Large-diameter thin-wall silver-copper alloy collector ring and manufacturing method thereof

A production method and technology of silver-copper alloy, which are applied in the manufacturing of slip rings, current collectors, electrical components, etc., can solve the problems of large waste, low yield and high energy consumption, and achieve uniform material, good performance and reasonable annealing temperature control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

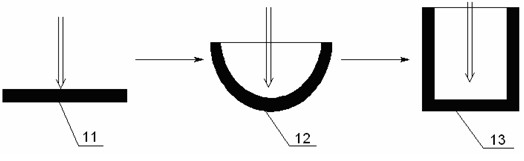

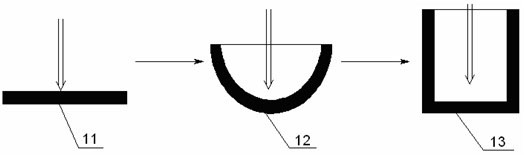

[0024] refer to figure 1 , AgCuNi 20-2 The silver-copper-nickel alloy of the brand is melted into a square ingot in a vacuum intermediate frequency furnace, and then rolled into a square plate 11 with a thickness of 4.6mm and a side length of 450mm, and then annealed in a box-type resistance furnace at an annealing temperature of 650°C and a holding time of 50min .

[0025] The 400-ton two-way hydraulic press exerts pressure on the plate, the periphery of the plate is fixed, and the center moves downward to form a C-shaped concave structure 12 in section.

[0026] Continue to apply pressure to roll the C-shaped concave structure 12 into a long tube 13 with a U-shaped cross-section. The low end of the long tube 13 is closed and the upper end is open.

[0027] In the above process, the pressing speed is controlled to be 10cm / min; the inner diameter of the rolled pipe is 197mm and the outer diameter is 203mm, and the blanking at the bottom of the long pipe 13 is removed to form...

Embodiment 2

[0030] refer to figure 1 , AgCuV 10-0.2 The silver-copper-nickel alloy of the brand is smelted into a square ingot in a vacuum intermediate frequency furnace, and then rolled into a square plate 11 with a thickness of 4.5mm and a side length of 450mm, and then annealed in a box-type resistance furnace at an annealing temperature of 700°C and a holding time of 60min .

[0031] The 400-ton two-way hydraulic press exerts pressure on the plate, the periphery of the plate is fixed, and the center moves downward to form a C-shaped concave structure 12 in section.

[0032] Continue to apply pressure to roll the C-shaped concave structure 12 into a long tube 13 with a U-shaped cross-section. The low end of the long tube 13 is closed and the upper end is open.

[0033] In the above process, the pressing speed is controlled to be 10cm / min; the inner diameter of the rolled pipe is 192mm and the outer diameter is 197mm, and the blanking at the bottom of the long pipe 13 is removed to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com