.97%, Nb: 0.08%, N: 0.054%, Mn: 0.84%, P : 0.03%, S: 0.08%, Cu: 0.69%, Cr: 0.32%, Mo: 0.27%, Re: 0.03%, and the balance is Fe and unavoidable impurities.

[0045] The carbon equivalent (CE) in the high-carbon-equivalent high-strength gray cast iron is 3.94%.

[0046] A method for preparing gray cast iron with high carbon equivalent and high strength, comprising the following steps:

[0047] (1) Alloy smelting: use intermediate frequency smelting furnace for smelting, and the furnace materials are pig iron, scrap steel, recycled materials, ferromanganese, ferro-niobium, ferrochrome, copper, iron sulfur, ferromolybdenum, coke, iron nitride alloy, according to the molten iron in the furnace The chemical composition is adjusted according to the composition test results. When the temperature of the molten iron reache...

Embodiment 2

[0055] A high-carbon equivalent high-strength gray cast iron of the present invention, the composition and weight percentage of the gray cast iron are: C: 3.3%, Si: 2.15%, Nb: 0.07%, N: 0.03%, Mn: 0.7%, P : 0.03%, S: 0.03%, Cu: 0.65%, Cr: 0.35%, Mo: 0.24%, Re: 0.025%, and the balance is Fe and unavoidable impurities.

[0056] The carbon equivalent (CE) in the high-carbon-equivalent high-strength gray cast iron is 4.03%.

[0057] A method for preparing gray cast iron with high carbon equivalent and high strength, comprising the following steps:

[0058] (1) Alloy smelting: use intermediate frequency smelting furnace for smelting, and the furnace materials are pig iron, scrap steel, recycled materials, ferromanganese, ferro-niobium, ferrochromium, copper, iron sulfur, ferromolybdenum, anthracite, iron nitride alloy, according to the molten iron in the furnace The chemical composition is adjusted according to the composition test results. When the temperature of the molten iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com